TM 5-6115-400-35

e. Valve Seat Inserts.

mended press fit cannot be obtained when installing new

(1) Removal. Inspect the valve seat inserts.

standard size valve seat inserts, the bores must be

If they are loose, cracked or pitted, new

machined .005 inch larger than their original I.D. and

inserts must be installed. The valve seat

.005 inch oversize valve seat inserts must be installed.

inserts are a press fit in the cylinder head.

Refer to table 2.1 for O.D. of valve seat inserts and

Remove valve seat inserts by electric

corresponding I.D. of bores in cylinder head. The

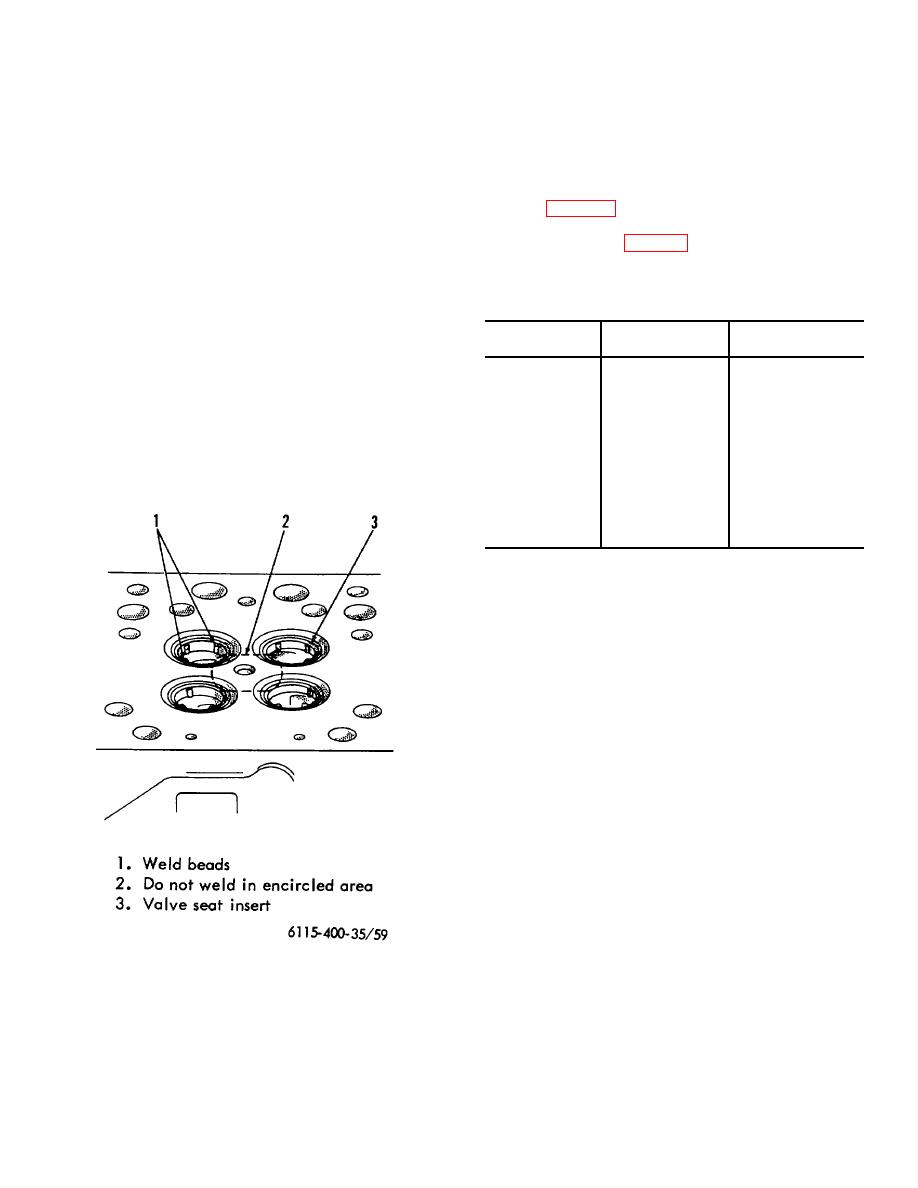

welding three small beads on inside

dimensions shown in table 2.1 provide an interference fit

circumference of the insert as shown in

of .002 inch to .004 inch for intake valve seat inserts

figure 59. Allow insert to cool, then lift out

and .002 inch to .0035 inch for exhaust valve seat

or pry out with a bar.

inserts.

Caution

Table 2.1. Valve Insert Dimensions

Do not weld in encircled area (fig.

Valve Seat

O.D. of New

Insert Bore in

59). Protect machined surfaces from

Insert

Insert

Cylinder Head

arc splatter.

Standard

(2) Installation.

Size-Intake 1.6445 inch-

1.6415 inch-

(a) It is imperative that the original

.005 inch

1.6455 inch

1.6425 inch

press fit be maintained between

Oversize-

1.6495 inch-

1.6465 inch-

new inserts and insert bores in the

Intake

1.6505 inch

1.6475 inch

cylinder head. If insert bores in

Standard

cylinder head are damaged or worn

Size-

1.6105 inch-

1.6075 inch-

enough so that the recom-

1.6110 inch

1.6085 inch

.005

Oversize-

1.6155 inch-

1.6125 inch-

1.6160 inch

1.6135 inch

(b) Make

certain

valve

seat

counterbores in cylinder head are

clean, free of burrs, and of the

correct size to assure the specified

interference fit (refer to table).

(c) Chill inserts for 2 to 4 minutes in a

dry ice container or cold box.

(d) Place cylinder head bottom side up

on a bench.

Thoroughly clean

counterbores for the inserts with

compressed air and start an insert

into the counterbore (valve seat

side up). Inserts must be started in

place "true" with the counterbore in

the cylinder heads.

(e) Using a valve seat insert installing

tool, drive insert down tightly into

counterbore. This operation must

be done quickly while insert is cold.

Figure 59. Beads welded on valve seat inserts.

93