TM 5-6115-584-12

NAVFAC P-8-622-12

TO-35C2-3-456-1

TM-05682C-12

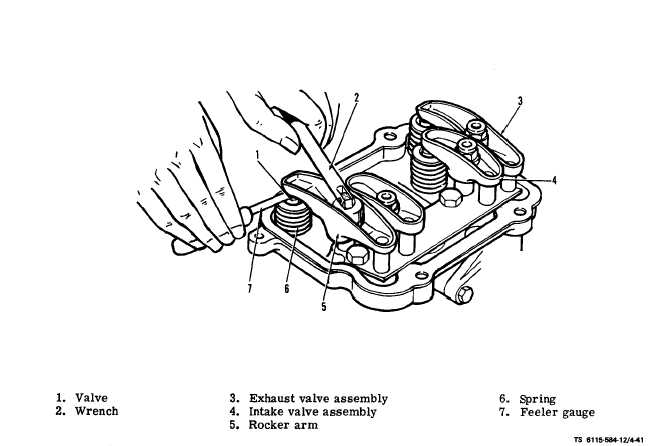

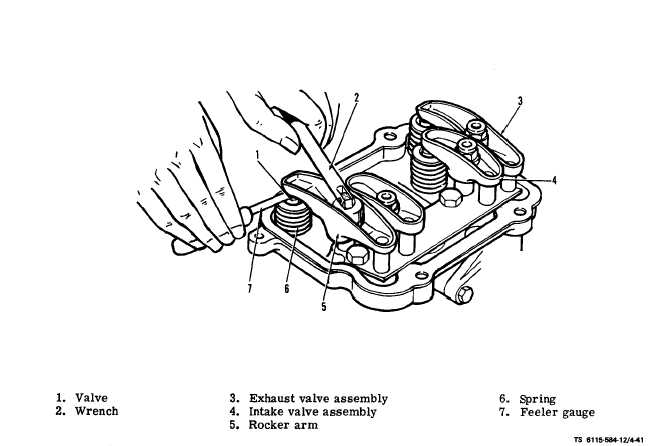

Figure 4-41. Checking and Adjusting Rocker Arm to Valve Clearance

Always check and adjust the valve tappet clearance

head. Correct valve clearance is 0.010 for intake

when the engine is at an ambient of approximately

70°F (18°C). Remove rocker cover and proceed as

follows :

Turn blower wheel clockwise only.

(1) Using 5/8" socket wrench and extension, turn

the blower wheel clockwise until No. 1 cylinder is on

its compression stroke, which follows the closing of

its intake valve. See figure 4-41 for identification of

intake valve assembly.

(2) Continue clockwise rotation until the letter

“A” appears in the timing port on the side of the

generator adapter. This puts No. 1 cylinder in the

power stroke with both valves closed.

(3) By using a feeler gauge, check the clearance

between the rocker arm and the valve stem cap. See

figure 4-41. Increase or reduce the clearance until

the proper gap is established, adjusting with the lock-

nut which secures the rocker arm to the cylinder

4-52

valve, 0.007 for exhaust valve.

(4) To adjust the valve clearance for No. 2 cyl-

inder, turn the blower wheel clockwise 180° until the

letter “B“ appears in the timing port and adjust valves

as given in step 3.

(5) Install rocker cover and tighten screws 7 to

8 ft-lb.

4-47. INJECTOR NOZZLE ASSEMBLY AND FUEL

LINES.

a. Inspect.

(1) Injector Nozzle Assembly (see figure 4-42).

Inspect for leaking fuel. Inspect fuel fittings for tight-

ness.

(2) Fuel Lines. Inspect fuel lines for leaks and

damage to fittings.

4-48. GLOW PLUG ASSEMBLIES.

a. Inspect (see figure 4-42). Inspect glow plugs for

physical damage. Check that electrical lead to glow