TM 5-6115-400-35

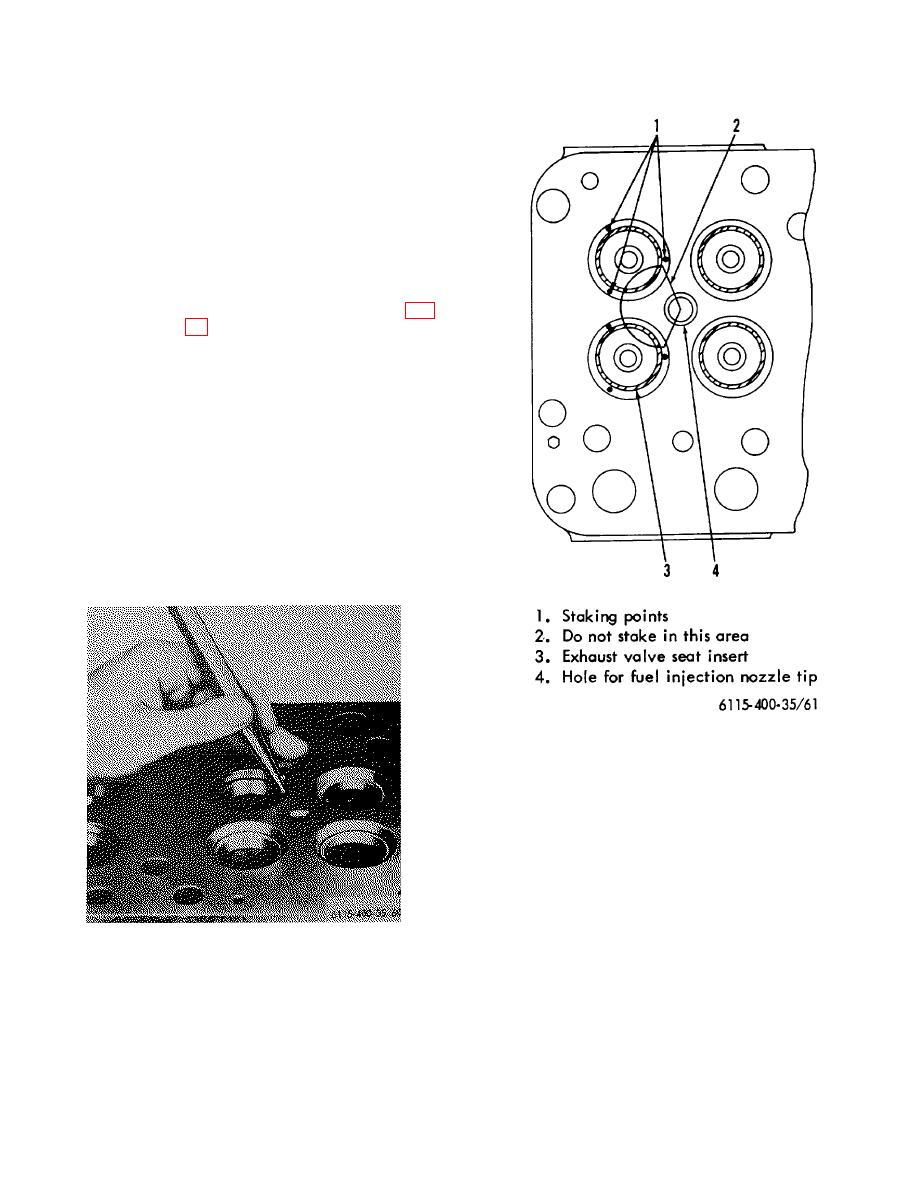

(f) After the inserts have been

installed, the exhaust valve seat

inserts must be staked to eliminate

the possibility of the insert loosening

in its bore. It is not necessary to

stake the intake valve seat inserts.

Using a center punch and hammer,

stake each exhaust valve seat

insert at 3 points approximately

1200 apart, as illustrated in figures

60 and 61, being careful not to

stake in the semi-circled area (fig.

(g) It will be necessary to refinish valve

seat inserts with a grinder (refer to

following para).

f. Valve Face and Valve Seat Grinding.

(1) Before installing either new valves or

valves used previously, valve seats in

cylinder heads should be inspected for

proper valve seating. If previously used

valves are to be reinstalled, valve stems

should be cleaned and valve faces ground

to their specified angles of 45for exhaust

valve and 30for intake valve. When re-

facing valves, remove all evidence of

pitting and grooving. The valve guide

should be cleaned

Figure 61. Exhaust valve seat inserts staking

points.

with a nylon brush. If bore in valve guide

is worn oblong, or if valve head is warped

relative to valve stem, the necessary

parts must be replaced.

(2) When new valve seat inserts are installed,

or previously used inserts re-seated,

refinishing must be done with a valve seat

grinder set.

Note

It is important that the valve grinder

Figure 60. Staking exhaust valve seat inserts.

set be used according to the

manufacturer's directions.

94