TM 5-6115-400-12

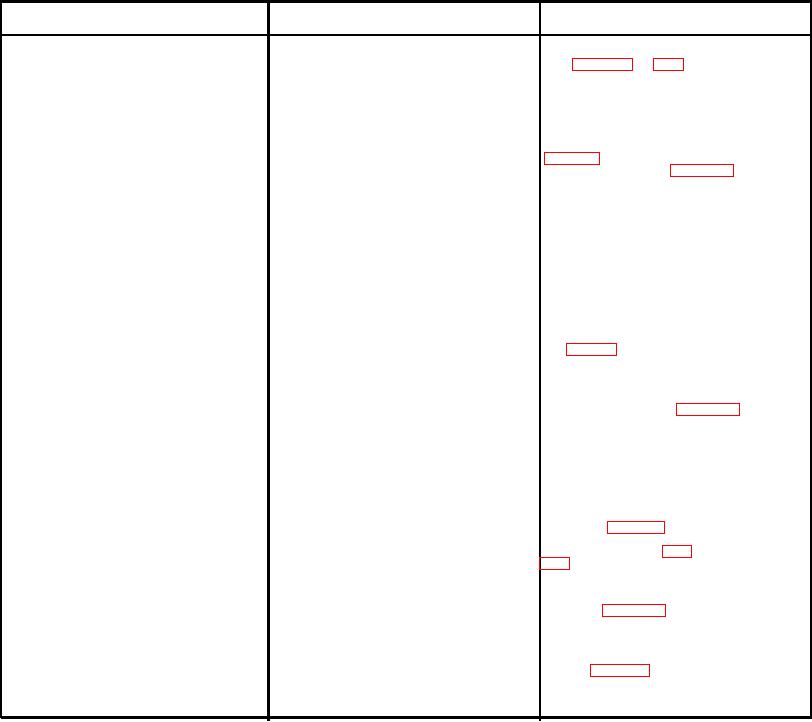

Table 3-3. Troubleshooting--Continued

Malfunction

Probable cause

Corrective action

g. Inoperative fuel injection

g. Repair or replace affected

pump or fuel injection nozzle.

parts (paras 3-32 and 3-33).

6.

Engine Runs Uneven and

a. Governor not operating

a. Refer to higher echelon.

Excessive Vibration

properly.

b. Fuel supply erratic or in-

b. Check fuel stem (para

sufficient.

3-29).

c. Engine operating tempera-

c. Check thermostats (par

ture too low.

3-47).

d. Fuel injection pump malfunc-

d. Replace fuel injection pump

tions.

e. Fuel injection nozzle mal-

e. Replace nozzle (para 3-33).

functions.

7.

Engine detonates

a. A hard metallic knock indi-

a. Check for leaky fuel injec-

cates detonation in one or more

tion nozzles or improper timing

cylinders, the engine must be

of fuel injection pump (para

stopped immediately to prevent

3-32).

serious damage due to the ex-

cessive pressures accompanying

the detonation. Detonation is

caused by the presence of fuel or

lubricating oil in the charge of

air that has been delivered to

the cylinder during the compres-

sion stroke.

8.

Engine emits black smoke

a. Air system clogged.

a. Check engine air intake sys-

from exhaust

tem (para 3-8).

b.

Improper fuel.

b. Drain fuel system and refill

with fuel of proper specification

9.

Engine emits blue

a. Engine operating tempera-

a. Check thermostat (para

ture too low.

3-47).

b. Fuel injection nozzles not

b. Replace nozzles (para 3-33).

operating properly.

10.

Starter will not crank

a. Batteries weak.

a. Check batteries (para 3.62).

engine

b. Cables mad/or connections

b. Tighten all loose connections

loose or corroded.

and clean corrosion from all ter

minals.

c. Starter solenoid switch in-

c. Replace solenoid switch (pare

operative

3-56).

d. Starter brushes worn or not

d. Install new brushes or fit

contacting properly.

brushes to conform to contour of

commutator (para 3-82).

e. DC control circuit breaker in

e. Push DC control circuit

OFF position.

breaker to ON position (para

11.

Starter pinion will not

Grease and/or dirt in start

Refer to direct and general sup-

engage flywheel gear

mechanism.

port maintenance

12.

Low oil pressure

a. Oil pressure relief valve or

a. Clean, replace af-

regulator valve stuck in open

fected part (paras 3-26 and

position.

3-27).

b. Improper lubricant.

b. Fill crankcase with specified

lubricant.

13.

Excessive oil pressure

a. Oil pressure regulating valve

a. Adjust valve to obtain proper

improperly adjusted.

pressure (para 3-27).

b. Improper lubricant.

b. Drain and fill crankcase with

specified lubricant.

3-14