P-8-627-34

T O 35C2-3-442-2

TM-07464A-35

TM 5-6115-457-34

g. Inspect threaded holes for damaged

threads.

h . Discard seals.

8-146. REPAIR.

a. Repair minor nicks and burrs on

fuel rack (40, figure 8-39) using a suitable

file or hone.

WARNING

Fuel Oil if flammable and moderately

toxic to skin, eyes and respiratory

t r a c t . Eye and skin protection re-

quired. Good general ventilation

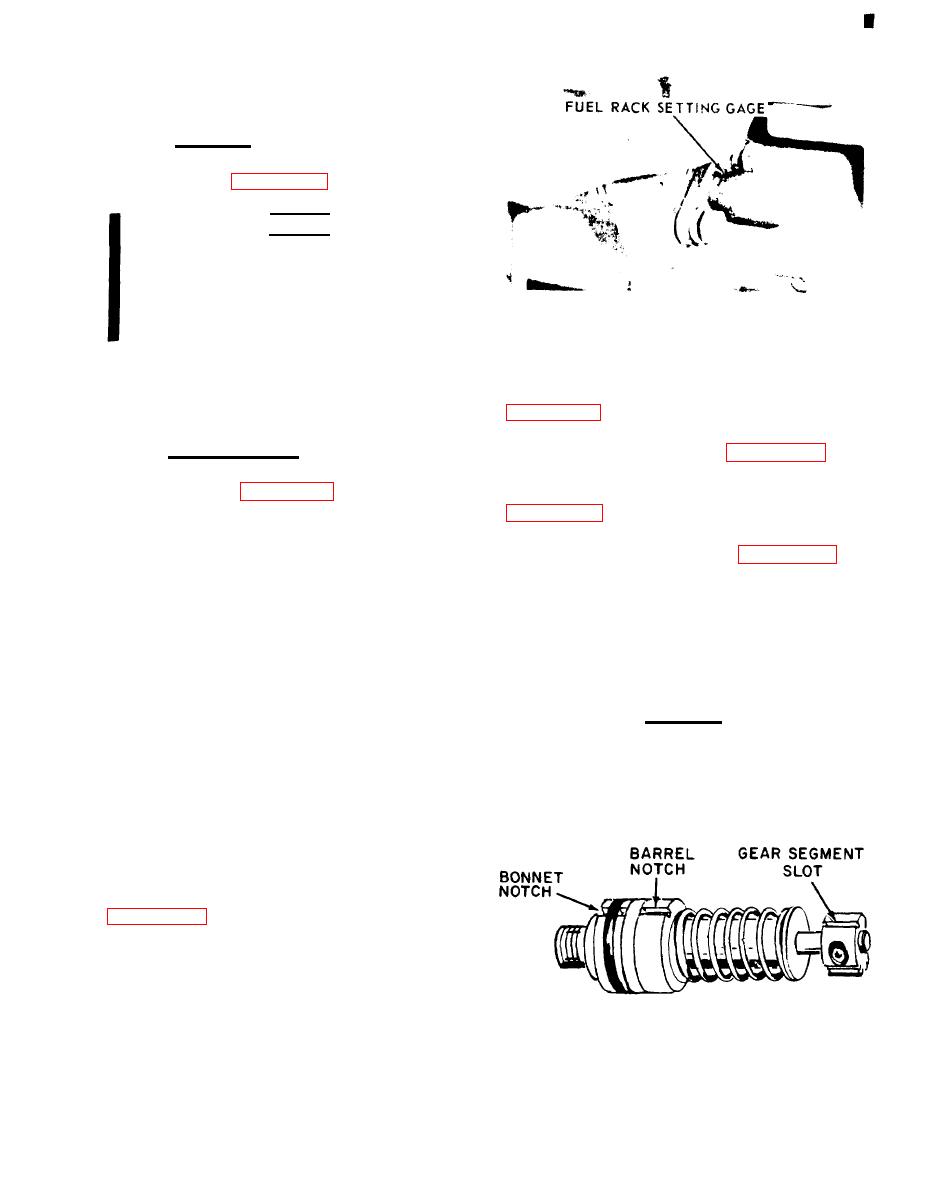

Figure 8-41. Installing regulator fuel rack

is normally adequate.

b. Ream out clogged passages in hous-

ing (76) with a thin flexible wire. After

pump, align the notches in the bonnet (44,

cleaning passages, flush with fuel oil.

c. Repair minor thread damage using

alignment mark 180 degrees from the pump

a suitable thread chaser.

8-147. REASSEMBLY.

gear segment center tooth {figure 8-42).

Position pump so that the notches align

Refer to figure 8-39 and reassem-

with the two locating dowel pins (70 and 72,

ble fuel injection group in the reverse order

of index numbers assigned. Pay particular

pump gear segment center tooth with fuel

attention to the following:

regulator rack center notch (figure 8-43).

Install pump. Keep a downward force on

a. All assembly should be done with

the pump, and install bushing (42, fig-

clean hands and on a clean, lint-free cloth.

ure 8-39) until flush with the top of the

housing. If the bushing cannot be installed,

b. Using a suitable installing tool,

this far by hand, remove bushing, realign

install camshaft bearing (63) so that hole in

component parts, and install again.

bearing aligns with oil passage in housing

(76) and is flush with housing face.

CAUTION

When tightening bushing (42), a

c. Install fuel regulator rack bearings

lesser torque value will allow pump

(62 and 65) so that groove in bearings

aligns with scribe marks on housing (76).

to leak; a greater torque value can

Bearing (65) must be installed 0.195

damage housing.

0.005 inch deep from the housing face.

d. Use a suitable fuel rack setting

gauge when installing fuel regulator rack,

so that gauge indicates 0.00 inch.

e. Use the same extractor that was

used to remove each pump to install each

fuel injection pump. Sighting down the

Figure 8-42. Fuel injection pump alignment

8-91

Change 8