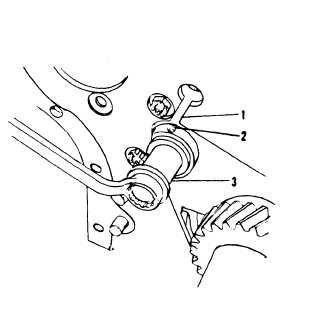

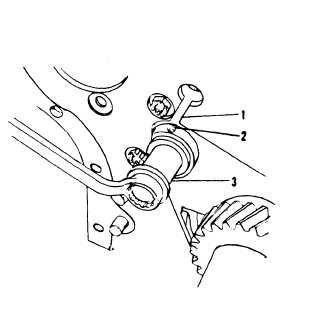

1. Slot

2. Oil hole

3. Idler gear shaft

ME 6115-545-34/14-35

Figure 14-35. Idler Gear Shaft Installation

(3) If idler gear shaft is scored or worn it

must be replaced The specified outer diameter on

both ends of the idler gear shaft is 0.999”-1.000”.

Install a 9/16 -18 adapter in the end of the idler

gear shaft. Install the end of the slide hammer into

the adapter and remove the idler gear shaft from the

cylinder block.

d. Camshaft Gear Removal. Refer to para-

graph 14-77 for removaI procedures.

e.

Crankshaft Gear Removal. Use bar type

puller and remove crankshaft gear.

f .

Hydraulic Gear Removal. (Class 1 sets

only (para 14-14)

14-73. Timing Gears and Housing Cleaning and In-

spection.

Clean cover and gears using cleaning sol-

vent, Federal Specification P- D-680.

b. Clean all gasket material from timing gear

cover using care to prevent scoring or gouging of

surface.

c. Inspect front support plate for damage and

wear.

d. Inspect idler gear shaft for scoring or

wear The center diameter on both ends must be

0.999 to 1,000 inch.

e.

Inspect all gears for excessive wear and

chipped or broken gear teeth

14-74. Timing Gears and Housing Repair.

a.

Repair is limited to replacement of

housing, front support

worn or damaged.

b. Replace idler

excessively worn beyond

to step d. above.

14-75. Installation.

plate, or gears if badly

gear shaft if scored or ex-

the allowable limits. Refer

a.

Crankshaft Gear Installation

—

(1) Install woodruff key in crankshaft.

(2) Heat gear in oil to a temperature of

approximately 300° F.

(3)

a mixture of

(4)

Coat crankshaft at gear location with

white lead and oil.

Drive or press gear onto crankshaft.

CAUTION

Use asbestos gloves when handling

the heated gear.

(5) When crankshaft is installed in engine

make certain that timing mark a crankshaft gear

is aligned with timing mark, on camshaft gear when

crankshaft gear is installed.

b. Camshaft Gear Installation. See figure

14-35 and proceed as follows:

(1) Insert idler gear shaft into cylinder.

Block bore so that oil hole on top of shaft aligns

with slot in front plate.

gear

until

(2) Insert washer and capscrew into idler

shaft (see fig. 14-34) and tighten capscrew

shaft bottoms in cylinder block

NOTE

The bore size of the roller bearing

is 1.000-1.008 inches and the

outer diameter of the outer race of

the bearing is 1.980-1.981 inches.

The bore size of the idler gear is

1.9785-1.9795 inches and the bore

size of the groove in the idler gear

for the spacer is 2.068-2.078

inches. If the bearing assembly is

worn, drive the outer races out with

a punch and press in the new races

until they contact the newly installed

spacer.

14-74