TM5-6115-585-34

NAVFAC P-8-262-12

TO-35C2-3-455-2

TM-05684C-34

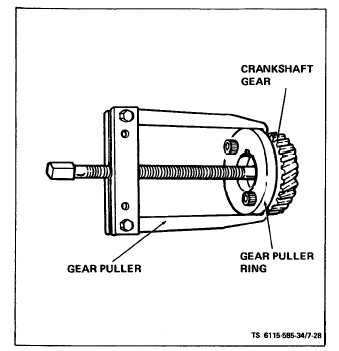

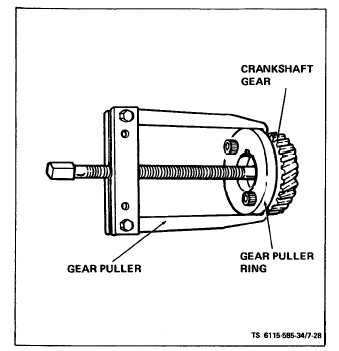

Figure 7-28. Crankshaft Gear Removal

(14) Remove center main bearing housing (29)

and center bearings (31 and 32) and remove crank-

shaft (33) through rear opening in crankcase.

b. Clean and Inspect.

(1) Crankshaft. Clean crankshaft and blowout all

oil passages. Check journals for out-of-round, taper,

grooving or ridges. Pay particular attention to ridges

or grooves on either side of oil hole areas. Unusual

conditions here often point to previous neglect of oil

changes. If journal dimensions are not within limits

or journals are scored, metallize and regrind crank-

shaft to standards.

(2) Bearings. Replace bearings if clearances are

greater than limits (see table 1-2), or if bearings are

worn, grooved or broken.

(3) Rear Oil Seal. Inspect seal for wear or dam-

age which might cause it to leak.

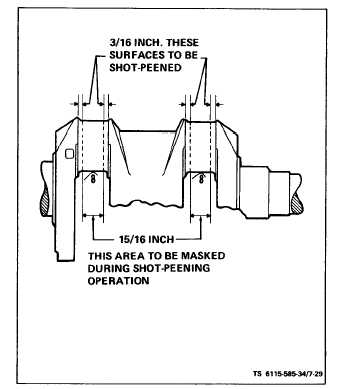

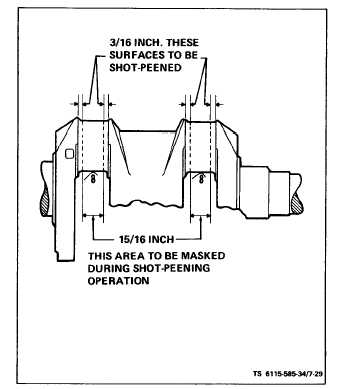

c. Rebuild Crankshaft. If crankshaft requires re-

grinding, metallize and regrind to standards. Special

procedures must be observed when reworking diesel

crankshafts. In addition to regrinding, the crankshaft

must be shot -peened and super-finished. Failure to

shot-peen the crankpin fillets is likely to cause early

failure. When the shaft is reground, follow this data

and figure 7-29 to shot-peen each crankpin fillet.

(1) Almen gauge reading, 0.012-A.

(2) Peen with 0.019 inch diameter cast steel shot.

(3) Peen for 30-seconds on each crankpin fillet.

7-28

Figure 7-29. Crankshaft Peening

(4) Mask off connecting rod bearing areas.

d. Installation.

NOTE

After each installation step, check crankshaft

to be sure it is not frozen in place.

(1) Heat cylinder block (34, figure 7-15) and bear-

ing plate (19) at 325° F (163° C) in an oven 30 minutes

and press front and rear main bearings (22) into place,

aligning bearing housing oil holes (see figure 7-30).

(2) Install thrust washers (25, figure 7-15) on

locking pins (see figure 7-30).

(3) Oil bearing surfaces and install crankshaft

(33, figure 7-15) from rear of crankcase, through

rear bearing plate hole.

(4) Set the upper half of the center main housing

(29) on the crankshaft (33) and rotate it into place. Be

sure it is installed with the side marked f rent toward

the crankshaft gear. Set the two positioning dowels

(30) on the upper bearing mount. Install the center

main bearing cap (29) and torque the bolts (27) to 97-

102 ft-lbs.

(5) Place gasket (23) on each side of shim (24).

(6) Before installing bearing plate, tape keyway

and sharp edges on crankshaft to protect the oil seal