TM 5-6115-400-35

The usual equipment used with the valve seat grinder

set includes the following items:

(a) Valve seat grinder.

(b) Dial gauge.

(c) Tool pilot.

(d) Four grinding wheels: 150, 300, 450,

and 600.

(3) The cutting face of the stone must be

maintained at the correct angle and in

proper condition by frequent dressing with

a diamond wheel dresser. The frequency

of dressing will be determined by

condition of the seats and amount of

metal required to be removed during the

grinding operation.

(4) By grinding valve face and insert seat at

slightly different angles, a fine line contact

of the face and seat is obtained, thus

eliminating the need to lap the seating

surfaces with grinding compound.

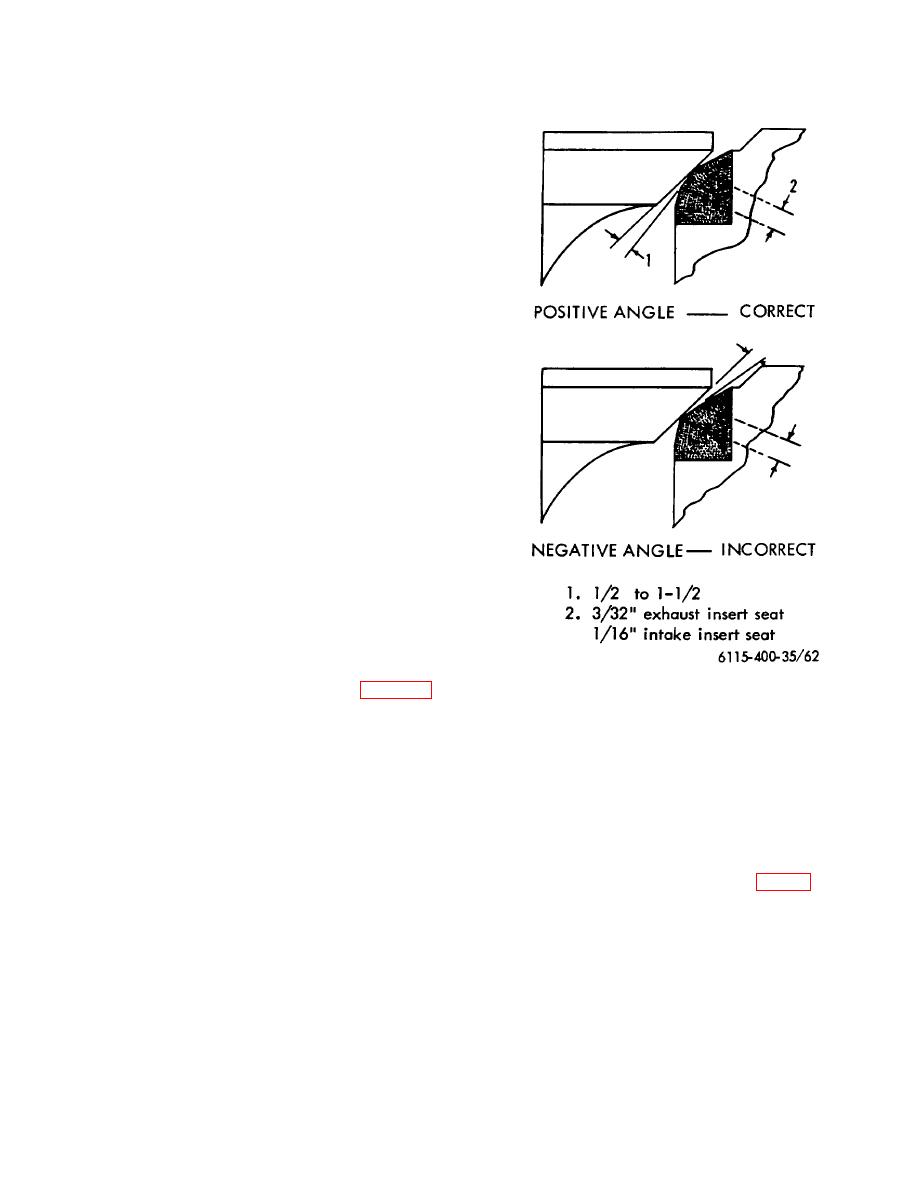

(5) The difference of angles is termed

0

"interference angle" and is usually 1/2 to

0

1 1/2 . The angle of the insert seat is

made greater than that of the valve face,

so as to assure contact at the top of insert

seat. Thus, for the 450 exhaust valve

0

face angle and a 1 interference angle,

the insert seat grinder wheel must be

dressed to grind the insert seat at an

angle of 460. Likewise, the insert seat for

0

the intake valve must be ground at 31 .

This is a positive interference angle. A

Figure 62. Interference angle.

negative angle, as illustrated in figure 62,

film of Prussian Blue on the valve face

must be avoided.

The first step in

and bounce the valve once on the valve

reconditioning the insert is to grind the

seat. A thin, continuous line must be

seat, removing only enough metal to

evident on the valve face, otherwise

produce a pit-free continuous seat. After

further grinding is required.

seat has been ground, use a dial gauge to

Note

check concentricity of the seat relative to

Do not revolve valve while checking

the valve guide. The total run-out of a

good seat should not exceed .002 inch

seat.

total indicator reading.

The specified width of the valve seat on

the insert is 3/32 inch for the exhaust and

(6) To determine seat contact in relation to

1/16 inch for the intake (fig. 62). If the

insert and valve face, wipe a thin

seats are too wide or too narrow they

must be ground to the specified width

using the appropriate angle grinding

wheels.

95