P-8-627-34 T O 35C2-3-442-2

T M 5-6115-457-34

TM-07464A-35

WARNING

Welding operations produce heat,

highly toxic fumes, injurious

radiation, metal slag and air-

b o r n e particles. Welding gog-

gles, with proper tinted lenses,

apron or jacket and welder's

boots are required.

b . Weld cracks.

c. Remove damaged paint with a

s u i t a b l e scraper. Blend in edges, prime,

and paint damaged areas.

9-15.

REASSEMBLY.

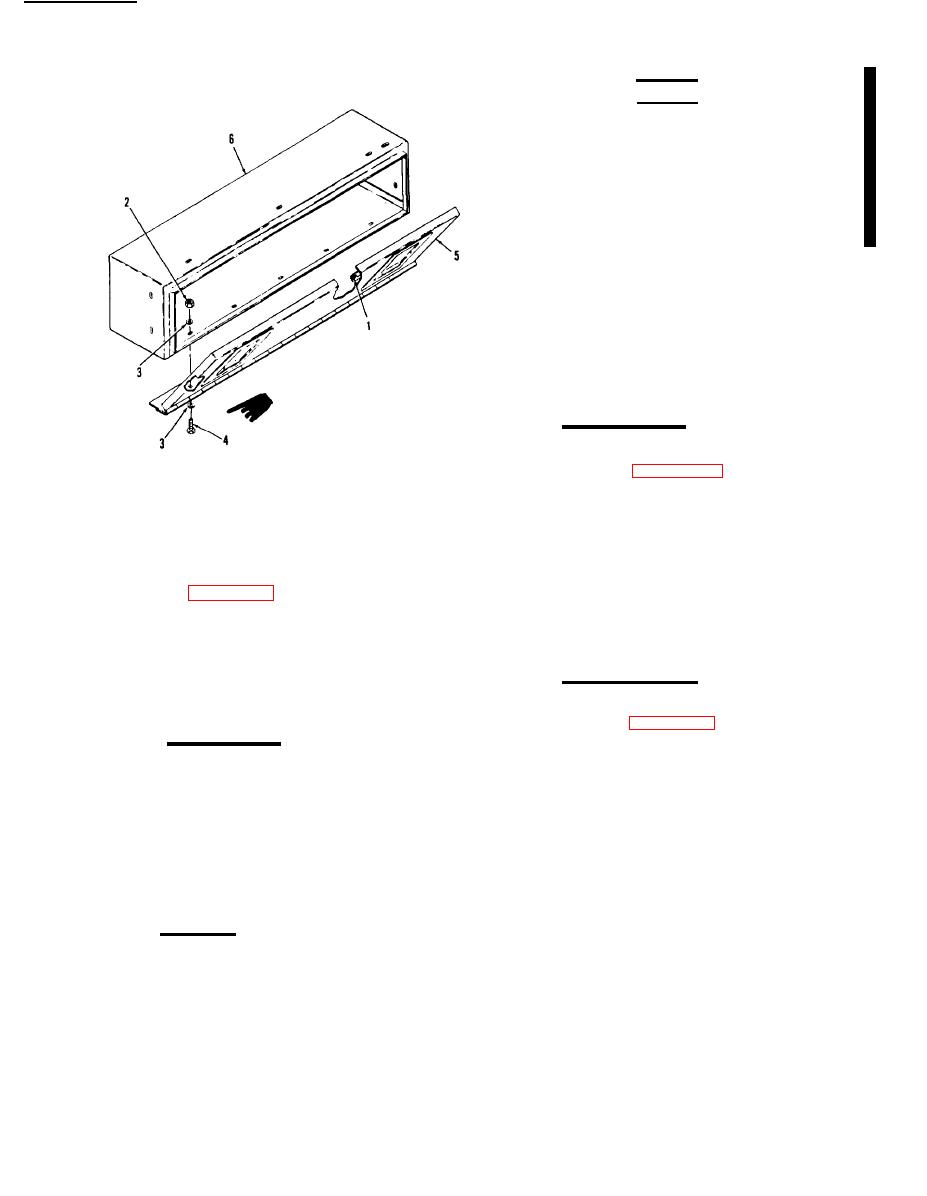

Refer to figure 9-2 and reassemble

the stowage tool box in the reverse order of

t h e numbers assigned. Pay particular

Figure 9-2. Stowage tool box,

attention to the following:

exploded view

a. Align cover (5) so that seal (1) makes

Legend to figure 9-2:

full contact on stowage box (6) prior to

tightening nuts (2).

4 . Screw (5)

1. Seal

2. Nut (5)

5. Cover

INSTALLATION.

9-16.

6 . Stowage box

3 . Washer (10)

Refer to figure 9-1 and install

INSPECTION.

9-13.

stowage-tool box assembly in base assem-

bly. Pay particular attention to the

a. Inspect sheet metal parts for cracks,

following:

dents, distortion, and worn hinges.

a. Install stowage tool box and secure

b . Inspect seal for cuts, cracks, and

with screws (16), nuts (17), and washers

(18), leaving nuts finger tight.

Inspect paint for damage.

c.

b. Align stowage tool box cover so that

9-14.

REPAIR.

it is flush with base assembly and tighten

nuts.

a. Straighten dented and distorted parts

using suitable tools.

Change 8

9-5