TM 5-6115-400-35

(j) Thoroughly rinse the valve and

valve body in clean diesel fuel or

calibrating oil. The valve must fit

freely in the valve body. To check

this fit, lift valve about one third of

its length out of the body. The

valve should slide down to its seat

without aid when assembly is held

at a 45 ngle. If the fit of the valve

a

in the valve body is unsatisfactory,

the valve may be cleaned and

polished with 1,000G lapping

compound and castor oil used on

tissue paper. The valve may be

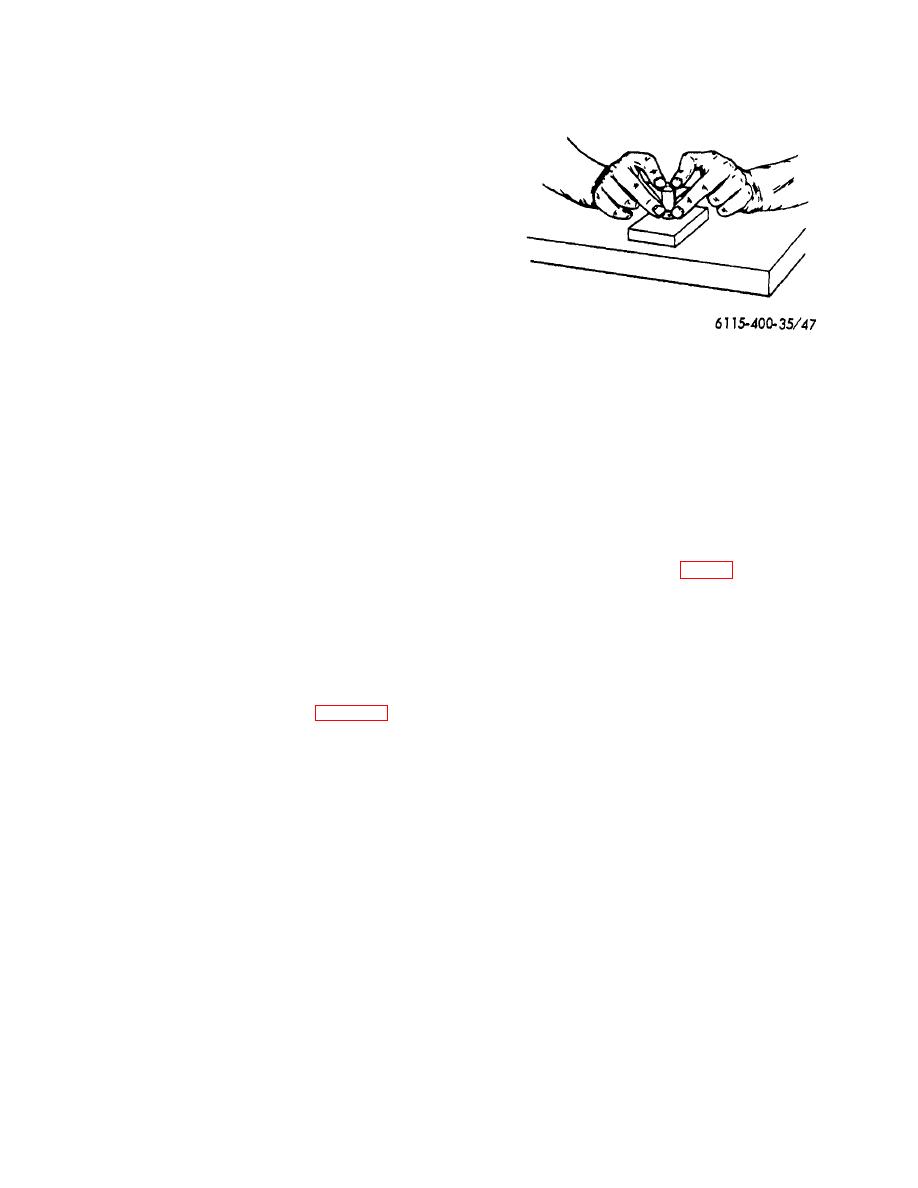

Figure 47. Lapping fuel injection nozzle valve

held by its stem in a revolving

body.

chuck for this cleaning operation.

Note

An orange stick or round toothpick

It is important that the valve body be

will be helpful in cleaning the valve.

centered in the nozzle retaining nut.

Hard or sharp tools, emery cloth,

Use care while tightening the nozzle

crocus cloth, jeweler's rouge,

retaining nut so that the valve body

grinding compounds, or other

remains centered in the nut.

abrasives should never be used in

(n) Test and adjust the fuel injection

cleaning.

nozzle.

Refer to preceding

(k) Thoroughly rinse the valve in clean

paragraph d.

diesel fuel before installing it in the

(4) Nozzle Holder Disassembly, Cleaning,

valve body.

and Assembly (fig. 43). If malfunctioning

(l) Examine the flat sealing surface of

of the fuel injection nozzle holder was not

the valve body (surface which

corrected by removal and cleaning of the

contacts lower end of the holder

nozzle

valve

body

and

valve,

body) and make certain surface is

disassemble and clean the nozzle holder

clean and free of scratches. This

as follows:

surface

may

be

lapped,

if

(a) Clamp nozzle holder assembly in a

necessary, using 1,000G lapping

copper-jawed vise and remove the

compound, castor oil, and a lapping

protection cap and gasket from

block as shown in figure 47. After

upper end of nozzle holder. Loosen

lapping, remove all traces of

and remove the pressure adjusting

lapping compound with clean diesel

screw locknut and gasket.

fuel.

(b) Remove pressure adjusting screw,

(m) Make certain that the bottom flat

spindle spring, and spindle.

sealing surface of the nozzle holder

body is clean and in good condition.

(c) Remove nozzle retaining nut,

Rinse the valve and valve body in

nozzle valve body, and nozzle

clean diesel fuel, then insert valve

valve.

into position in the valve body.

(d) Place all parts in clean diesel fuel.

Place the valve body and valve in

Using filtered compressed air, blow

position on the end of the nozzle

out the fuel passages in the holder

holder body and center the valve

body.

body with the holder body. Install

(e) Visually inspect the parts for

and tighten the nut to a torque of

damage or wear; replace necessary

60-80 ft. lbs.

parts.

Examine the flat sealing

83