T O 35C2-3-442-2

P-8-627-34

TM-07464A-35

TM 5-6115-457-34

6-118. 400 HERTZ ELECTRONIC

b. Removal. Refer to figure 6-22 and

COMPONENTS ASSEMBLY (A6) .

tag, then disconnect wiring to the permis-

sive paralleling relay. Remove the four

6-119. ON EQUIPMENT TEST.

screws securing the relay in position.

a. Symptom and Isolation of Malfunction.

6-116. BENCH TEST.

A malfunction of the electronic component

assembly (A6) usually is indicated by an un-

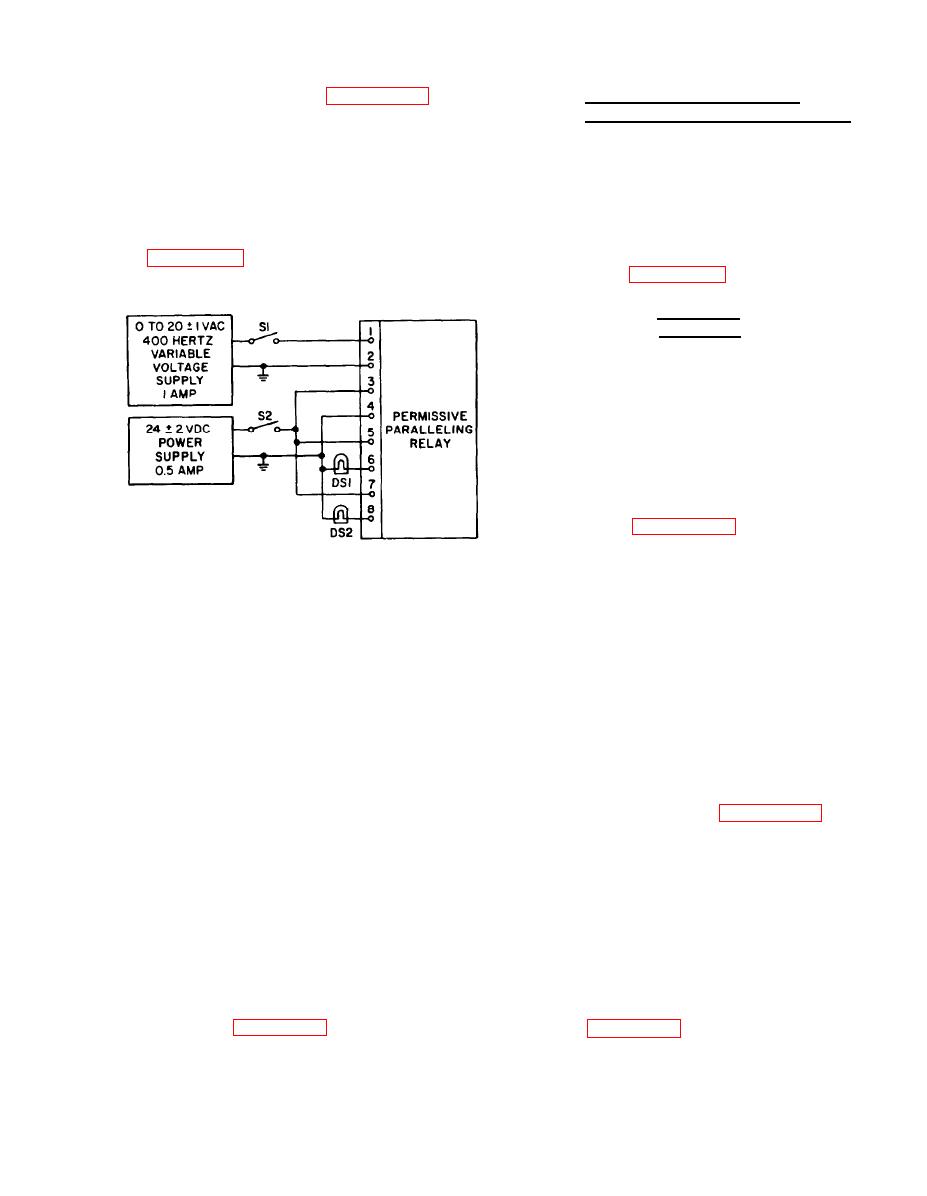

a. Connect the permissive paralleling

stable generator frequency or by loss of

relay to the test equipment as illustrated

frequency control. To isolate this malfunc-

in figure 6-30.

tion, refer to figure 1-16 and proceed as

follows :

WARNING

Exercise extreme care not to touch

exposed electrical connections when

working inside mode II relay box

with generator set operating.

NOTE

Remove cover from mode II relay

box to gain access to the test

points, see figures 6-15 and 6-22.

1. To check for cause of unstable

Figure 6-30. Permissive Paralleling

set to the R x 10,000 scale, to capacitor

C1. The meter should indicate 0 resistance

relay (K16) test set up

and slowly rise to infinite resistance. If

capacitor C1 does not meet the above re-

quirements, the capacitor is defective.

b. With switches S1 and S2 open, energize

variable voltage supply and adjust to 15 VAC.

Close switches S1 and S2. Indicator DS1

2. To check for lack of frequency

should energize and DS2 should de-energize.

control, measure the resistance of resisters

R4 and R5. The resistance should be 249

c. Decrease voltage of variable voltage

ohms 1 percent, if not, the resistors are

supply until indicator DS1 de-energizes. The

defective.

voltage should be 8 1 VAC.

b. Removal. Refer to figure 6-22 and

d. If the permissive paralleling relay does

tag, then disconnect wiring to the electronic

not meet the requirements of the above tests,

components assembly. Remove the three

replace the relay.

screw assemblies securing the assembly in

position.

e. Remove the permissive paralleling

relay from the test equipment.

6-120. BENCH TEST.

6-117. INSTALLATION. Refer to figure

6-22 and install the permissive paralleling

relay in the mode II relay box. Secure the

Using an ohmmeter test the elec-

relay in position with four screw assemblies,

tronic components assembly for values as

then refer to figure 1-17 and reconnect

noted in figure 6-31.

wiring. Replace mode II relay box cover.

Change 8

6-87