TM 5-6115-465-34

TO 35C2-3-446-2

NAVFAC P-8-625-34

TM 06858B/06859D-34

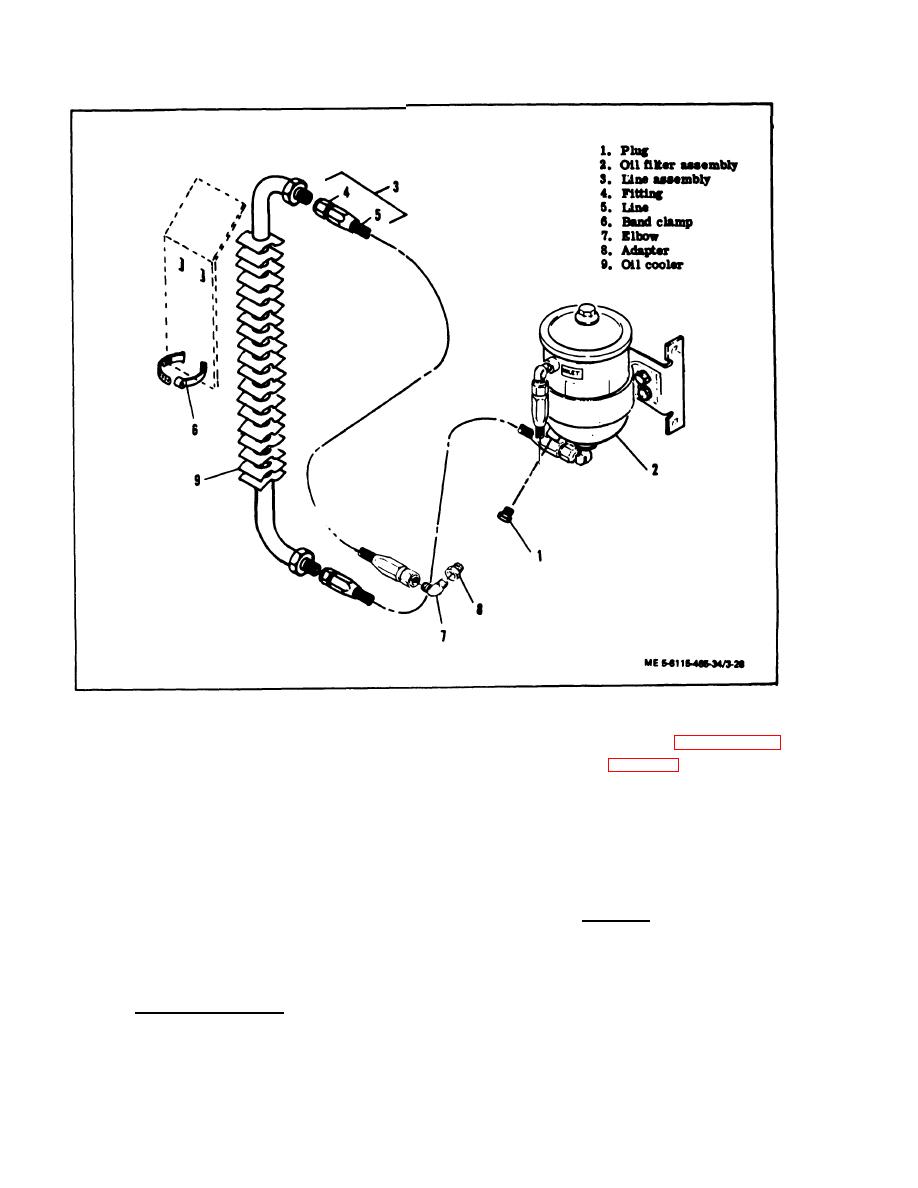

Oil Cooler Assembly Removal and Installation

Figure 3-28.

(1) Remove oil pan assembly (paragraph 3-36).

(3) Inspect and replace oil level gauge in ac-

cordance with instructions provided in the Operator

(2) Remove screws (1, figure 3-30)and lock-

and Organizational Maintenance Manual.

washers (2) to remove oil pump.

(4) Inspect oil pan for cracks, dents, broken

b. Disassembly.

welds and leaks.

(5) Check all threads for crossing, stripping

(1) Remove oil pickup screen (3).

and peening.

(2) Remove pressure relief valve (4), lock-

(6) Repair cracks and broken welds in oil pan

washers (55) and. seal (6). Discard seal.

by welding.

(7) Repeat minor thread damage with a thread

CAUTION

chaser.

(8) Replace any parts damaged beyond repair.

Spring is under tension. Use care when

c. Installation. Using new gaskets and seals,

removing roll pin.

install oil pan assembly in reverse order of removal

procedures.

3-37. OIL PUMP ASSEMBLY.

(3) Remove roll pin (7) and withdraw retainer

(8), spring (9) and plug (10) from valve body (11).

a. Removal.

3-46