TM 5-6115-400-12

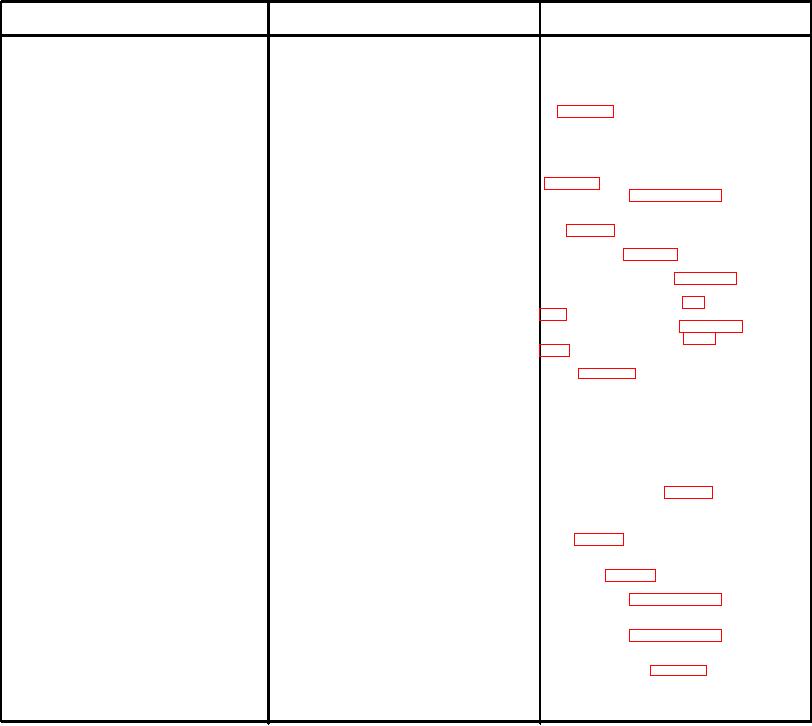

Table 3-3. Troubleshooting Continued

Malfunction

Probable cause

Corrective action

14.

Lubricating oil overheats

a.

Insufficient oil in crankcase.

a. Fill crankcase to proper

level.

b.

Improper lubricant.

b. Drain and fill crankcase

with specified lubricant.

c.

Engine oil cooler clogged.

c. Clean or replace the oil cool-

er (para 3-28).

15.

Batteries will not hold

a.

Loose terminals or connec-

a. Check and tighten.

charge

tions.

b.

Short in electrical sys-

b.

Check cables and wiring.

tern.

c.

Defective battery.

c. Replace defective battery

d. Generator regulator not op-

d. Refer to paragraph 3-58.

erating properly.

16.

Main generator fails to

a. Voltage not adjusted to the

a. Adjust voltage control rheo-

build up to rated voltage

selected operating voltage.

stat (fig. 2-9) to agree with

or output voltage too low

selected voltage.

b. Improper generator peat-

b. Refer to para 2-11 for appli-

ing procedure.

cable operating details.

c. Loose terminal connections

c. Stop the engine (para 2-12),

on voltage reconnection panel.

and tighten all connections at

voltage reconnection panel (fig.

d.

Brushes defective.

d. Replace brushes (para 3-82).

17.

Voltage drops under load

a.

Brushes defective.

a. Replace brushes (para

b. Unit paralleling switch de-

b. Replace unit paralleling

fective.

switch (para 3-65).

18.

Main generator overheats

a. Generator louver doors

a. Open louver doors.

Closed.

b. Generator ventilating louvers

b. Remove obstructions from

or screens obstructed.

louvers and screens.

c. Operating area not adequate-

c. Increase ventilation in the

ly ventilated.

operating area.

d. Generator overloaded.

d. Reduce the load and report

the condition to righer echelon.

19.

Main Generator Fails to

a. Circuit breaker is in OFF

a. Throw circuit breaker to ON

Supply Power to Load

position.

position at proper time (figs. 2-9

and 2-110).

Warning: Make sure unit is shut down before performing work on load cables or load terminal.

b. load cables not connected

b. Reconnect load cables cor-

correctly.

rectly (para 2-5).

c. Load cables defective

c. Replace the load cables.

d. Load terminal studs defe-

d. Clean and tighten load ter-

tive or loose.

minal studs (para 2-5) or replace

studs.

20.

Generator fails to maintain

a. Generator frequency fluc-

a. Refer to paragraph 2-14.

KW load division during

tuates or drifts.

parallel operation

b. Generator frequency drops

b.

Refer to paragraph 2-14.

under load.

c. Unit-parallel switch not in

c. Place unit-parallel switch in

PARALLEL position.

PARALLEL position (fig. 2-10).

d. Paralleling cable not secure-

d

Reconnect paralleling cable

ly connected.

securely.

3-15