Section X. WATER PUMP AND FAN

14-56. General.

a. The water pump is a centrifugal type pump that

circulates coolant through the engine and radiator.

The pump is mounted on the front of the cylinder

block and is belt driven from the crankshaft pulley.

Coolant is drawn through the inlet opening by the

pump impeller and forced through the outlet in the

backside of the volute and into the cylinder block, and

the lube oil cooler.

b. The water pump shaft and bearing assembly

does not require lubrication because the bearing is of

the sealed-for-life type. A water slinger on the

pulley end of the shaft slings any coolant which might

seep past the seal assembly out the cored opening in

the pump body, thus preventing coolant from coming

in contact with the shaft bearing. The shaft and

bearing assembly is secured in the pump body by a

press fit and a retaining snap ring. The seal be-

tween the impeller and pump body is of the packless

type. The seal assembly is spring loaded and is

pressed into the pump body forming a leakproof seal

at this point,

c. The fan is located behind the radiator on the

front of the engine.

The fan is belt driven from the

engine and draws cooling air through the louvered

panel at the rear of the unit and exhausts it through

the radiator core, shutter and grille.

14-57. Removal and Disassembly.

a. Water Pump Removal.

Refer to Operator and Organizational Maintenance

Manual.

b. Fan Removal.

Refer to Operator and Organizational Maintenance

Manual.

c. Water Pump Disassembly.

(1) Place water pump in a press and remove

pulley hub.

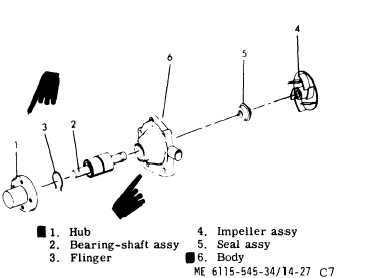

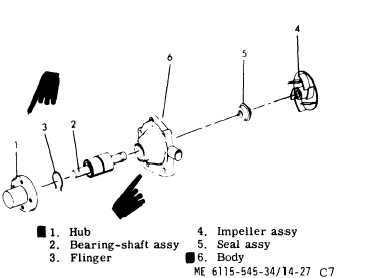

(2) See figure 14-27 and disassemble water

pump as illustrated.

(3) Place water pump assembly in position on

a press, impeller end up. Make certain the pump

rests on back of pump body and not on the water inlet

or drain hole.

Press end of shaft until shaft and

bearing assembly is out of the pump body. Remove

impeller from the pump body.

(4) Drive out seal assembly with a drift pin or

rod and a hammer. ,

14-58. Inspection and Repair.

a. Check condition Of pump shalt and bearing

assembly by rotating the bearing. If the bearing

Figure 14-27. Water Pump

is binding, running dry from lack of lubricant, or

feels rough, the shaft and bearing assembly must be

replaced. If the slinger is damaged, it must be

replaced.

CAUTION

Do not clean shaft and bearing assembly

in cleaning solvent because the lubricant

will be washed from the bearing.

b. Check condition of the ceramic seal insert

bonded to the pump impeller. If it is rough, cracked,

or chipped, replace the impeller.

c. Thoroughly clean pump body with cleaning

solvent, Federal Specification P-D-680.

d. Check condition of bearing bore in the body.

Replace pump body if cracks are evident.

e. Replace the water pump seal assembly.

14-59. Reassembly and Installation.

a. Pump Reassembly.

(1) Position pump body on press, impeller end

up. Position seal assembly in the pump body. Place

seal installer tool on the seal and press seal into

pump body, making certain the carbon sealing sur-

face is not damaged.

CAUTION

Face of seal assembly must be free of

oil, grease, and fingerprints before seal

assembly is installed.

(2) Position pump body on press, bearing bore

up. Start shaft and bearing assembly into bore,

slinger end of shaft down. Press shaft until bearing

seats on shoulder in the pump body. The slinger

must be 1-15/16 inches from the end of the shaft

Change 7 14-61