TM 5-6115-584-12

NAVPAC P-8-622-12

TO-35C2-3-456-1

TM-05682C-12

(20) and spring (12). Slide gear (5) out through

opening in engine back plate. Clean any gasket (13)

material from switch and back plate.

d. Repair. Repair starter lockout switch by re-

placing parts found to be defective under inspection

e. Replace. Make certain spacer (16) is on shaft

and slip timing gear (5) through opening in engine

back plate. Make certain that shaft seats properly in

gear cover and that gear teeth are properly meshed.

Place thrust plunger (20) and spring (12) in gear

shaft. Slide switch and gasket (13) over shaft and

attach to engine back plate with two screws (9) and

Iockwashers (10). Use a new gasket (13) between

switch and engine back plate. Reconnect electrical

connector (8).

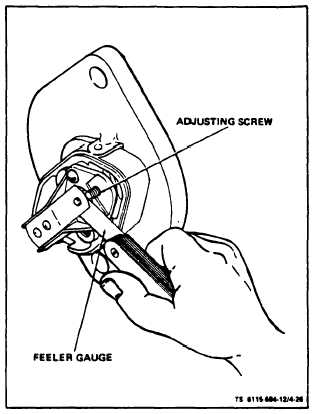

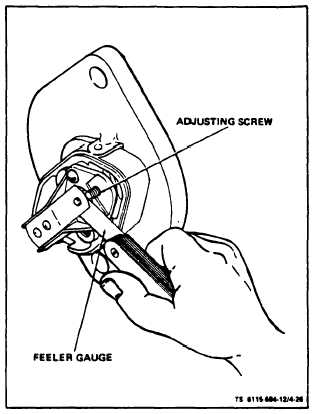

f. Adjust. With engine stopped, remove cover re-

taining wing nut (1) and remove cover (3). Turn

adjusting screw (14) clockwise until points open.

Turn adjusting screw counterclockwise until points

just ClOSe (see figure 4-26). Start engine and dis-

connect switch from wiring harness at connector (8,

figure 4-25). Adjust adjusting screw for a 0.040 point

gap. Replace cover (3) and wing nut (1). Reconnect

connector (8).

Be sure two wires are recessed in slot of

housing before tightening cover down.

Section XI.

4-29. FUNCTION AND DESCRIPTION

The diesel engine has pressure Iubrication to all

working parts (see figure 4-27). The oil system

includes oil intake cup, gear type oil pump, bypass

valve, oil pressure gauge, low oil pressure shutoff,

full-flow oil filter, oil coder, and passages to de-

liver oil throughout the engine. Oil is held in the oil

base, and forced through the oil filter and oil cooler

by the pump. Lines leading to the rocker housing,

passages through the block to crankshaft and front

camshaft bearing, crankshaft passages to connecting

rod bearings and connecting rod passages to piston

pin bushings complete the oil system network The

bypass valve controls oil pressure by allowtng excess

oil to flow directly back to the crankcase.

4-30. OIL COOLER

a. Inspect (see figure 4-28). On ASK equipped generators,

remove ASK cover assembly (para 5-3). Inspect oil cooler (1)

for physical damage. Visually check for leaks where oil cooler

is connected to oil hoses (figure 4-29). Check that cooler Is

securely fastened to mounting plate (2, figure 4-28) and that

plate is securely fastened to engine. Inspect all hoses for

Figure 4-26. Adjusting Starter Lockout Switch

MAINTENANCE OF OIL SYSTEM

leaks and physical damage. Inspect seal (1A, figure 4-28)

and replace if damaged. Blower housing must be removed

to inspect cooler and hoses.

b. Service. Every 500 operating hours clean oil

cooler fins with air gun (50 psi) held 12 inches away

from the fins. Every 2500 operating hours remove

oil cooler and flush in both directions using solvent

at 25 psi.

c. Remove. Remove blower housing. Disconnect oil

cooler hoses at valve of oil filter adapter (see figure

4-29), Drain cooler into suitable container. Remove

four machine screws (3, figure 4-26) and special U-

shaped washers (4) attaching oil cooler (1) and oil

cooler seal (1A) to mounting plate (2) and remove

cooler (1).

Remove and check hoses. Plug hose

if not used immediately.

d. Replace. Install oil cooler (1) and oil cooler seal (1A) on

mounting plate (2) and secure with screws (3) and special

U-shaped washers (4), Attach oil hoses to cooler as shown in

figure 4-29. Replace blower housing shown in figure 4-29.

Replace blower housing, Replace any oil lost. On ASK equipped

generators, replace ASK cover assembly (para 5-3).

Change 7

4-33