T.O. 35C2-3-442-2

P-9-TM-457-35

TM 5-6115-457-34

TM-07464A-35

i s tripped, the solenoid plunger should

r e l e a s e (move out of the solenoid) and

This movement of the

r e m a i n released.

s o l e n o i d plunger should rotate the

m a n u a l fuel rack lever clockwise to

almost full off position.

c . UTILITY GOVERNOR SPEED SETTING

Adjust utility governor

ADJUSTMENT.

l o w and high speed stops as follows:

1. L o o s e n nut (5, figure 8-33)

and turn low speed stop screw (4)

c o u n t e r c l o c k w i s e until it is free of

s p e e d e r spring (46).

CAUTION

Do not crank engine for more

than 15 seconds at a time.

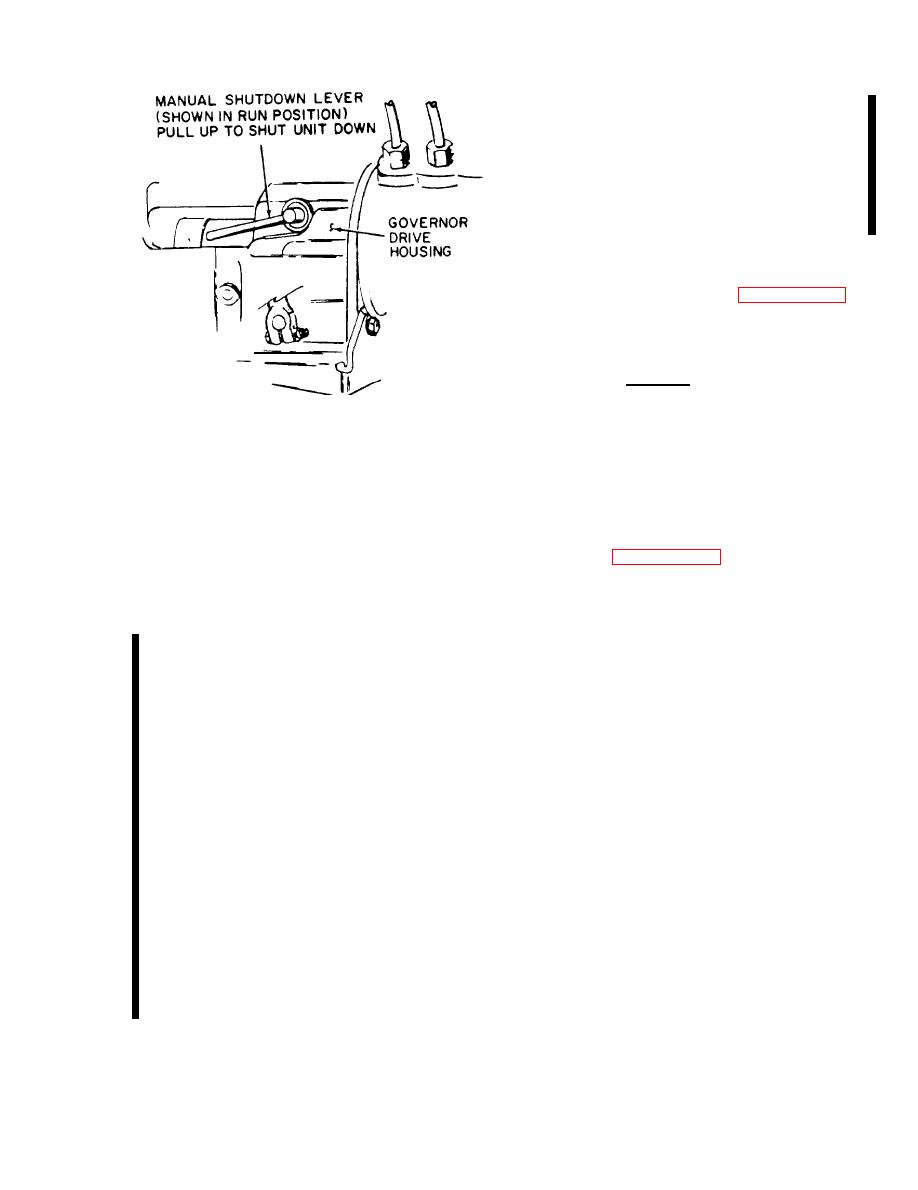

Figure 8-66. Location of manual fuel

P e r m i t starter to cool a mini-

shutdown lever

mum of three minutes between

crankings.

3. T u r n engine over using starter

u n t i l oil pressure builds up to 50 10

2. Crank engine over with

PSIG.

starter and turn low speed stop screw

O i l pressure should build up

within 15 seconds.

( 4 ) clockwise until governor output

shaft (13, figure 8-33) rotates, opening

f u e l rack. Continue turning low speed

Release manual fuel shutdown

4.

Inspect all fluid systems for

lever.

s t o p screw until engine starts.

s i g n s of leakage.

3. Permit engine to run a mini-

mum of five minutes for warmup and

b. OPERATIONAL TEST OF OVERSPEED

a d j u s t low speed stop screw (4) to

SHUTDOWN DEVICE.

obtain 800 RPM idle speed.

Clockwise

r o t a t i o n will increase speed. Hold screw

1. Dead crank engine and deter-

i n position and tighten nut (5). Recheck

n i n e if solenoid plunger (2, Figure

If the sole-

RPM setting.

8 - 3 1 A ) pulls in (bottoms).

noid plunger does not bottom or does not

4. R o t a t e speed adjusting shaft

have enough power to overcome the spring

(25) to maximum speed position and moni-

tension, increase the measurement

tor engine RPM. Do not exceed 2300 RPM.

between the bushings (6 and 9, Figure

3-31A) by adjusting bottom bushing.

5. Engine high speed stop

setting should be 2250 RPM. To adjust

2. Each time the engine is

h i g h speed stop, loosen nut (20) and

s t a r t e d , the solenoid plunger should

r o t a t e high speed stop screw (19) to

p u l l in (bottom) and remain pulled in.

obtain 2250 RPM when speed adjusting

This movement of the solenoid plunger

shaft (25) is in maximum speed position.

s h o u l d rotate the manual fuel rack lever

C l o c k w i s e rotation will increase engine

c o u n t e r c l o c k w i s e to almost full on

RPM setting. T i g h t e n lock nut and re-

position.

check RPM setting.

3. Each time the engine is

I f engine s u r g e s during

6.

stopped or t h e governor overspeed switch

8-147

Change 2