TM5-6115-585-34

NAVFAC P-8-262-12

TO-35C2-3-455-2

TM-05684C-34

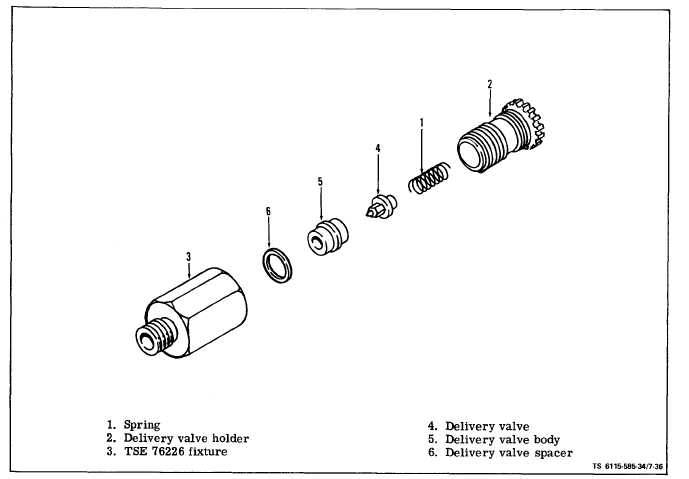

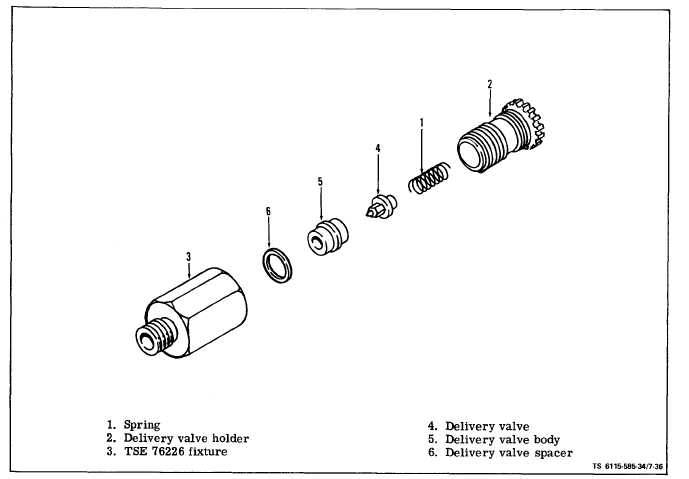

Figure 7-36. Delivery Valve Test Assembly

(a) Insert the delivery valve spring (1) and the

delivery valve holder (2). Tighten the delivery valve

holder to a torque of 70-75 ft-lbs. Figure 7-36 illus-

trates the components that are to be assembled to

test fixture TSE 76226 (3).

(b) Attach test fixture TSE 76226 (3) to a manual-

ly operated Nozzle Test Stand.

NOTE

Always check to make certain that all external

connections are tight and that the Nozzle Test

Stand is in good order.

(c) Delivery valve opening pressure is 300-600

psi. Delivery valve must hold 275 psi for 30 seconds.

Remove delivery valve assembly from test fixture.

The delivery valve spring (1) must be free of nicks or

wear (flat spots). Always replace nicked or worn

springs.

7-34

LAPPING COMPOUND MUST NOT COME IN

CONTACT WITH THE RELIEF PISTON DUR-

ING THE LAPPING OPERATION, AND ALL

LAPPING COMPOUND MUST BE REMOVED

BEFORE

INSTALLING THE DELIVERY

VALVE ASSEMBLY INTO THE HYDRAULIC

HEAD.

(d) If the delivery valve assembly is leaky,

the delivery valve seat may be lapped to its corres-

ponding seat in the delivery valve body with a small

quantity of suitable Lapping ‘Compound.

(2) If the plunger button (23, figure 7-34) is

grooved, ridged, scored, or exhibits an uneven wear

pattern, it must be replaced.

(3) Install a thrust washer (29). Replace thrust

washer if damaged.

(4) Replace the plunger drive gear (28) if the

teeth are worn or damaged.