TM 5-6115-584-12

NAVFAC P-8-622-12

TO-35C2-3-456-1

TM-05682C-12

B-Before

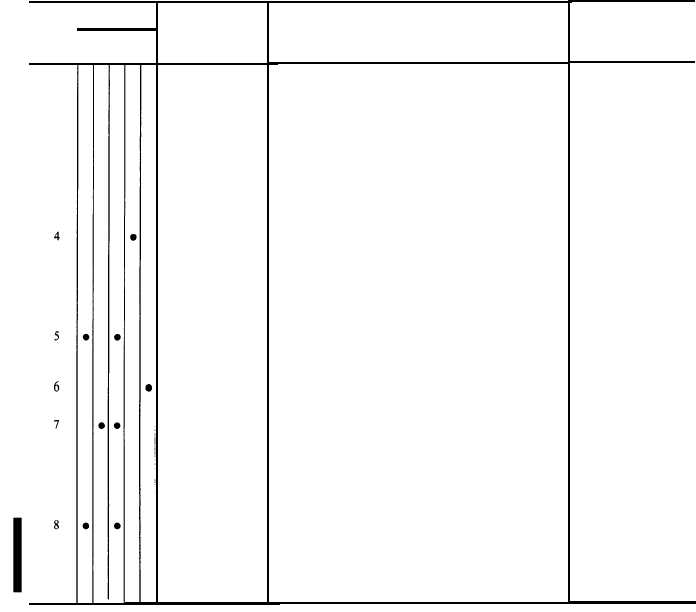

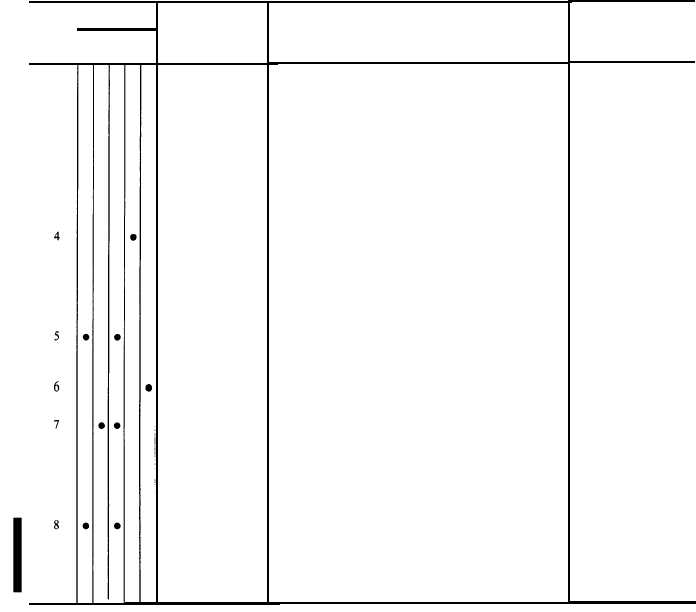

Table 3-2. Operator/Crew Preventive Maintenance Checks and Services (Cont.)

NOTE

Within designated interval, these checks are to be performed in the order listed.

Item

No.

Interval

D-During

A-After

W-Weekly

M-Monthly

Item To Be

Inspected

Batteries

Fuel strainer

and filters

Fuel tank

Acoustical

Suppression Kit

(ASK)

Front Panel

Assembly

Day Tank

Procedures

Check for and have repaired

or adjusted as necessary

NOTE

If the Generator Set is not going to be operated for

two weeks or more, disconnect the negative cable

from the battery. The Generator Set will be ready to

go upon reconnection of the negative cable.

Even if the Generator Set is operated every day, the

battery may still run down. A run down battery does

not have time to be recharged. Run the Generator Set

for at least 30 minutes at rated speed. Allow extra

running time if the preheater was used, or if starting

took several tries.

Check battery electrolyte levels. Proper level is 3/8

inch above plates. Use clean water (distilled if avail-

able).

NOTE

Fuel system temperature must be above freezing

when draining water and sediment.

Drain water and sediment from strainer, primary and

secondary filters. Allow to drain until fuel runs clean

(para 3-20).

Drain water and sediment. Allow to drain until fuel

runs clean (para 3-13).

Make a visual inspection of the ASK for loose or miss-

ing hardware, and for any bent, cracked or broken

parts. Tighten all loose hardware.

Ensure that front panel assembly is free from obstruc-

tions or accumulation of dirt, leaves, debris which

would hinder air flow.

Drain water and sediment.

NOTE

In freezing weather drain shortly after operation.

A11ow to drain until fuel runs clear.

Section IV. TROUBLESHOOTING

Equipment is

Not Ready/

Available if:

3-10. MALFUNCTIONS NOT CORRECTED BY USE

OF THE TROUBLESHOOTING TABLE.

3-9. GENERAL

This section contains troubleshooting information for locat-

ing and correcting operating troubles which may develop in

This manual cannot list all malfunctions that may occur nor

the Generator Set. Each malfunction for an individual com-

all test or inspections and corrective actions. If a malfunc-

ponent, unit, or system is followed by a list of tests or inspec-

tion is not listed or cannot be corrected by listed corrective

tions which will help you to determine probable causes and

actions, notify your supervisor.

corrective actions to take. You should perform the test/

inspections and corrective actions in the order listed.

3-6

Change 9