TM 5-6115-584-12

NAVFAC P-8-622-12

TO-35C2-3-456-1

TM-05682C-12

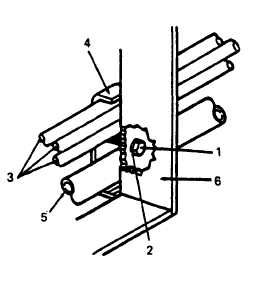

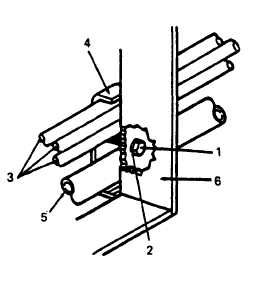

1. Screw (2)

4. Hold-down assembly (2)

2. Lockwasher (2)

5. Fuel drum adapter

3. Ground rod

6. Skid-base

Figure 3-3. Ground Rod and Fuel Drum Adapter Hold-Down

b. Cleaning and Inspection.

(1) Ground Rod. Inspect ground rod for damage and

corrosion. Pay particular attention to the threaded portions

of each piece, making certain the three pieces can be

properly assembled.

(2) Fuel Drum Adapter. Inspect adapter (5) for

cleanliness and condition of threaded portions. Clean

adapter with cleaning solvent and dry.

a. Inspect (see figure.3-5).

(3) Hold. down. Check hold-down assembly (4) for

physical damage and check condition of hardware (1

and 2).

c. Installation.

(1) Hold-down. Position lockwashers (2) on screws

(1) and insert into holes in skid-base (6). Position hold-

down assemblies (4) against skid-base (6), then start

screw (1).

Do not over-tighten screws as

hold-down assemblies may occur.

damage to

(2) Ground Rods and Fuel Drum Adapter. Slide fuel

drum adapter (5) and three piece ground rod assembly (3)

between hold-down assemblies (4) and skid base (6).

Tighten screws (1).

3-13. FUEL TANK ASSEMBLY.

a. Cleaning and Inspection (see figure 3-4).

(1) Fuel Tank Strap Assemblies. Inspect both straps

(1) for damage that would prevent them from securely

holding fuel tank (4) to skid-base (10). Check that both

straps are tight. Tighten straps by tightening nuts (2) and

washers (3) securing each strap to skid-base.

(2) Fuel Tank. Visually check fuel tank (4) for dents

or leaks. Check that filler cap (8) fits securely onto tank and

that filler cap and surrounding area is clean. Clean using

solvent and clean cloth.

(3) Fuel Level Gauge. Check fuel level gauge (6) for

physical damage. Check that gauge shows FULL when tank

is full, and EMPTY when tank is empty. Notify higher level

of maintenance for replacement of fuel level gauge.

(4) Float Switch. Inspect float switch (7) for physi-

cal damage. Check that float switch is properly attached to

tank.

(5) Fittings. Inspect three fittings (5) for physical

damage. Check that fittings are secured to fuel tank. Notify

higher level of maintenance of leaky or damaged fittings.

(6) Fuel Drain Valve. Inspect drain valve (9) for

physical damage, Check that valve operates properly. If not,

notify higher level of maintenance.

(7) Filler Cap Assembly. Inspecl filler cap (8) for

physical damage. Check that vent on underside of oap opens

and doses easily. Ensure that vent on underside of filler cap

is open before starting generator.

3-14. SHUTTER BOX ASSEMBLY.

Do not operate unit if shutter assembly is

not operating properly.

(1) Shutter Assembly. Check shutter assembly with

unit running under normal operating conditions. When

engine is cold, shutter assembly should be fully closed.

When engine warms up, shutter assembly should be fully

open at 140°F (60°C) or above at full rated load. Make

certain shutter assembly is free of dirt and oil which could

cause shutters to stick.

3-10

Change 7