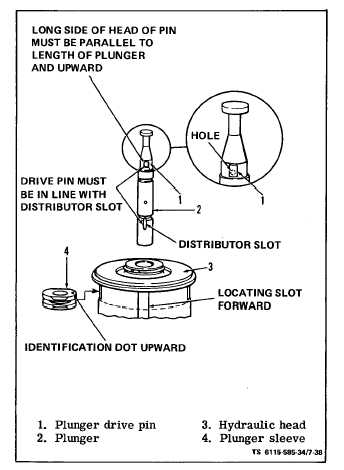

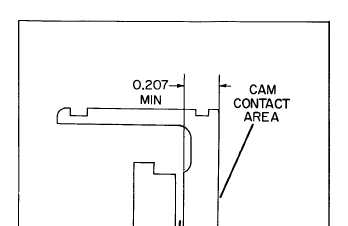

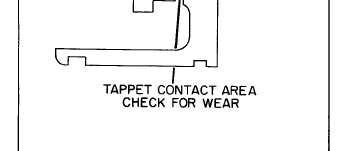

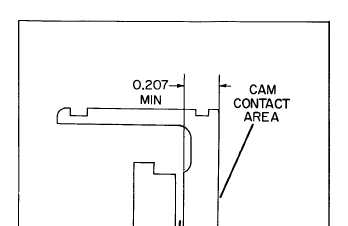

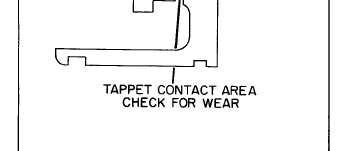

Figure 7-37. Inspecting Tappet

(5) Inspect the tappet (20) for possible wear at

the contact areas. The primary contact areas are the

tappet contact area and the cam contact area (figure

7-37). Replace the tappet if wear indentations exceed

0.002’. The tappet thickness measured between the

plunger button contact surface and the cam contact

area must be 0.207” or larger.

(6) The pump housing (6, figure 7-34) should be

washed in a cleaning solvent. Check all the screw

threads in the housing, damaged threads can be re-

paired using thread inserts.

(7) Examine the pump housing for cracks or

other damage which will cause oil leakage. Replace

cracked housings.

NOTE

The control unit assembly is serviceable as a

unit only. Each control unit assembly is fur-

nished with a factory fitted plunger sleeve pin.

(8) Holding sleeve of control unit assembly (4),

rotate lever; shaft must turn freely. If a binding

condition exists, wash assembly in a cleaning agent,

and repeat procedure. If binding condition is still

present, control unit assembly must be replaced. Also

check to make certain that weld holding lever to shaft

is intact.

(9) The flat end of plunger sleeve pin (5) must be

checked for clearance in the mating slot of the

plunger sleeve. If the clearance is greater than 0.0015”,

the entire control unit must be replaced.

TM5-6115-585-34

NAVFAC P-8-262-12

TO-35C2-3-455-2

TM-05684C-34

(10) Plunger sleeve pin (5) must fit snug but must

be free to rotate in control unit assembly.

NOTE

New part clearance is 0.0002-0.00081". If

clearance exceeds 0.0015”, replace control

unit assembly.

d. Reassembly (see figure 7-34).

NOTE

Replace all copper and “O" ring gaskets.

(1) After all parts have been thoroughly cleaned

and inspected and after all worn units have been re-

placed, dip the individual parts in clean fuel oil.

(2) Invert the hydraulic head (17) and place it on

a clean bench so that the head locating slot is forward.

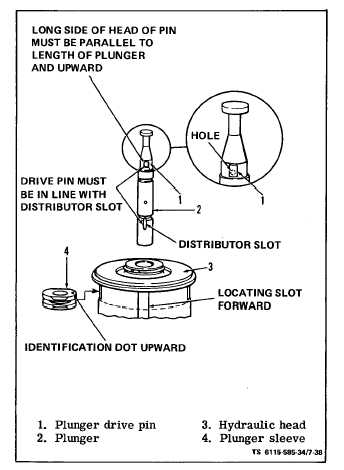

(3) Refer to figure 7-38 and align the plunger

drive pin (1) into the plunger (2) so that the head of

the plunger drive pin is in the line with the distribu-

tor slot. Turn the plunger drive pin until its long side

is parallel to the length of the plunger with long end

up.

Figure 7-38. Assembling Hydraulic Head

7-35