TM 5-6115-400-35

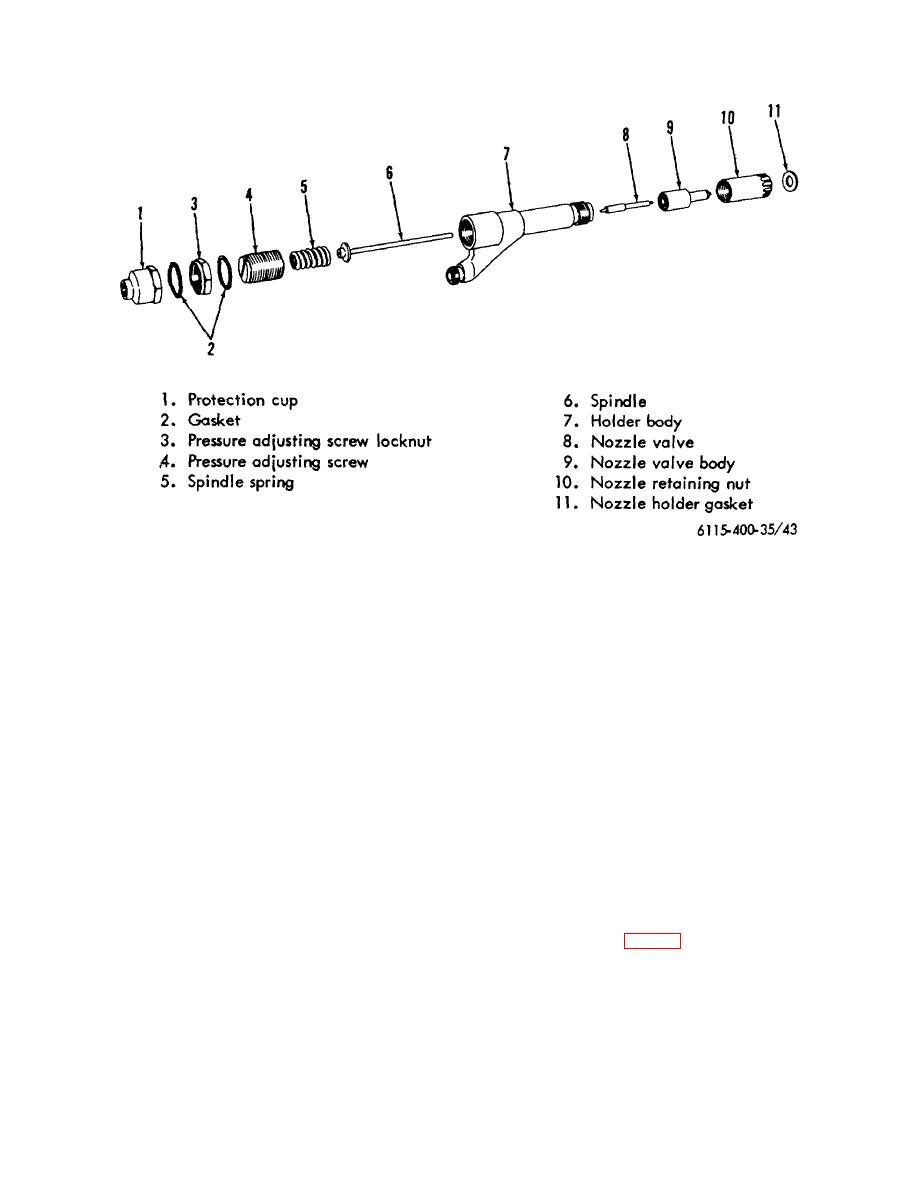

Figure 43. Fuel injection nozzle holder assembly.

(6) Dry the tip of the fuel injection nozzle.

Note

Operate the tester handle slowly until the

pressure is approximately 200 pounds

The original fuel injection nozzle-

below the popping pressure and observe

holder assemblies have the opening

the top of the nozzle for fuel leakage. If

nozzle pressure set higher at the

the nozzle does not leak or dribble, the

factory to compensate for the initial

nozzle valve is seating properly on its

set of the spindle spring.

seat in the valve body. If drops of fuel

(5) Adjust the fuel injection nozzle to obtain

collect at a pressure of approximately 200

the specified popping pressure (if

pounds or less below the popping

necessary) as follows:

pressure, the nozzle valve is not seating

(a) Remove the protection cap (1,

properly in the valve body; the valve body

fig.43) from the upper end of the

and valve must be removed for cleaning

fuel injection nozzle and loosen the

and inspection.

adjusting screw locknut (3).

(7) If the fuel injection nozzle proved

(b) While operating the tester handle,

satisfactory when subjected to the

turn the pressure adjusting screw (4)

leakage test above, operate the tester

IN to increase or OUT to decrease

handle at a speed of approximately 100

the popping pressure until the

strokes per minute and observe the

specified pressure is obtained. At

nozzle spray pattern.

this time, hold the adjusting screw

(8) The nozzle tip has four equally spaced

from turning and tighten the

holes (fig. 45). The size and spacing of

adjusting screw locknut (3).

these holes determine the

80