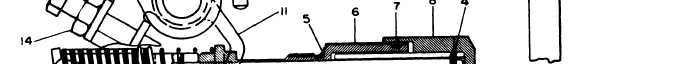

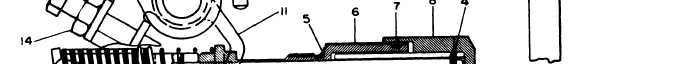

ME 6115-545-34/14-24

Figure 14-24. Variable speed droop adjustment

14-48. Fuel Injection Pump, Bench Test.

a. The following bench test procedure is based on

the following conditions.

(1) Injection lines.

Two standard line sizes;

1/16 inch I. D, by 20 riches and 3/32 inch I.D. by 20

inches long.

(2) Fuel. The readings are based on fuel with a

viscosity of 34-36 SSU at 100° F.

(3) Fuel Temperature. 110-115° F.

(4) Nozzles: part number 12SD12 adjusted to an

opening pressure of 2500 psi (175 ATS).

b. Use diesel injector pump test stand and pro-

ceed as follows

(1) Mount the pump securely with a suitable

adapter. A drive adapter, usually with a ball bear-

ing, supports the shaft.

This pump must be tested

using an intermediate support bearing. Install high

pressure injection lines using new gaskets. Leave

fuel line connector screws at pump and injection

line nuts at nozzles loose. Install inlet and return

lines and transfer pump pressure gauge. Use a re-

striction fitting on the return line. The pump comes

with one installed.

(2) Set counter and tachometer switches to

clockwise position.

Remember that the test stand

tachometer registers pump speed.

14-53