TM5-6115-585-34

NAVFAC P-8-623-34

TO-35C2-3-455-2

TM-05684C-34

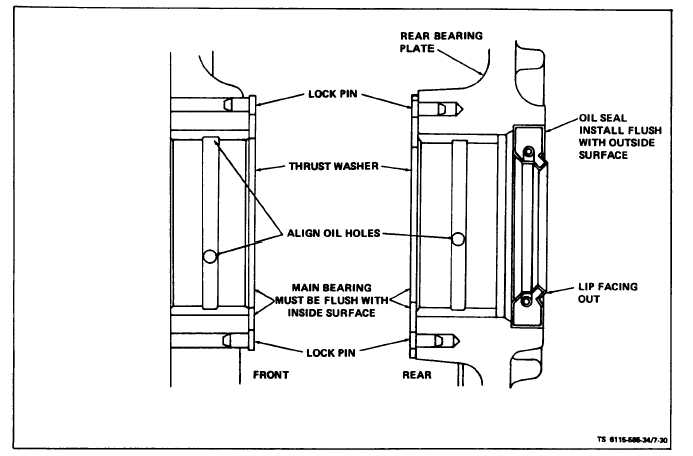

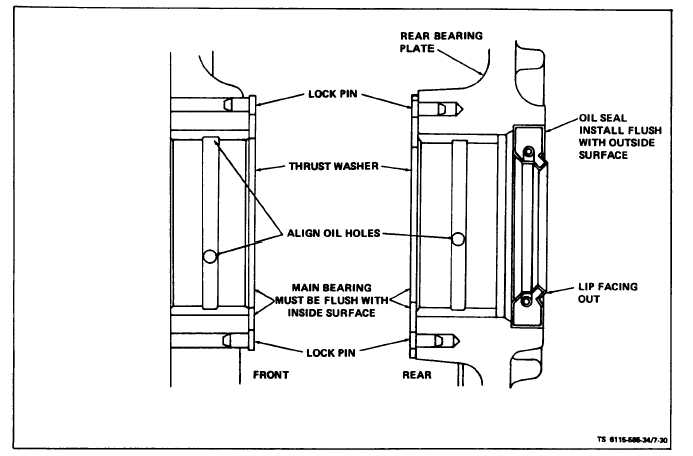

Figure 7-30. Crankshaft Bearing Installation

during installation. Mount and secure rear bearing

plate (19).

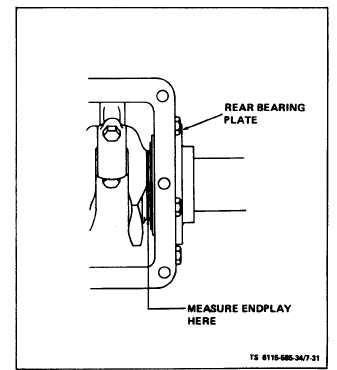

(7) Check crankshaft end play (see figure 7-31).

Use enough rear bearing plate shims to provide 0.010

to 0.015 inch end play. If more than 0.010 inch total

thickness is required then use a steel shim of proper

thickness and an 0.005 inch thick gasket on each side

of shim. This avoids excessive gasket compression

and maintains bolt torque. Shims are available in

0.005, 0.010, 0.015, and 0.020 thickness.

(8) Install keys (26, figure 7-15) on crankshaft

(33), then drive gear (17) into place using fabricated

tool (see table 2-2). Install retaining washer (16) and

lock ring (15).

(9) Refer to paragraph 7-10 and install rod and

piston assemblies.

(10) Refer to paragraph 7-4 and 7-5 and install

flywheel and housing.

(11) Refer to paragraph 7-11 and install oil pump

cup assembly.

(12) Refer to paragraph 7-10 and install oil base.

(13) Refer to paragraph 7-14 and install gear

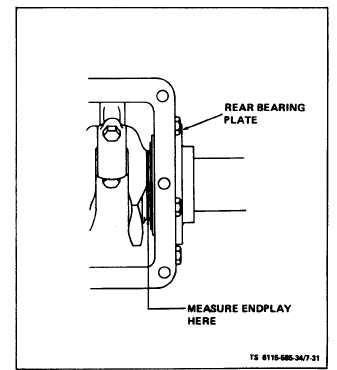

Figure 7-31. Crankshaft End Play Measurement

cover.

7-29