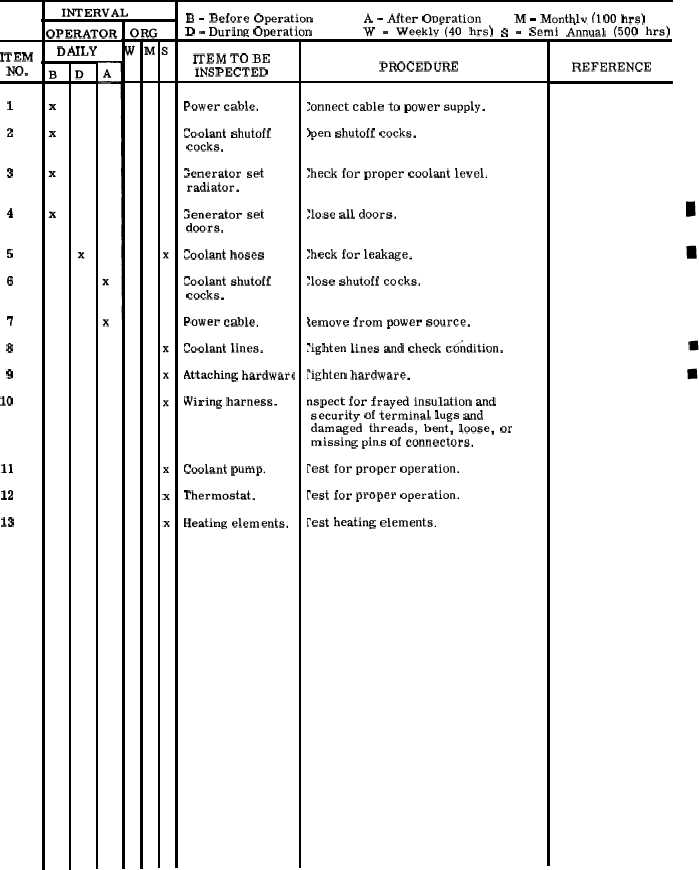

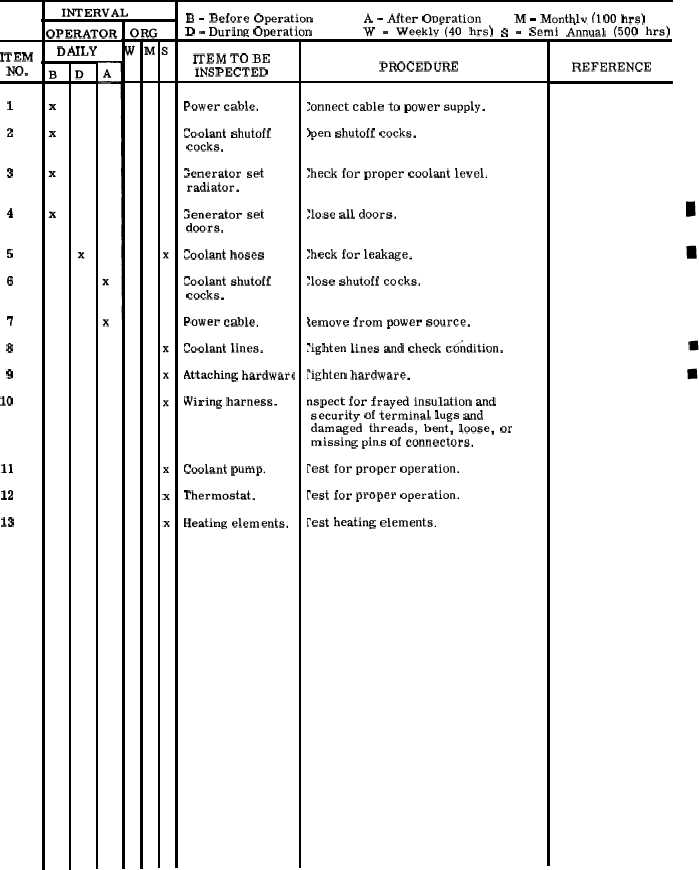

Table 4-3. Electric Winterization Kit Preventive Maintenance Checks and Services

ITEM

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

DAILY

B - Before Operation

A - After Operation

M - Monthly (100 hrs)

D - During Operation

W - Weekly-(40 hrs) S - Semi A-nnual (500 hrs)

l’TEM TO BE

INSPECTED

Power cable.

Coolant shutoff

cocks.

;enerator set

radiator.

Senerator set

doors.

Coolant hoses

Coolant shutoff

cocks.

Power cable.

Coolant lines.

Attaching hardwart

Wiring harness.

Coolant pump.

Thermostat.

Heating elements.

PROCEDURE

:onnect cable to power supply.

)pen shutoff cocks.

:heck for proper coolant level.

;lose all doors.

;heck for leakage.

;lose shutoff cocks.

temove from power source.

?ighten lines and check ~ndition.

~ighten hardware.

nspect for frayed insulation and

security of terminal lugs and

damaged threads, bent, loose, or

missing pins of connectors.

rest for proper operation.

rest for proper operation.

pest heating elements.

REFERENCE

(para 2-25 and 4-18)

(para 2-25)

(para 3-41)

( f i g . 1 - 1 a n d 1 - 2 )

(para 4-22)

(para 2-25)

(para 2-25 and 4-19)

(para 4-22)

(para 4-22)

(para 4-26)

(para 4-22)

(para 4-23)

(para 4-24)

Change 1

4-17