f i g .

4 - 7 ) for loose connection, frayed wires, cor-

rosion, and loose mounting.

~.

Testing.

(1) Remove thermostat switch ( 9 , f i g . 4 - 7 ) and

plug heat exchanger opening.

(2) Fill a container with clean water and place

thermometer in water. tWspend temperature sens-

ing end of switch in water.

(3) Heat water and check switch for continuity.

Observe water temperature. Switch continuity

should be indicated between terminals up to 150°

+5°F and open thereafter.

(4) Permit water to cool and observe that con-

tinuity is again indicated at 130° +50F.

(5) If switch fails to meet above tests, it should

be replaced.

i l l u s t r a t e d ( 9 , f i g . 4 - 7 ) .

c

. R

e p l a c e m e n t . Replace thermostat switch as

4 - 2 4 .

H e a t i n g

E l e m e n t s

I n s p e c t i o n ,

T e s t i n g

a n d

R e p l a c e m e n t .

See f i g u r e 4 - 7 and proceed as follows:

&

Inspec tion.

(1) Check that heating elements ( 6 , f i g . 4 - 7 )

are screwed securely into both ends of electric win-

terisation pipe (10).

(2) Check that electrical connections to both

heater elements are secure and protective sleeving

is installed.

b.

Testing. To test heating element, proceed

as ~ollows:

(1) Remove electrical lead from one terminal

of heating element ( 6 , f i g . 4 - 7 ) .

(2) Use a multimeter and check resistance

between heating element case and terminal. Reading

should indicate an open circuit.

(3) Check resistance between heating element

terminals. Resistance should be between 27 and 33

ohms.

(4) If heater element resistance check does

not satisfy above requirements, heating element is

defective and must be replaced.

c . R e p l a c e m e n t . R e m o v e a n d r e p l a c e h e a t i n g

e l e m e n t s

( 6 )

a s

i l l u s t r a t e d

i n

f i g u r e

4 - 7 .

4 - 2 5 .

H o s e s

a n d

F i t t i n g s

I n s p e c t i o n ,

R e p a i r

a n d

R e p l a c e m e n t .

See f i g u r e 4 - 7 and proceed as follows:

a.

Inspection.

(1) Check all hoses for cracks and coolant

leaks.

(2) Check hoses and pipe fittings for

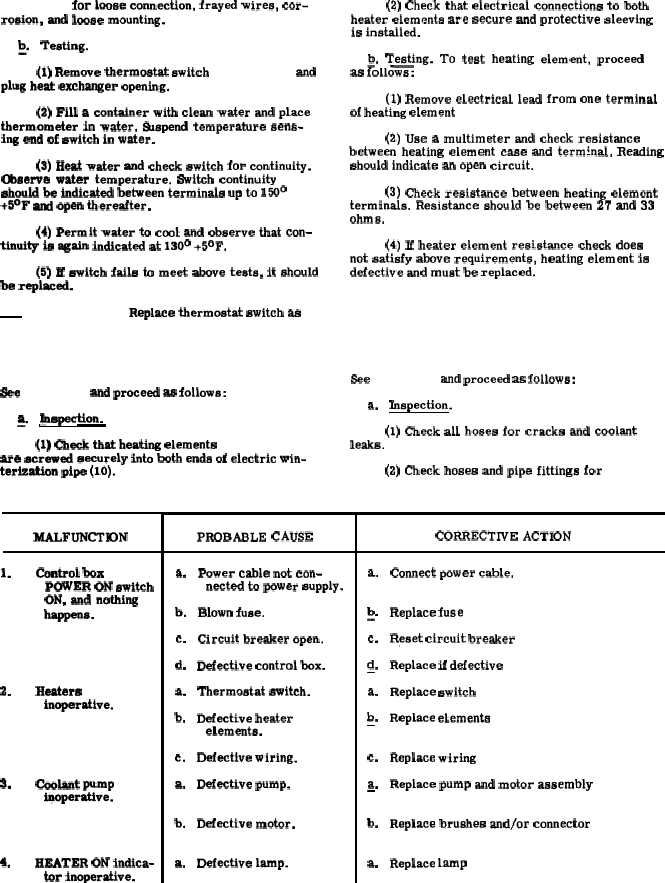

MALFUNCTK)N

1.

2.

3.

4.

control box

POWER ON switch

ON, and nothing

-s.

Heaters

inoperative.

coolant pump

iqoperattve.

HEATER ON indica-

tor inoperative.

T a b l e

4 - 4 .

E l e c t r i c

W i n t e r i z a t i o n

K i t

T r o u b l e s h o o t i n g

PROBABLE CAUSE

a.

b.

c.

d.

a.

b.

c.

a.

b.

a.

Power cable not con-

nected to power supply.

Blown fuse.

Circuit breaker open.

Defective control box.

Thermostat switch.

Defective heater

elements.

Defective wiring.

Defective pump.

Defective motor.

Defective lamp.

CORRECTIVE ACTION

a.

b

-“

c.

d

—“

a.

b

—’

c.

a.

—

b.

a.

Connect power cable.

Replace fuse ( p a r a 4 - 2 8 ) .

Reset circuit breaker ( p a r a 4 - 2 7 ) .

Replace if defective ( p a r a 4 - 2 7 ) .

Replace switch ( p a r a 4 - 2 3 ) .

Replace elements ( p a r a 4 - 2 4 ) .

Replace wiring ( p a r a 4 - 2 6 ) .

Replace pump and motor assembly

( p a r a

4 - 2 2 ) .

Replace brushes and/or connector

( p a r a

4 - 2 2 ) .

Replace lamp ( p a r a 4 - 2 8 ) .

4 - 1 9