(3) Valve Bridge Installation.

(a) Install valve bridges in position on

bridge guide pins and valve stems.

(b) Install rocker arm assembly (para

b. Valve Bridle Guide Pins.

(1) Removal.

(a) Remove cylinder head from engine

(b) Remove valve bridge.

(c) Break bridge guide pin (fig. 54) off

as close to cylinder head as

possible, using a 1/2 inch pipe and

bending pin back and forth until it

breaks.

(d) Using a 5/16 inch drill, drill a hole

approximately 3/4 inch deep in the

center of portion of guide pin

remaining in cylinder head, then tap

the hole with a 3/8 inch NC tap.

Using a 3/8 inch NC

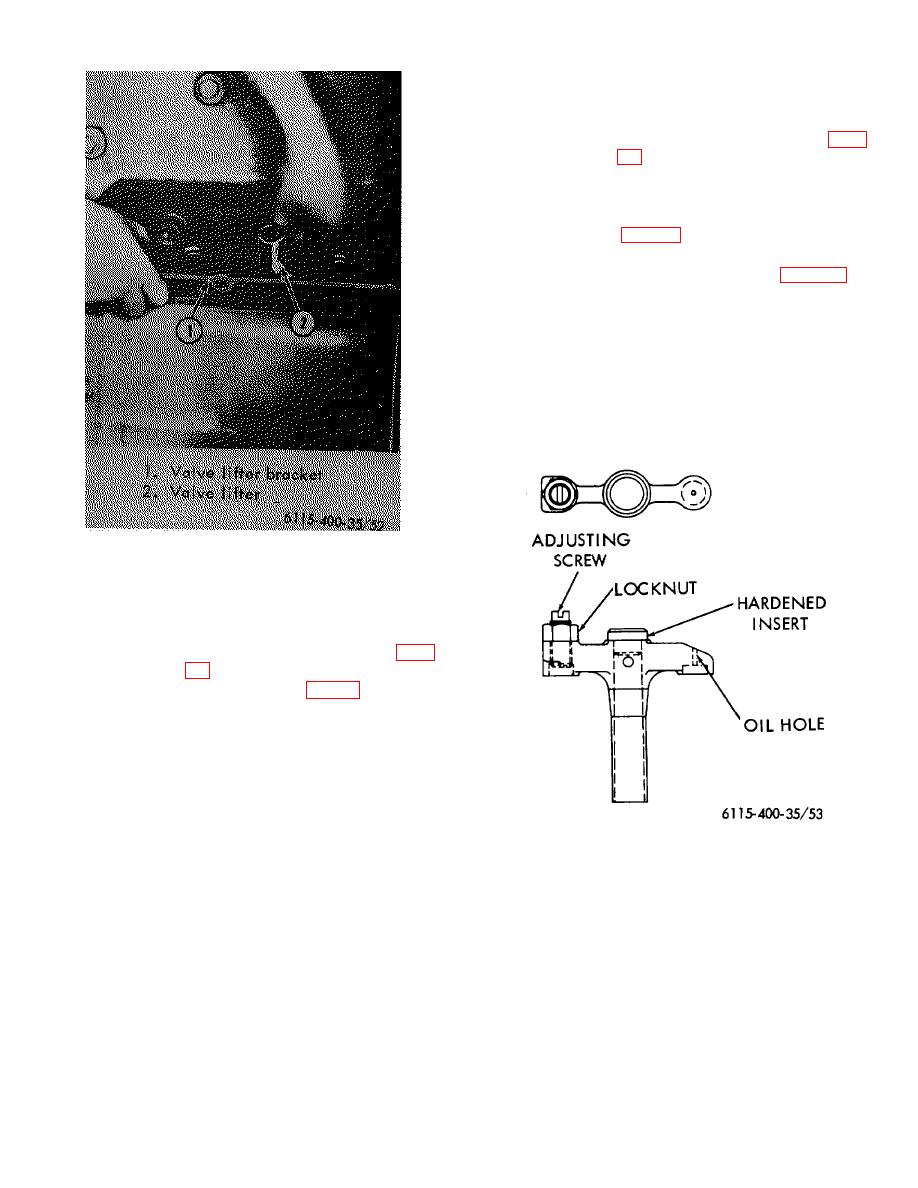

Figure 52. Removing valve lifter from bracket.

45. Valves, Bridges, Springs, Rotators, Guides, and

Seat Inserts

a. Valve Bridges.

(1) Removal.

(a) Remove rocker arm assembly (para

(b) Lift valve bridges (fig. 53) off bridge

guide pins.

(2) Cleaning and Inspection. Clean bridges in

a cleaning solvent. Using a wire, clean oil

hole located in end of cross member

opposite the adjusting screw. Inspect the

hardened insert in top of bridge for wear.

Replace insert if necessary.

The

specified bore in valve bridge guide is

.4995 inch-.5000 inch and specified O.D.

Figure 53. Valve bridge.

of bridge guide pin is .4970 inch-.4975

inch. If total clearance between bridge

and guide pin exceeds .006 inch, replace

bridge and/or guide pin. The bridge must

slide freely on guide pin.

89