sharp tools, emery paper, grinding powder, or abra-

sives of any kind. If necessary, clean outer surfaces

of nozzle body (9) with a brass brush but, do not at-

tempt to scrape carbon from nozzle surfaces, because

severe damage to spray hole can result. Use a soft,

oil soaked cloth to clean nozzle valve. Clean interior

of nozzle cap nut.

f. Inspect. Inspect tappet surfaces of injector body

for nicks or roughening. If damaged, replace injector

body.

TM5-6115-585-34

NAVFAC P-8-623-34

TO-35C2-3-455-2

TM-05684C/05685B-34

h. Assemble.

(1) Rinse valve (7, figure 7-46) and nozzle (9)

thoroughly in clean fuel oil before assembly. Valve

must be free in the nozzle. Lift valve (7) about one-

third out of nozzle and release; valve should slide

back to seat without aid when assembly is held at 45

degree angle. If necessary, work valve into nozzle

body. Using dry compressed air, blow out fuel inlet

(14).

g. Repair. If cleaning will not eliminate a nozzle

(2) Remove all pressure on nozzle spring by

defect, replace nozzle.

loosening adjusting screw (3).

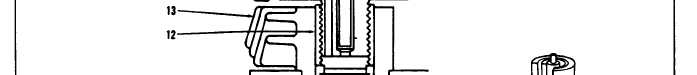

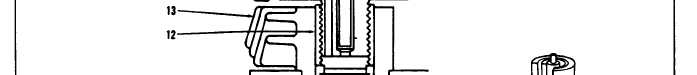

1. Pipe plug

7. Valve

12. Nozzle cap nut

2. Cover

8. Valve seat

13. Adapter

3. Pressure adjusting screw

9. Nozzle assembly

14. Fuel inlet

4. Gasket

10. Nozzle gasket

15. Injector body

5. Pressure adjusting spring

11. Cylinder head

16. Gasket

6. Spindle assembly

17. Heat shield

TS 6115-585-34/7-46

Figure 7-46. Fuel Injector

7-43