TM 5-6115-584-12

NAVFAC P-8-622-12

TO-35C2-3-456-1

TM-05682C-12

Section III. PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

3-4. GENERAL.

To ensure that the Generator Set is ready for operation at

all times it must be inspected systematically, so that de-

fects may be discovered and corrected before they result in

serious damage or failure. The necessary preventive main-

tenance checks and services that are to be performed by the

Operator personnel are listed and described in paragraph 3-8.

3-5. CORRECTING AND REPORTING DEFICIENCIES.

Defects discovered during operation will be noted for future

correction. Stop operation immediately if a deficiency is

noted which would damage the equipment or is a safety

hazard. All deficiencies and short comings will be recorded

together with the corrective actions taken on the applicable

form. Marine Corps users should refer to current issue of

TM 4700-15/1.

3-6. DETERMINING PMCS INTERVALS.

Certain Operator PMCS on this unit should be performed

on a - per hours of operation - basis. The running time

meter on the control panel should be used to determine the

Generator Set operating time.

3-7. PMCS FOR UNITS IN CONTINUOUS OPERATION.

For PMCS performed on an operating time basis, perform

PMCS as close as possible to the time intervals indicated.

For units in continuous operation, perform PMCS before

starting operation if continuous operation will extend

service interval past that which is shown.

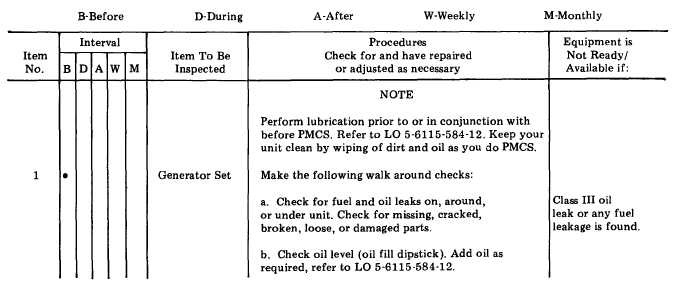

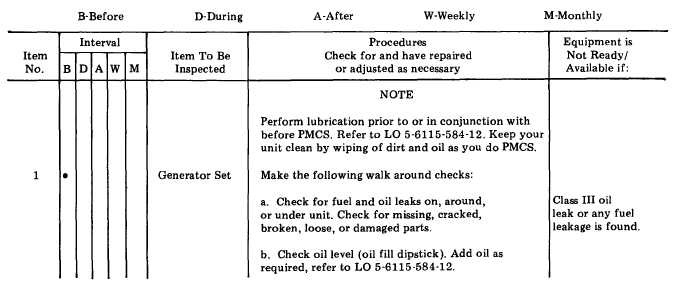

3-8. PREVENTIVE MAINTENANCE CHECKS AND

SERVICES.

Table 3-2 contains a tabulated listing of PMCS which shall

be performed by the Operator personnel. The item numbers

are listed consecutively and indicate the sequence of

minimum requirements.

NOTE

Leakage

definitions for operator/crew PMCS

shall be classified as follows:

Class I

Class II

Class III

Seepage of fluid (as indicated by wetness or dis-

coloration) not great enough to form drops.

Leakage of fluid great enough to form drops

but not enough to cause drops to drip from item

being checked/inspected.

Leakage of fluid great enough to form drops that

fall from the item-being checked/inspected.

Equipment operation is allowable with minor

leakages (Class I or II). Of course, you must

consider the fluid capacity in the item/system

being checked/inspected. When in doubt, notify

your supervisor.

When operating with Class I or Class II leaks,

continue to check fluid levels as required.

Table 3-2. Operator/Crew Preventive Maintenance Checks and Services

NOTE

Within designated interval, these checks are to be performed in the order listed.

3-4

Change 5