TM5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

i.

Time delay TD2 (87, figure 5-1).

(1)

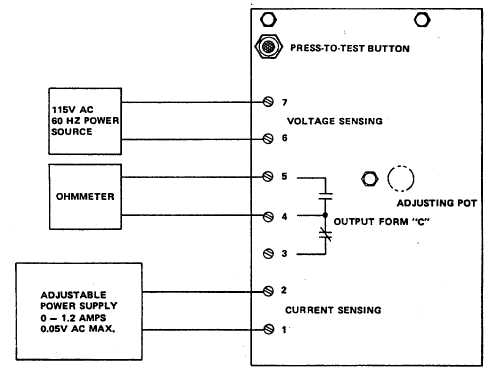

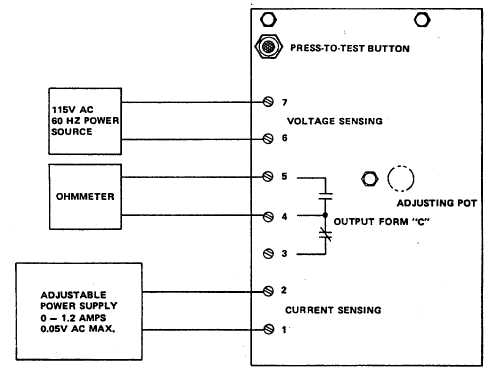

Tests for Replacement Components. Check

the following components on TD 2, figure 5-

14.

(a)

Check transistor Q1 by connecting to

transistor tester and testing for current gain

or 100 min, leakage, or short.

(b)

Check capacitors C1 and C2 by connecting

each to a capacitor tester and checking for

leakage and capacitance. C1 must read 10

microfarads, 25 volts, ±5 percent. C2 must

read 47 microfarads, 50 volts, ±10 percent.

(c)

Check resistors, using an ohmmeter, for the

following resistances.

R4

820 ohms, 25 watts, ±5 percent

R1

2 k megohms, 1 watt, ±5 percent

R2

2.7 megohms, 25 watts, ±5 percent

R3

390 k, 0.25 watt, ±5 percent

WARNING

BEFORE

STARTING

ANY

MAINTENANCE PROCEDURE, SET

MAINTENANCE LOCKOUT SWITCH

TO

LOCKOUT.

DISCONNECT

NEGATIVE

CABLE

FROM

BATTERIES. REMOVE EXTERNAL

POWER

BY

OPENING

CB101

(EXTERNAL

POWER

CIRCUIT

BREAKER) AND DISCONNECTING

POWER CABLE FROM RECEPTACLE

J101 (120V RECEPTACLE).

(2)

Test of TD2.

(a)

Connect time delay circuit as shown in

figure 5-14.

(b)

Close switch S1. Time the period it takes

before lamp DS1 lights. It must be 3.5 to

4.5 seconds or TD is defective.

(3)

Repair. If any of the replaceable components

tested in 1 (above) are defective, TD2 is

repairable

by

replacing

the

defective

component. If the printed circuit wiring or a

terminal

Figure 5-11. Reverse Power Relay K112, Test Setup

5-14