T O 35C2-3-442-2

P-8-627-34

TM 5-6115-457-34

TM-07464A-35

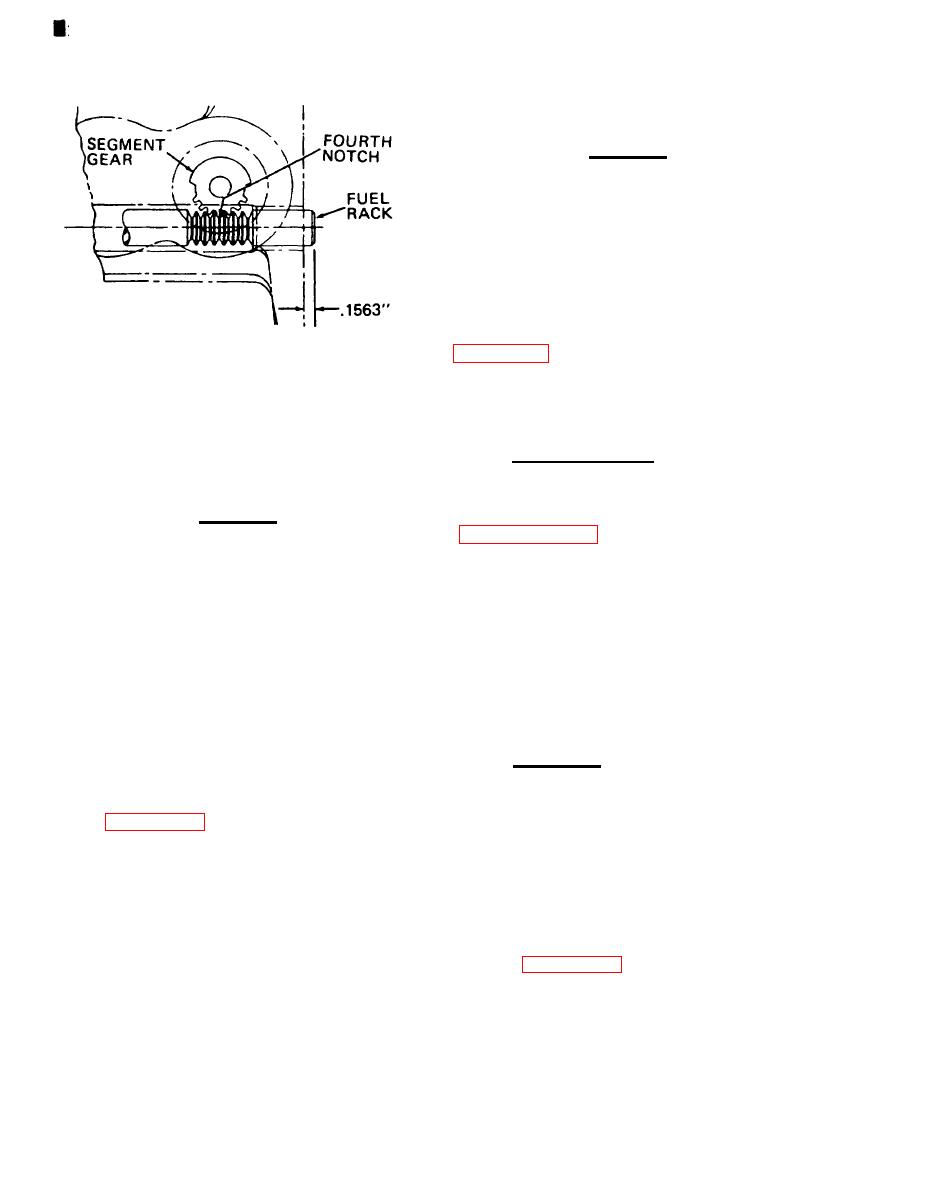

that the gear segment is properly posi-

tioned with the rack.

CAUTION

An injection pump improperly in-

stalled in the "fuel on" side posi-

tion of its gear segment can cause

an engine to overspeed with

resulting serious damage to the

engine and driven equipment.

h. Torque nozzle retaining nut (14,

Figure 8-43. Correct position of gear

segment and rack

i. Torque fuel line nuts from 25 to

35 foot-pounds.

f. Tighten each pump bushing (42, fig-

8-148. INSTALLATION.

ure 8-39) to a torque value of 140 to

160 foot -pounds.

a. Installation of the fuel injection

group is accomplished during reassembly

CAUTION

A misaligned fuel injection pump

b. Install utility governor group (para-

can cause an engine to overspeed

graph 8-140).

with resultant damage to engine,

t u r b o c h a r g e r , and compressor.

c. Refer to Operator and Organiza-

tional Maintenance Manual and install

g. Measure the rack travel to make

overspeed switch, hydraulic oil filter (pre-

sure that the plunger gear segment is

cise generator sets only), and secondary

properly meshed with the fuel rack. The

fuel filter and relief valve group.

gear segment and rack are so constructed

that the maximum travel of the rack in

8-149. TESTING.

either direction can be obtained only when

the fourth tooth of the gear segment is

a. TEST FUEL INJECTION VALVES

meshed with the fourth notch on the fuel

FOR SPRAY CHARACTERISTICS, VALVE

rack (figure 8-43). If the gear segment is

OPENING PRESSURE AND LEAKING

misplaced in either direction, the rack

RATE. Using a suitable diesel injector

travel will be reduced in both directions.

pump test stand and diesel injector tool

It is, therefore, necessary to measure the

test set, perform the following:

rack travel in only one direction to make

certain that the gear segment is properly

1. Before testing the valve assem-

meshed with the fuel rack. This is meas-

bly (13, figure 8-39), inspect screen filter.

ured by using the rack setting gauge (fig-

If the screen is broken or clogged, discard

ure 8-41). The rack is moved to its

extreme fuel on position. A minimum

the valve assembly (13). If the screen ap-

pears normal, test the valve assembly (13).

reading of +0.312 on the gauge indicates

8-92

Change 8