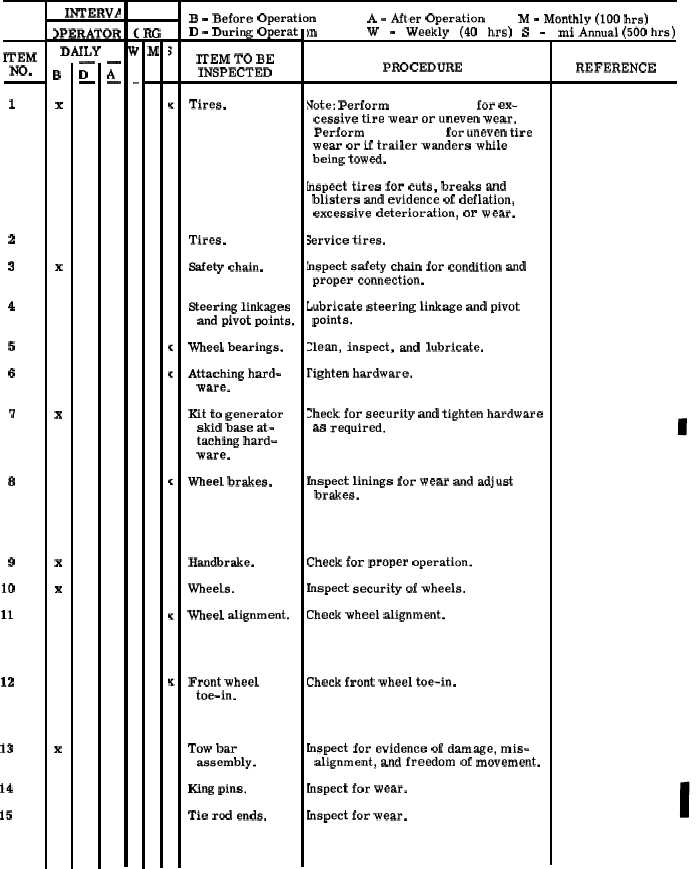

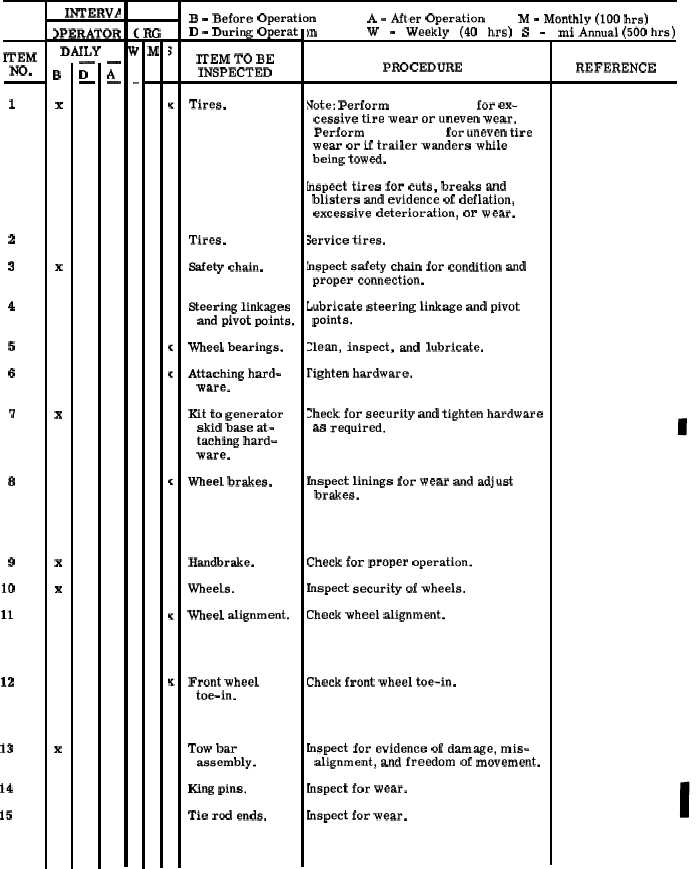

T a b l e

4 - 5 .

W h e e l

M o u n t i n g

K i t

P r e v e n t i v e

M a i n t e n a n c e

C h e c k s

a n d

S e r v i c e s

ITEM

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

INTERVA

)PERATOR

DAILY

B

x

x

x

x

x

x

—

D

—

—

A

—

B - Before Operation

A - After Operation

M - Monthly (100 hrs)

D - During Operat

ITEM TO BE

INSPECTED

Tires.

Tires.

Safety chain.

Steering linkages

and pivot points.

Wheel bearings.

Attaching hard-

ware.

Kit to generator

skid base at-

taching hard-

ware.

Wheel brakes.

Handbrake.

Wheels.

Wheel alignment.

Front wheel

toe-in.

Tow bar

assembly.

King pins.

Tie rod ends.

m

W

-

Weekly

(40

hrs)

S

-

PROCEDURE

Note: Perform I t e m N o . 1 0 for ex-

cessive tire wear or uneven wear.

Perform I t e m N o . 1 1 for uneven tire

wear or if trailer wanders while

being towed.

hspect tires for cuts, breaks and

blisters and evidence of deflation,

excessive deterioration, or wear.

Service tires.

hspect safety chain for condition and

proper connection.

Lubricate steering linkage and pivot

points.

:lean, inspect, and lubricate.

I’ighten hardware.

Zheck for security and tighten hardware

as required.

fnspect linings for wear and adjust

brakes.

Check for proper operation.

Inspect security of wheels.

Check wheel alignment.

Check front wheel toe-in.

inspect for evidence of damage, mis-

alignment, and freedom of movement.

tnspect for wear.

Lnspect for wear.

mi Annual (5OO hrs)

REFERENCE

( p a r a 4 - 3 3 )

( p a r a 4 - 3 3 )

( p a r a 2 - 2 6 )

( p a r a 3 - 3 a n d 3 - 4 )

( p a r a 4 - 3 4 )

( p a r a

4 - 4 2 )

( p a r a 4 - 3 5 )

( p a r a 2 - 2 6 )

( p a r a

4 - 3 3 )

( p a r a 4 - 3 6 )

( p a r a 4 - 3 7 )

( p a r a

2 - 2 6 )

( f i g . 4 - 1 2 )

( f i g . 4 - 1 2 )

C h a n g e 1

4 - 2 3