TM5-6115-585-34

NAVFAC P-8-262-12

TO-35C2-3-455-2

TM-05684C-34

1. Retaining plate screw (2)

14. Copper gasket

27. Spring ring

2. Tab washer (2)

15. Head retaining screws (4)

28. Face gear

3. Control unit retaining plate

16. Head retaining clamps (4)

29. Thrust washer

and stop assembly

17. Head assembly

30. Plunger drive pin

4. Control unit assembly

18. Head"O" ring

31. Timing screw

5. Plunger sleeve pin

19. Head “O” ring

32. Gasket

6. Pump housing

20. Tappet

7. Cap nut

33. “O” ring

21. “O” ring

34. Plunger sleeve

8. Gasket

22. Button spring ring

35. Plunger

9. Delivery valve holder

23. Plunger button

36. Control unit bore

10. Valve spring

24. Lower spring seat washer

37. Pin

11. Delivery valve assembly

25. Seat

38. Flatwasher

12. Valve spacer

26. Plunger spring

39. Lockwasher

13. Locating screw

40. Nut

TS 6115-585-34/7-34(2)

Figure 7-34. Disassembly of Fuel Injection Pump (Sheet 2 of 2)

(7) Remove the hydraulic head locating screw (13)

and copper gasket (14).

(8) Remove the four head retaining screws (15)

and the four head retaining clamps (16). Carefully

rest tappet on clean surface and using shaft head,

hammer pump body assembly until hydraulic head

assembly separates from body assembly.

(9) Remove the “O” rings (18 and 19) from the

hydraulic head and the pump housing.

(10) Remove the tappet (20) and related “O” ring

(21) from the face gear bore.

(11) Remove the spring ring (22) and the plunger

button (23) from the end of the plunger (the plunger is

part of hydraulic head assembly).

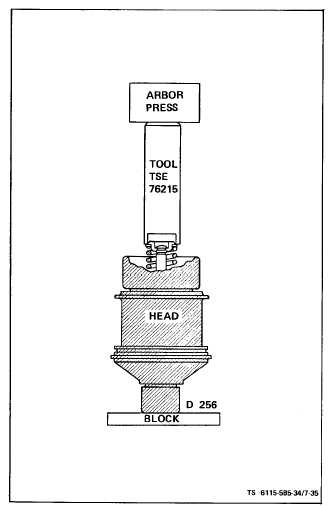

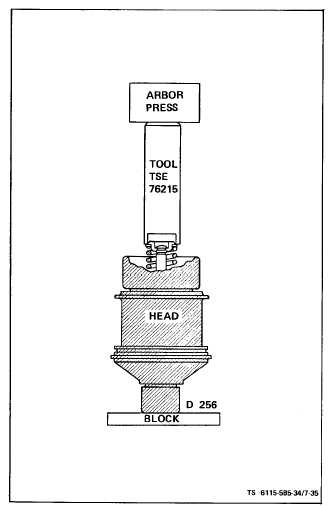

(12) Invert the hydraulic head assembly and place

it in a suitable arbor press (see figure 7-35).

(13) Position tool TSE 76215 over the lower spring

seat washer (24, figure 7-34) and depress the plunger

spring, then remove the lower seat (25).

(14) Remove lower spring seat washer (24, figure

7-34) and plunger spring (26).

(15) Place the hydraulic head assembly on a

bench. Using two screwdrivers to carefully pry off

the face gear (28), then remove the thrust washer (29).

(16) Do not remove the plunger (35) out of the

hydraulic head.

NOTE

The Plunger, Plunger Sleeve and Hydraulic

Head are mated Parts and must ALWAYS be

kept together.

c. Inspect (see figure 7-34).

(1) Place the delivery valve assembly in test

fixture TSE 76226 and secure in a suitable vise (see

figure 7-36).

Figure 7-35. Removing Lower Spring Seat

7-33