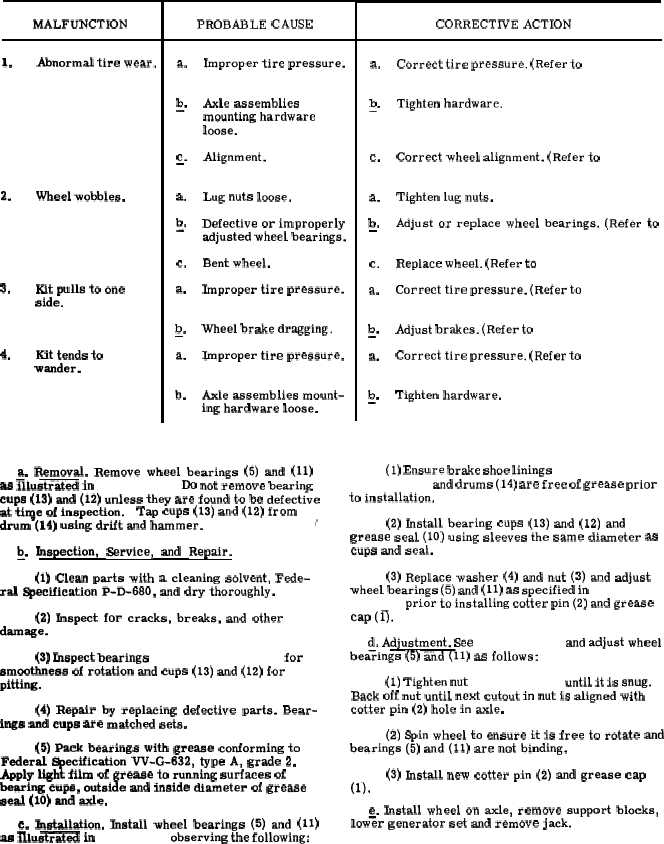

T a b l e

4 - 6 .

W h e e l

M o u n t i n g

K i t

T r o u b l e s h o o t i n g

MALFUNCTION

1.

2.

3.

4.

Abnormal tire wear.

Wheel wobbles.

Kit pulls to one

side.

Kit tends to

wander.

PROBABLE CAUSE

a.

b

—“

c.

—

a.

b

-“

c.

a.

b

—“

a.

b.

Improper tire pressure.

Axle assemblies

mounting hardware

loose,

Alignment.

Lug nuts loose.

Defective or improperly

adjusted wheel bearings.

Bent wheel.

Improper tire pressure.

Wheel brake dragging.

Improper tire pressure.

Axle assemblies mount-

ing hardware loose.

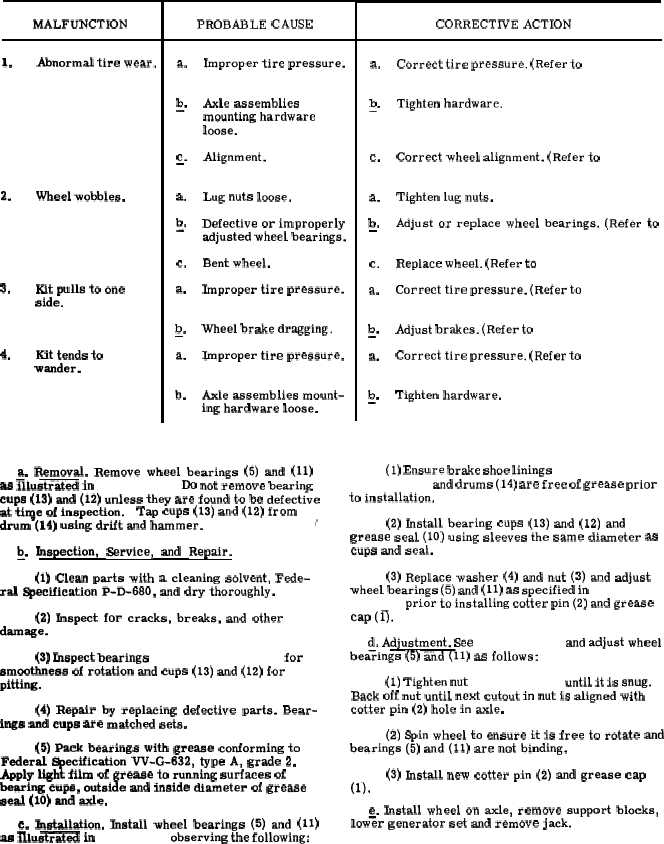

a. Removal. Remove wheel bearings (5) and (11)

as illustrated in f i g u r e 4 - 1 2 . Do not remove bearing

cups (13) and (12) unless they are found to be defective

at ti~e of inspection.

Tap cups (13) and (12) from

drum (14) using drift and hammer.

/

~.

Inspection,

Service,

and

Repair.

(1) Clean parts with a cleaning solvent, Fede-

ral Specification P-D-680, and dry thoroughly.

(2) Inspect for cracks, breaks, and other

damage.

(3) Inspect bearings ( 5 a n d 1 1 , f i g . 4 - 1 2 ) for

smoothness of rotation and cups (13) and (12) for

pitting.

(4) Repair by replacing defective parts. Bear-

ings and cups are matched sets.

(5) Pack bearings with grease conforming to

Federal ~ecification W-G-632, type A, grade 2.

Apply light film of grease to running surfaces of

bearing cups, outside and inside diameter of grease

seal (10) and axle.

c. Installation. Jnstall wheel bearings (5) and (11)

as Illustrated

in f i g u r e 4 - 1 2 observing the following:

CORRECTIVE ACTION

a.

Correct tire pressure. (Refer to

p a r a g r a p h

4 - 3 3 . )

b

Tighten hardware.

—.

c.

a.

b

—.

c.

a.

b

—.

a.

b

—.

Correct wheel alignment. (Refer to

p a r a -

g r a p h

4 - 3 6 . )

Tighten lug nuts.

Adjust or replace wheel bearings. (Refer to

p a r a g r a p h

4 - 3 4 . )

Replace wheel. (Refer to p a r a g r a p h 4 - 3 3 . )

Correct tire pressure. (Refer to

p a r a g r a p h

4 - 3 3 . )

Adjust brakes. (Refer to p a r a g r a p h 4 - 3 5 . )

Correct tire pressure. (Refer to

p a r a g r a p h

4 - 3 3 . )

Tighten hardware.

(1) Ensure brake shoe linings ( 1 7 a n d 1 8 ,

f i g u r e

4 - 1 2 ) and drums (14) are free of grease prior

to installation.

(2) Install bearing cups (13) and (12) and

grease seal (10) using sleeves the same diameter as

cups and seal.

(3) Replace washer (4) and nut (3) and adjust

wheel bearings (5) and (11) as specified in

p a r a g r a p h

4 - 3 4

d . prior to installing cotter pin (2) and grease

cap (0.

d. Adjustment. See

f i g u r e

4 - 1 2 and adjust wheel

bea;ings (5) and (!11) as follows:

(1) Tighten nut ( 3 , f i g . 4 - 1 2 ) until it is snug.

Back off nut until next cutout in nut is aligned with

cotter pin (2) hole in axle.

(2) Spin wheel to ensure it is free to rotate and

bearings (5) and (11) are not binding.

(3) Install new cotter pin (2) and grease cap

(l).

e. Install wheel on axle, remove support blocks,

low% generator set and remove jack.

4 - 2 5