TM 5-6115-400-12

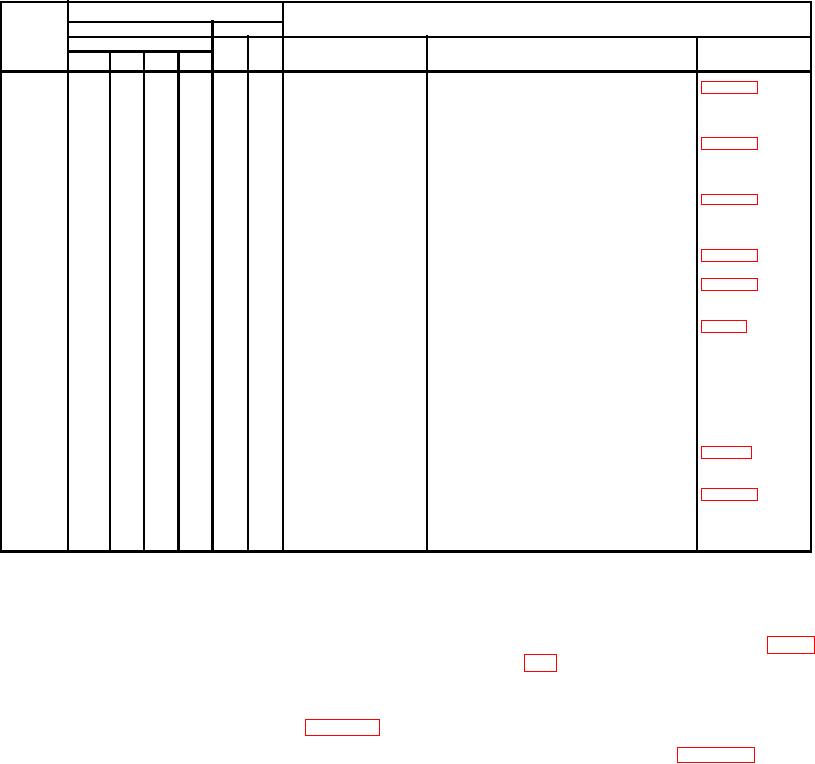

Table 3-2. Preventive Maintenance Checks and Services-Continued

Interval

B - Before operation

A - After operation

M - Monthly

Item

Operator

Org.

D - During operation

W - Weekly

Q - Quarterly

Number

Daily

B

D

A

W

M

Q

Item to be inspected

Procedure

Reference

8

*

*

Fire extinguisher

Check for broken seal. Weigh

new or charred extinguisher

4 ounce loss maximum.

4

*

*

*

*

Ground terminal

Check for adequate grounding.

5

*

*

*

Collector manifold

Open drain cock daily. Leave

open during shutdown period.

Drain cock MUST be closed

during engine operation.

6

*

*

*

Fuel tank

Fill as necessary. Clean cap

vent.

7

*

*

*

*

*

*

Oil level gage

Keep oil at "FOLD" on indicator.

Check current lubrication order.

8

*

*

*

Fuel filters

Drain sediment and water from

fuel filters.

9

*

*

*

Hydraulic tank

Check fluid level, add fluid as

required.

*

Inspect defective tank.

10

*

*

*

*

Batteries

Tighten loose connections. Re-

move corrosion. Check for

cracks and leaks. Fill to 3/8

inch above plates. Clean vent

holes in caps. Replace a

cracked battery.

11

*

*

Radiator

Coolant lever is 2 inches below

para 3-46

neck. Correct cap pressure

is 7 lbs.

12

*

Air cleaner

Check restriction indicator.

13

*

*

Vibration or noise

Be on alert for unusual noise

or excessive vibration.

14

*

*

Main generator

Check for frayed wiring. Clean

brushes and

or smooth dirty or rough slip-

sliprings.

rings. Replace brushes if worn

to 1/2 original size.

Section IV. OPERATOR'S MAINTENANCE

3-7. General

3-9. Fuel Tank

The instructions in this section are published for the

a. Fuel Tank Cap and Strainer.

information and guidance of the operator to maintain the

(1) Removal and Installation. Refer to figure

generator set.

3-3 and remove the fuel tank cap and

gasket and strainer.

3-8. Air Cleaner

b. Fuel Drains.

Check air restriction indicator daily. If red signal is

(1) Fuel drains are located at both corners of

visible, service the air cleaner as described in figure 3-2.

the fuel tank at the control panel end of

the generator set. See figure 3-4.

3-6