TM 5-6115-400-35

Caution

clamps and remove the clamps. Remove

If rocker arms are not marked as

rocker shaft bracket stud nuts and

lockwashers attaching the right side of

described, it is imperative that extra

rocker shaft brackets to the cylinder head.

precautions

be

taken

when

Remove capscrews and lockwashers

disassembling or assembling rocker

attaching the left side of brackets to the

arms to their shafts to be sure they

cylinder head and remove rocker shaft

are installed in their correct

brackets, shaft, and rocker arms as an

locations. Since there is very little

assembly.

visual difference in the rocker arms

c. Disassembly. Remove snap ring at each end of

and to prevent the possibility of the

rocker shaft. After loosening the 5/16 inch capscrews in

rocker arms being mixed and

rocker shaft brackets, and the 1/4 inch centering

improperly reinstalled, each rocker

capscrew in the middle bracket, slide rocker arms,

shaft assembly should be kept

brackets, rocker arm retainers, and spring retainers from

separate and rocker arms punched or

the shaft.

marked in some way before removal

d. Cleaning and Inspection.

from their relative shafts so they may

(1) Steel inserts are provided on ends of

be assembled in the same position.

rocker arms and contact the valve bridges

Failure to correctly locate rocker

during opening and closing of the valves.

arms will cause interference of

The inserts are designed so that a

rocker arms with the fuel injection

minimum of side thrust is exerted on the

lines and will not allow centralized

valve mechanism during operation.

contact with the valve bridge

Normally, the inserts will wear very little;

assemblies.

however, if they become worn, the rocker

b. Removal.

arms must be replaced since inserts

(1) Remove the valve rocker cover.

cannot be serviced separately.

(2) Disconnect and remove fuel return

(2) Inspect rocker arm bushings for wear.

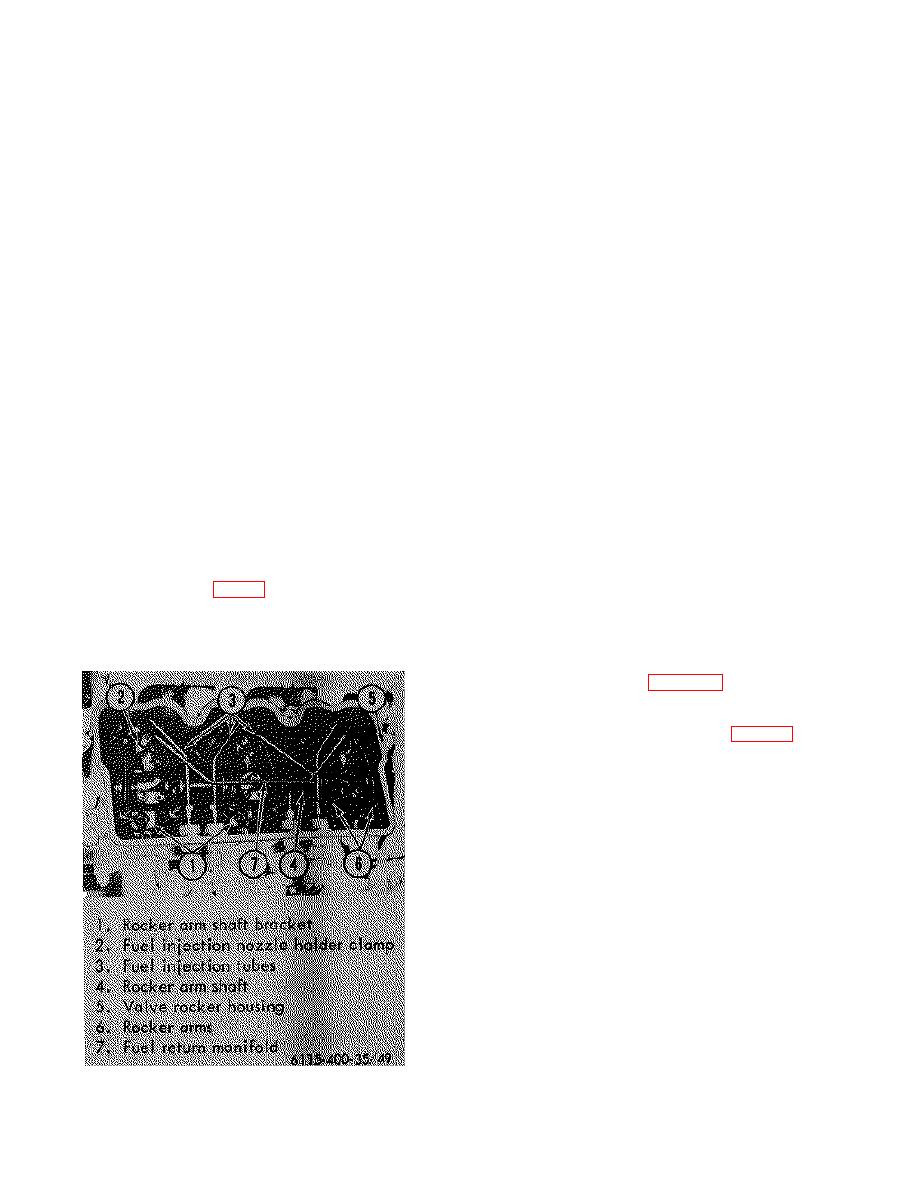

manifold (fig. 49) and fuel injection tubes.

The specified clearance between shaft

Remove the valve rocker housing if

and bushings is .001 inch-.0025 inch and

desired.

must not exceed .005 inch. If bushings

(3) Remove nuts and plain washers securing

are excessively worn, remove bushings

fuel injection nozzle holder

and install new bushings using tools as

shown in figure 50. After bushings are

installed an oil hole must be drilled in the

bushing in line with oil hole in rocker arm.

A burnishing tool (fig.

50) must be

pressed through the bushing to establish

the specified .001 inch-.0025 inch

clearance with the shaft. After burnishing,

file bushing so that it is flush with sides of

the rocker arm and remove all burrs with

a scraper.

(3) Inspect rocker arm shaft for wear and

replace if necessary. Clean oil holes in

rocker arms and rocker arm

Figure 49. Rocker arms, shafts, and brackets.

86