T O 35C2-3-442-2

P-8-627-34

TM 5-6115-457-34

TM-07464A-35

1. Rack bearing bore.

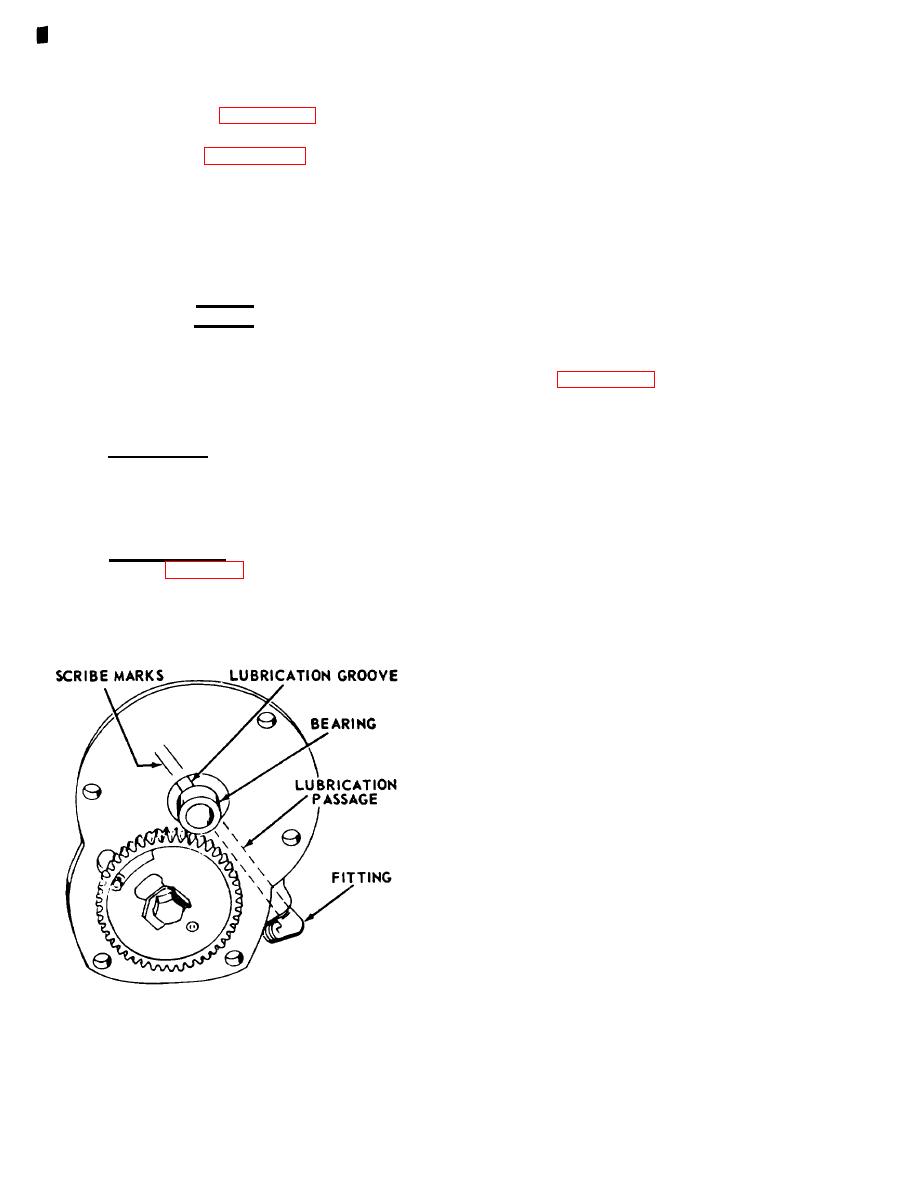

f. When removing fuel regulator rack

bearings (62 and 65, figure 8-39), first

2. Fuel rack diameter.

make two scribe marks on housing above

groove on bearing (figure 8-40). This

3. Fuel rack to bearing clearance.

procedure allows for the alignment of

groove on bearing with drilled lubrication

4 . Camshaft bearing bore.

passage during reassembly.

g. Wire together each spacer (55, fig-

ure 8-39) and fuel pump lifter (56). Tag

5 . Camshaft bearing journal

each pair and identify the pump bore from

diameter.

which they were removed.

WARNING

6 . Camshaft to bearing clearance.

Cleaning Solvents are flammable and

7. Pump plunger length. Inspect

moderately toxic to skin, eyes and

plungers (52, figure 8-39) for excessive

respiratory tract. Eye and skin

wear on end which makes contact with

protect ion required. Good general

lifting washers (55 ). Length of new plunger

ventilation is normally adequate.

is 2.5931 to 2.5937 inches. The minimum

8-144. CLEANING.

allowable length that a worn plunger may

Clean metal components with an

continue to be used is 2.5881 inches.

approved cleaning solvent to remove fuel

oil, dirt, and accumulated deposits, and

NOTE

dry thoroughly.

8-145. INSPECTION.

Whenever a plunger is replaced, it

a. Refer to table 1-1, and using a

is necessary to replace the entire

suitable micrometer and feeler gauge,

pump assembly.

check for excessive wear as follows:

8. If allowable limits are not met

on above parts, replace part.

b. Inspect pump housing (76) for cracks,

breaks, and clogged oil passages.

c. Inspect the drive tang on camshaft

(60) and drive sleeve (59) for signs of

wear.

d. Inspect camshaft (60) for damaged

lobes.

e. Inspect plunger and barrel assembly

(48), lifter assembly (56), and washer (55)

for excessive wear or damage.

f. Inspect fuel rack (40) for nicks and

burrs and for chipped or cracked gear

teeth. If gear segments are cracked or

Figure 8-40. Removing fuel r e g u l a t o r

chipped, replace fuel rack.

rack bearings

8-90

Change 8