coil.

This can result in questionable

operation and rejection of good coils

under some conditions. Do not attempt

to check solenoid operation with the

cover removed from the pump. The

governor linkage spring aids operation

when the cover is assembled.

g. Reassemble solenoid.

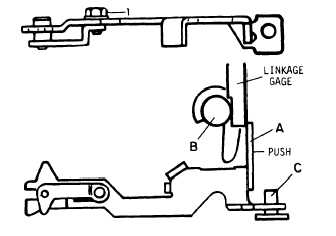

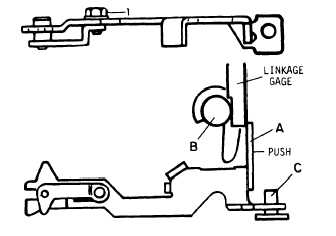

ME 6115-545-34/14-22

Figure 14-22.

ThrottIe Linkage Adjustment

of the contact screws. Check the solenoid for a com-

plete circuit with an ohmmeter.

e. Assemble the shut-off arm (15) and spring (13)

and guide (14) to the coil. Before installation of the

solenoid assembly to the cover is made, adjustment of

the arm travel and spring tension should be carried

out as illustrated in figure 14-23. Install new insulating

tubes (11, 12) to both contact screws. Insert the assem-

bly into the governor control cover as a unit. Replace

the insulating washer (10) and assemble the contact

nuts (7,8) (20-25 inch-pounds). Mount the cover assem-

bly, with new cover seal (6), to the pump and tighten

securely.

f. With the pump mounted on the test bench, the

electrical shut-off device must be checked with 24 Vdc

and wide open throttle at the following speeds:

(1) 400 rpm

(2) Full load governed speed

(3) High idle (shut-off only)

NOTE

If use of automotive type batteries is im-

practical, a good, heavy duty battery

charger can be used as long as voltage can

be selected and will hold with minimum

drop (1/2 volt max. ) during application to

the solenoid coil.

Use of small, inexpen-

sive trickle chargers is not recommended,

since a voltage drop of 2-3 volts can be

expected when current is applied to the

h. Install solenoid on fuel injection pump.

—

i. On equipment test.

Energize solenoid with

24 Vdc. If a clicking sound is heard, then the sole-

noid is operating.

14-47. Variable Speed Droop Device.

a. Remove the cover, shut-off cam, shut-off

shaft assembly, throttle shaft assembly, throttle

shaft lever, and governor linkage hook. Remove end

plate assembly.

b. Remove the adjusting cap (8, fig. 14-24) by

pulling to the rear of the pump. With a pair of needle-

nose pliers, remove the control rod clip (4). Do not

bend the control rod. Loosen and remove the control

rod guide (6), “O” ring (5) and guide washer (1 5).

Disengage the governor spring (2) from the governor

arm (1) and remove the governor spring and control

rod assembly as a unit.

c. Examine the governor spring for distortion and

the–spring guide and bushing for excessive wear.

Replace the two seals on the control rod guide.

Check control rod for straightness and replace, if

needed.

d. Insert the control rod assembly (3) through the

threaded hole from the inside of the housing. Slide

the control rod guide (6), O ring (5) and guide (9) over

the end of the control rod (3), and thread into hous-

ing. Tighten securely. Insert clip (4) into the con-

trol rod end being careful not to bend the rod. Slide

the adjusting cap (8) over the new seal on guide (6).

Thread five full turns of governor spring (2) onto the

spring guide (9) with the spring guide and bushing (10)

against each other as shown in figure 14-24. Slip the

free end of the governor spring over the formed ends

of the governor arm (1) with the bent end of spring

between the two tabs.

e. Install the end plate, throttle shaft assembly,

throttle shaft lever, shut-off shaft assembly, and

shut-off cam. Adjust low idle adjusting screw so

bushing (10) just touches rod guide and forked end of

throttle shaft lever straddles and engages flats on

bushing. Replace cover.

The speed droop assembly

is now positioned for minimum droop.

f. During bench test, make normal check of out-

put, metering and transfer pump pressure at full load

governed speed as called for in paragraph 14-48. High

idle adjusting screw should be backed all the way out

and throttle held open as far as possible. Refer to par-

agraph 14-48 for bench test of fuel injection pump. See

figure 14-24 while making adjustments an speed droop.

14-51