TM 5-6115-465-34

TO 35C2-3-446-2

NAVFAC P-8-625-34

TM06858B/06859D-34

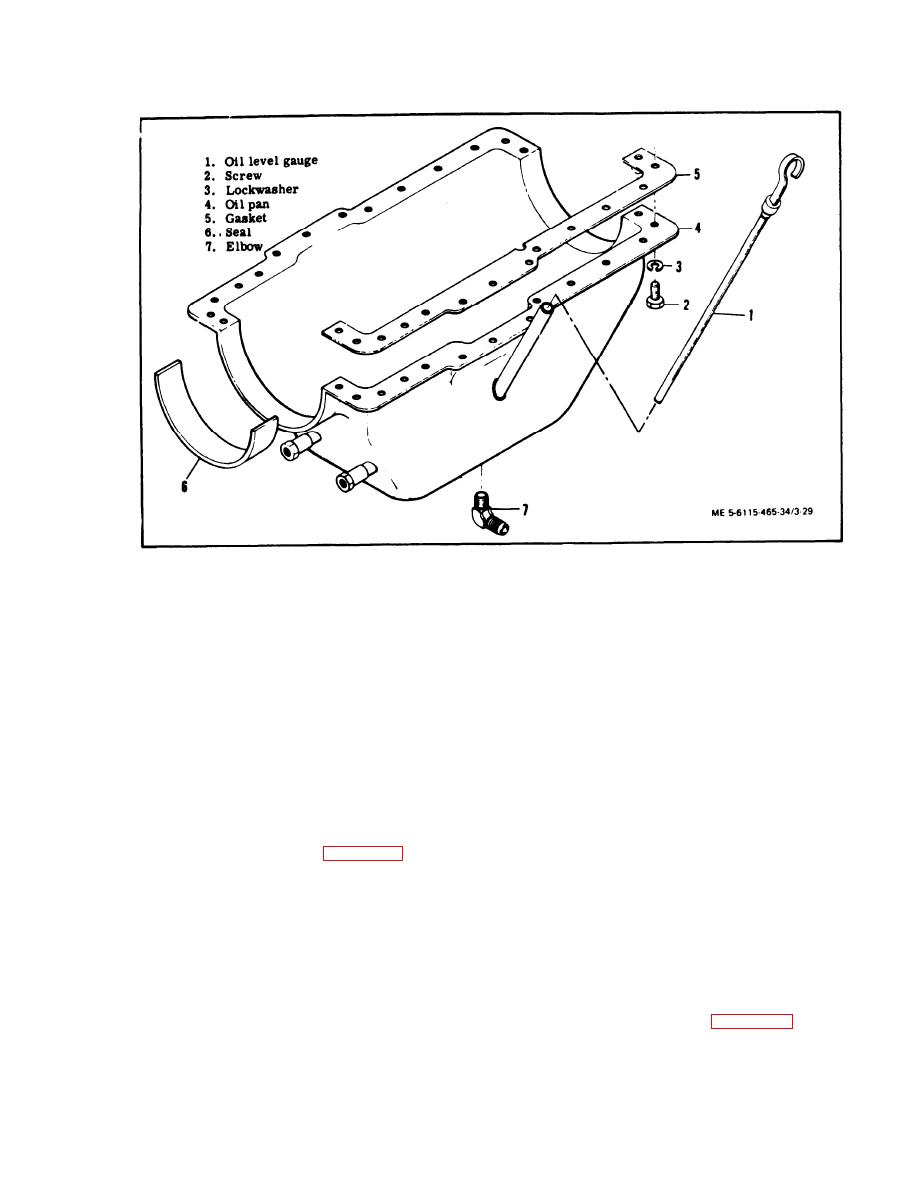

Oil Pan Assembly

Figure 3-29.

(6) Inspect gears (18 and 19) for chipped or

(4) Using a suitable puller, remove gear (12).

broken teeth, excessive wear or other damage.

(5) Remove screws (13 and 15) and lockwashers

(7) Inspect shafts (20 and 21) for cracks,

(14 and 16) to remove cover plate (17).

scores and deep wear patterns. Check that shaft (20)

rotates freely in pump body. Check that gear (18)

(6) Remove driven gear (18).

rotates freely on shaft (21).

(7) Withdraw drive gear (19) and drive shaft

(8) Inspect pump body (22) for cracks, breaks,

(20) as a unit. Press gear from shaft.

and other damage. Check gear bores for rub marks

from contact with pumping gears.

(8) Press shaft (21) from pump body (22).

(9) Check all threads for crossing, stripping

c. Cleaning, Inspection, and Repair.

or peening.

(1) Clean all parts in dry cleaning solvent

(10) Inspect screen (3) for rips, tears, breaks

(Federal Specification P-D-680) and dry thoroughly.

and clogging.

(2) Inspect spring (9, figure 3-30) for cracks,

(11) Repair minor thread damage with a thread

breaks and distortion.

chaser.

(3) Inspect plunger (l0) and bore of valve

(12) Remove minor nicks and burrs with crocus

body (n) for scores, scratches, and deep wear

cloth and oil Clean the part in dry cleaning solvent

patterns. Check that plunger moves freely in valve

and dry thoroughly with filtered compressed air.

body.

(13) Replace any parts worn or damaged be-

(4) Check gear (12) for chipped or broken

yond repair.

teeth, excessive wear, or other damage.

d. Assembly.

(5) Inspect cover plate for cracks and warp-

(1) Press drive gear (19, figure 3-30) onto

age. Check inner face for deep wear marks or scores

shaft (20).

from contact with gears.

3-47