TM 5-6115-400-35

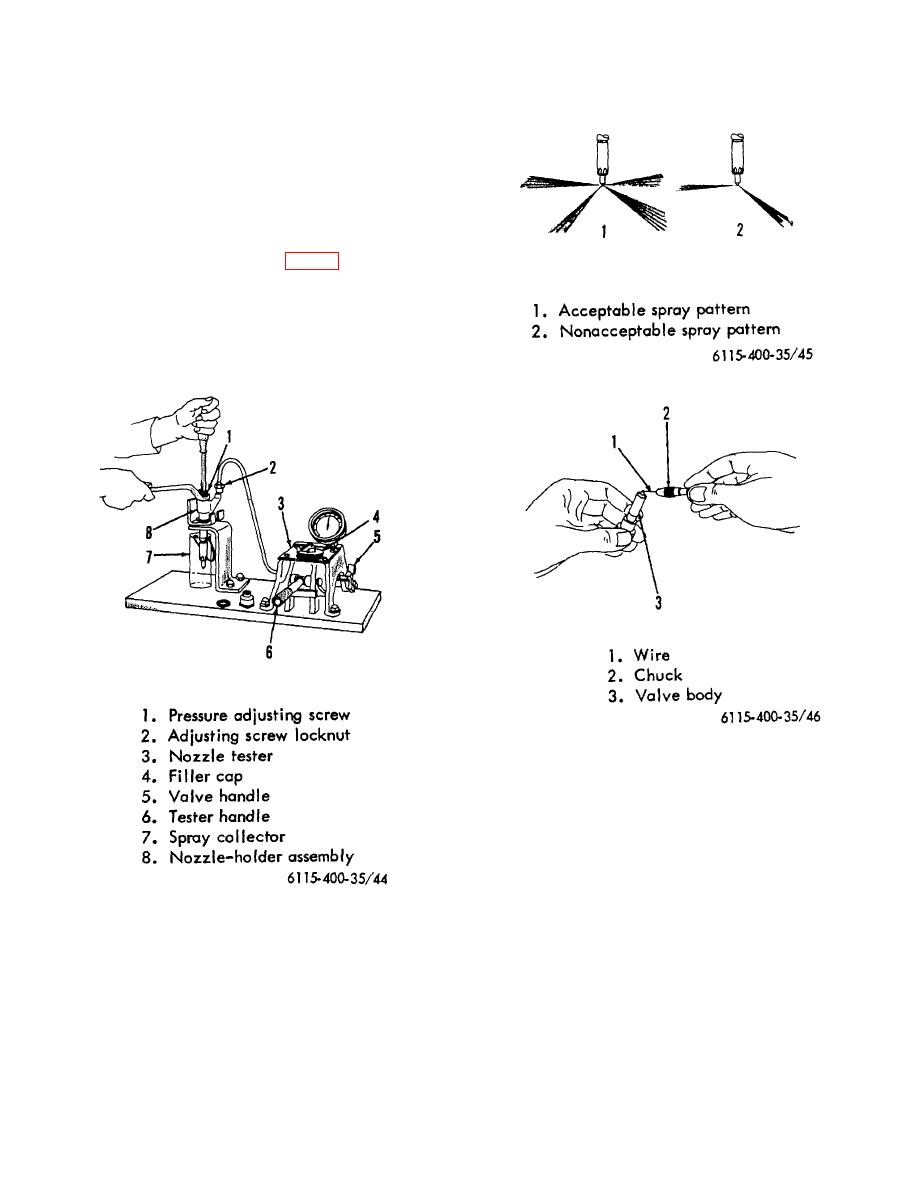

spray pattern. If fuel is being discharged

evenly through all four holes in the nozzle

tip at the specified popping pressure, the

spray pattern is considered satisfactory. If

fuel is not being discharged evenly from

all four holes in the nozzle tip, a plugged

hole or holes is indicated; then the nozzle

must be removed and cleaned, using a

.016" diameter wire (fig. 46).

e. Fuel Injection Nozzle Holder Cleaning and

Inspection.

(1) Before starting the disassembly of a fuel

injection nozzle holder, it is of the utmost

importance to have a clean work bench,

clean washing

Figure 45. Nozzle spray patterns.

Figure 46. Cleaning nozzle orifices.

fluid containers, clean tools, and clean

hands.

Cleanliness is emphasized

because injection nozzle service troubles

are, in most instances, due to dirt entering

the nozzles. Use clean paper on the work

bench and as the nozzle holder is

disassembled, place the components in a

container of clean diesel fuel as a

protection against dirt and corrosion.

Figure 44. Adjusting popping pressure.

81