TM 5-6115-400-12

in an amount sufficient to wear out the turbocharger

oil is contaminated, turbocharger damage can result.

bearings or when the contaminating particles are large

Some examples of instances where the filter will be

enough to plug the internal oil passages and starve the

bypassed are:

turbocharger for oil.

(1) When the oil filter is clogged and the

c. Use of Time Totalizing Meter to Determine

bypass valve is open.

Lubricating Intervals. The established intervals in the

(2) When a lube valve or filter bypass valve

lubricating chart and maintenance instructions are given

malfunctions (as a result of worn or

in service hours. The intervals indicated are for normal

binding components).

service.

Contaminated oil will actually cause damage to the

turbocharger bearings when this oil is permitted to enter

Section III. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

operation were continued.

All deficiencies and

3-5. General

shortcomings will be recorded together with the

To insure that the generator set is ready for operation at

corrective action taken on DA Form 2404 at the earliest

all times, it must be inspected systematically, so that

possible opportunity.

defects may be discovered and corrected before they

result in serious damage or failure. The necessary

Preventive Maintenance Checks and Services to be

3-6. Preventive Maintenance Checks and Services

performed are listed and described in paragraph 3-6.

This paragraph contains a tabulated listing of preventive

The item numbers indicate the sequence of minimum

maintenance services which must be performed by the

inspection requirements. Defects discovered during

operator. The item numbers are listed consecutively

operation of the unit shall be noted for future correction,

and indicate the sequence of minimum requirements.

to be made as soon as operation has ceased. Stop

operation immediately if a deficiency is noticed during

operation which would damage the equipment if

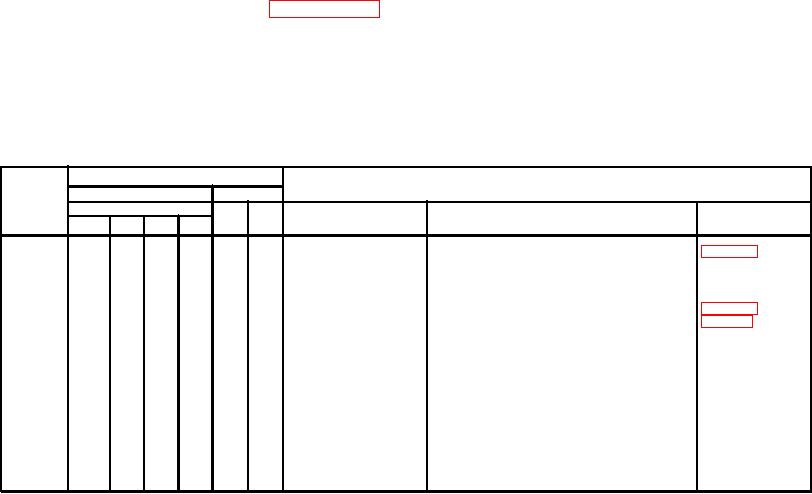

Table 3-2. Preventive Maintenance Checks and Service

Interval

B - Before operation

A - After operation

M - Monthly

Item

Operator

Org.

D - During operation

W - Weekly

Q - Quarterly

Number

Daily

B

D

A

W

M

Q

Item to be inspected

Procedure

Reference

1

*

*

*

*

*

V Belts

Proper adjustment for drive

belts is a deflection of 1/2 to

3/4 inches midway between

2

*

*

*

*

*

*

Controls and in-

Inspect for damage or loose

struments

mounting. Check for proper

operation. Normal operation

readings for instruments are

as follows:

Ammeter-Green portion of scale

Coolant temperature-160 to 200F

Oil pressure-30 to 60 psi

Voltmeter-120/208-24/416 volts

AC Ammer-100% maximum

Wabtmter-200 KW maximum

Frequency mete--50/60 cycles

Fault indicator-All lights out

3-5