T. O. 35C2-3-442-2

P-9-TM-457-35

TM 5-6115-457-34

TM-07464A-35

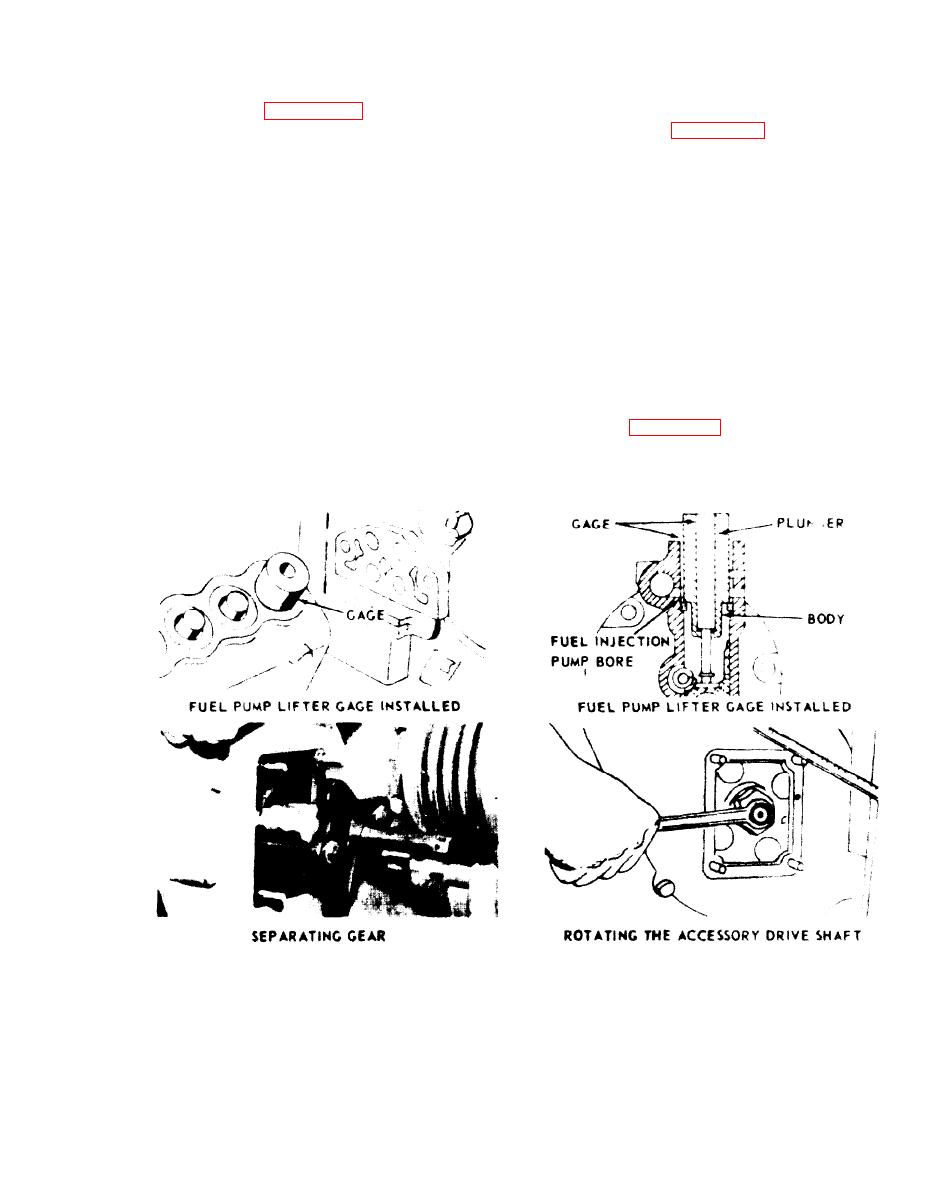

b. FUEL INJECTION PUMP TIMING

2. Apply 1875 PSI to the valve

DIMENSION CHECK AND ADJUSTMENT -

assembly (13, figure 8-39), a satisfactory

ON ENGINE (See figure 8-44).

valve should emit a complete atomized

spray with a sharp cut-off of fuel and no air

1. Remove two bolts and lockwash-

dribble. If the valve assembly (13) emits a

ers and timing pointer cover from flywheel

solid stream of fuel with little or no

housing.

atomization, replace the nozzle assem-

bly (16).

2. Remove fuel injection pump for

Cylinder No. 1 as outlined in para-

3. Valve assembly (13) unseating

graph 8-143.

pressure should be between 400 to 800 PSI.

If valve assembly fails to reach a minimum

3. Rotate crankshaft counterclock-

of 400 PSI, replace valve assembly (13).

wise (as viewed from flywheel end) at least

Reduce gauge pressure to 300 PSI. Observe

60 degrees. Continue rotating crankshaft

the gauge and note whether leakage causes

counterclockwise until TC1-6 CYL mark

an additional drop in pressure. If the pres-

on flywheel is aligned with timing pointer

sure falls more than 100 PSI in 30 seconds,

as shown in figure 8-45 and both the inlet

replace the nozzle assembly (16).

Figure 8-44. Fuel injection timing on the engine

8-93