TM5-6115-585-34

NAVFAC P-8-262-12

TO-35C2-3-455-2

TM-05684C-34

Table 7-1. Button Code Letter and Size

Code

No.

Or

Letter

16

15

14

13

12

1

2

3

4

5

s

R

P

N

M

A

B

c

D

E

Part No.

147A186

147A187

147A188

147A189

147A190

147A147

147A148

147A149

147A150

147A151

Size

0.134

0.131

0.128

0.125

0.122

0.119

0.116

0.113

0.110

0.107

(b) Remove delivery valve cap nut and delivery

valve holder (figure 7-43). A 12 point socket or box

wrench must be used on delivery valve holder to keep

from damaging this part. Lift out delivery valve spring

only, and leave it out, replacing delivery valve holder,

and delivery valve cap nut and gasket.

(c) Turn blower wheel clockwise until Number

1 cylinder (closest to blower wheel) is on compression

stroke, which follows closing of intake valve.

(d) Set throttle lever on injection pump to wide

open or up position (compress stop solenoid plunger

spring or remove stop solenoid assembly). Connect

Number 1 cylinder fuel line to Number 1 pump outlet

so that fuel line projects from the engine, hanging

down. Position receptacle for fuel under the line. Con-

nect lines from fuel supply to transfer pumps, trans -

fer pumps to filter, and filter to injection pump,

operate fuel transfer pumps to obtain fuel pressure

at injection pump. This can be done on the unit by

turning master switch to PRIME & RUN, or just by

applying 24 volts dc across the transfer pump. Ro-

tate blower wheel about one inch counterclockwise so

that P.C. mark is below timing pointer hole.

(e) Rotate blower wheel clockwise until fuel

flows from Number 1 cylinder fuel line. Continue

rotating slowly clockwise until fuel stops flowing. The

point at which fuel stops flowing from Number 1 cyl-

inder fuel delivery line is the injection pump port

closing point. Stop rotation of engine at exactly the

port closing point (l-2 drops in 5-10 seconds).

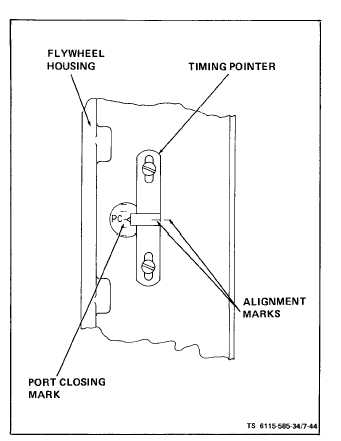

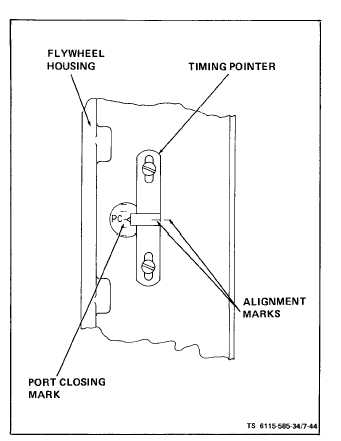

(f) Check timing pointer in the timing port on

the side of the generator adapter (figure 7-44). If

7-40

Figure 7-44. Timing Port and Port Closing Mark

timing pointer coincides with the P.C. mark stamped

on flywheel, the injection pump button thickness is

correct. If the P.C. mark on flywheel is below the

pointer, injection pump is closing early, and will re-

quire a thinner button. If the P.C. mark on flywheel

is above the pointer, injection pump is closing late

and will require a thicker button. Each mark on fly-

wheel indicates a difference of 0.006 inch button

thickness or 2 steps in button code number. (Example:

The P.C. mark on flywheel is above pointer. The

pointer indicates 1-1/ 2 marks difference. A button

0.009 inch thicker or 3 steps difference in button

number code is indicated. Since a Number 12 or M

button is installed, a letter R button is needed. )

(g) Remove injection pump and insert proper

timing button, taking the same precautions not to lift

the assembly containing face gear, when removing

timing button.

(h) Repeat injection pump installation.

(i) Check injection port closing point by re-

peating steps three through six. The timing pointer

should indicate the P.C. mark on flywheel. In no case

should pointer be more than 1/2 mark away from the

P.C. mark.

(j) Install delivery valve components. Be sure

ll parts are clean, and assembled carefully and