T . O . 35C2-3-442-2

P-9-TM-457-35

TM 5-6115-457-34

TM-07464A-35

conditions with highly skilled mechanics,

n. TIME STANDARDS. Table 1-3

most of the operations can be accomplished

lists the number of man-hours required

under normal conditions to perform the

in considerably less time.

indicated maintenance and repair for the

o. SCHEMATICS AND WIRING DIAGRAMS.

g e n e r a t o r sets. Components are listed

under the appropriate functional index. The

and wiring diagrams for the 50/60 and 400

times listed are not intended to be rigid

standards, Under adverse conditions, the

hertz generator sets, their components and

auxiliaries.

operations will take longer, but under ideal

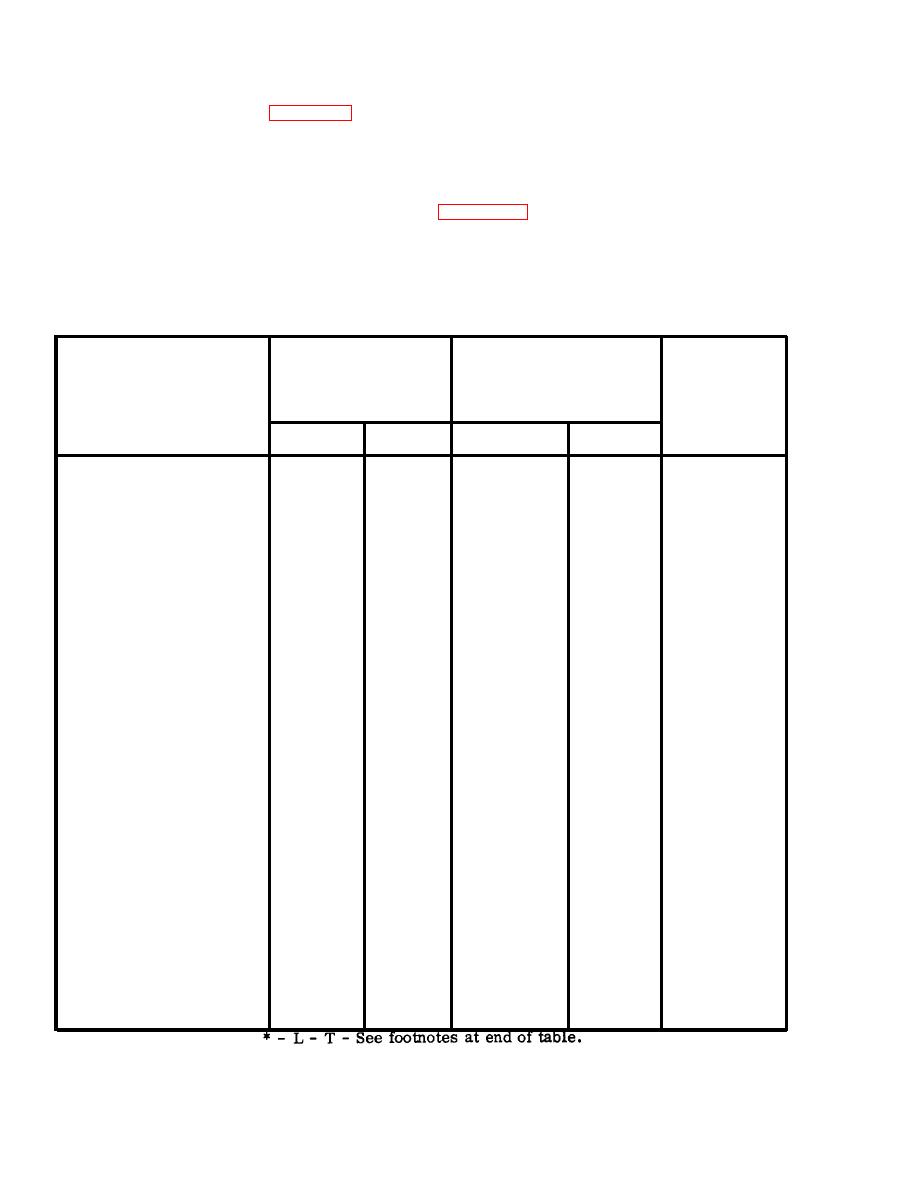

Table 1-1. Repair and Replacement Standards

MANUFACTURER'S

MAXIMUM

DIM ENSIONS AND

ALLOWABLE

TOLERANCES

WEAR AND

DESIRED CLEARANCE

COMPONENT

IN INCHES

CLEARANCE

MAX

MIN

MAX

MIN

tarting Motor Assembly:

0.7500

-

0.3750

Brush length

Thrust washer thickness

(Commutator end of

0.0930

0.0312

0.0250

armature shaft).

Thrust washer thickness

(Drive end of armature

0.0900

shaft).

0.0950

Thrust washer thickness

0.0280

(Intermediate bearing)

0.0312

Maximum end play of

0.0300

0.0500

armature

Thrust washer thickness

*

0.0650

(Outer washers)

0.2810

0.2740

0.2790

Yoke pin diameter

*

0.2820

0.2830

Yoke bore for pin

*

0.0040L

0.0010L

Fit of pin in yoke

*

0.0050L

0.0010L

Fit of pin in cover

1-30