T M 5 - 6 1 1 5 - 5 8 4 - 12

N A V F A C P - 8 - 6 2 2 - 12

T O - 3 5 C 2 - 3 - 4 5 6 - 1

TM-05682C-12

On ASK equppied

4-31. LOW OIL PRESSURE SWITCH.

generators, remove oil access door.

a. Test on Equipment (see figure 4-30). Disconnect

leads from terminals 1 and 2. With master switch in off

position, use ohmmeter to check for continuity between

terminals 1 and 2 of switch. If continuity is indicated,

replace switch. Connect leads to switch terminals 1 and

2.

b. Removal. Disconnect leads from terminals 1 and 2.

Use wrench on square portion at base of switch (11) and

remove from adapter (5).

c. Bench Test. Connect switch to a controllable supp-

ly of dry compressed air. Connect ohmmeter across ter-

minals 1 and 2 and slowly apply compressed air. Switch

should close (continuity) when 14 ± 2 psi of compressed

air is applied.

4-34

Change 7

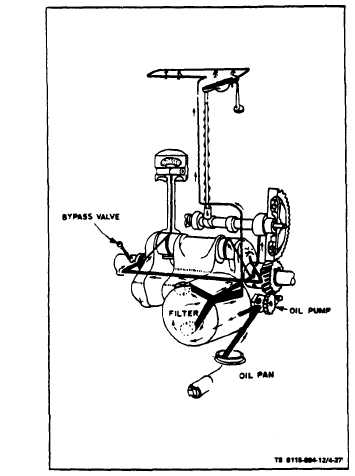

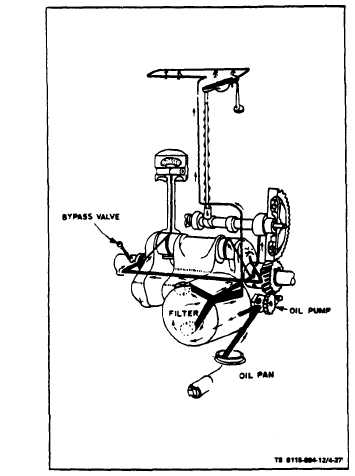

Figure 4-27. Pressure Oil System

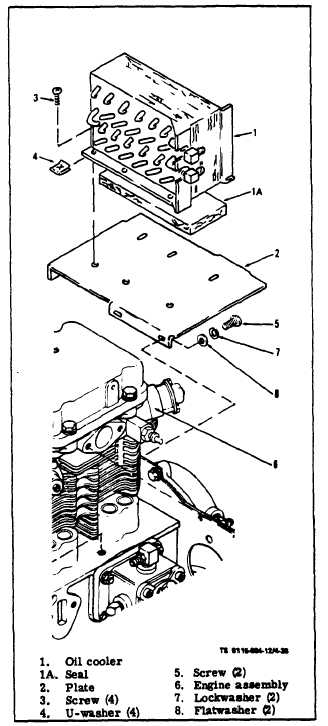

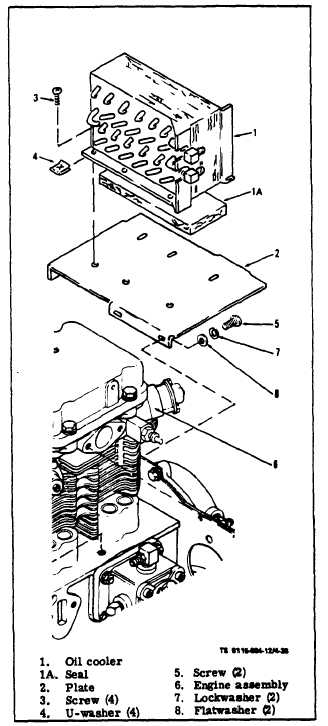

Figure 4-28. Oil Cooler Assembly