TM 5-6115-400-35

properly torqued. Never file or shim

(11) Install flywheel and flywheel housing.

a bearing cap to make the bearing

e. Crankshaft Gear Removal and Installation.

shell fit; install new bearing shells if

(1) The crankshaft gear may be removed

fit

on

the

crankshaft

is

from the crankshaft with a gear puller.

unsatisfactory.

The gear may be removed either with the

(7) Check end play on the crankshaft using a

crankshaft installed in the engine or after

dial indicator. The specified end play is

the crankshaft has been removed.

.007 inch-.015 inch and must not exceed

(2) To install crankshaft gear on crankshaft,

.023 inch. The end play is controlled by

install woodruff key in crankshaft. Heat

thrust flanges at the center main bearing

gear in oil to a temperature of

approximately 300 . Coat crankshaft, at

F

specified range, replace thrust flanges.

gear location, with a mixture of white lead

Thrust flanges are available in standard

and oil; drive or press gear onto

thickness (.151 inch-.153 inch) and .005

crankshaft.

inch, .010 inch, and .015 inch oversize.

Caution.

(8) Install connecting rod bearing caps and

Use asbestos gloves when handling

shells and check side clearance between

the heated gear. If crankshaft is

connecting rods and crankshaft journals.

installed In engine, make certain that

(9) Install oil pan, pump, and associated

timing mark on crankshaft is alined

tubing.

with timing mark on camshaft gear

(10) Install the timing gear housing cover.

when crankshaft gear is installed.

See figure 85.

61. Cylinder Block

a. General.

(1) The cylinder block is a one-piece casting

made of alloy cast iron. The cylinder

block is cored to receive removable wet-

type cylinder sleeves.

The cylinder

sleeves are surrounded by water jackets

which extend the full length of the cylinder

walls. Oil passages direct the oil from the

main oil gallery to the camshaft and main

bearings and through the rifle-drilled

connecting rods to the piston pins. A

horizontal oil passage through the center

of the cylinder block extends from the

main oil gallery to a vertical passage (on

the left side of the block) leading to a

small cavity from where two openings

extend to the rocker arm assemblies.

(2) The cylinder block, when ordered for

service, is furnished with camshaft

bearings, main bearing caps and

capscrews; the necessary plugs and

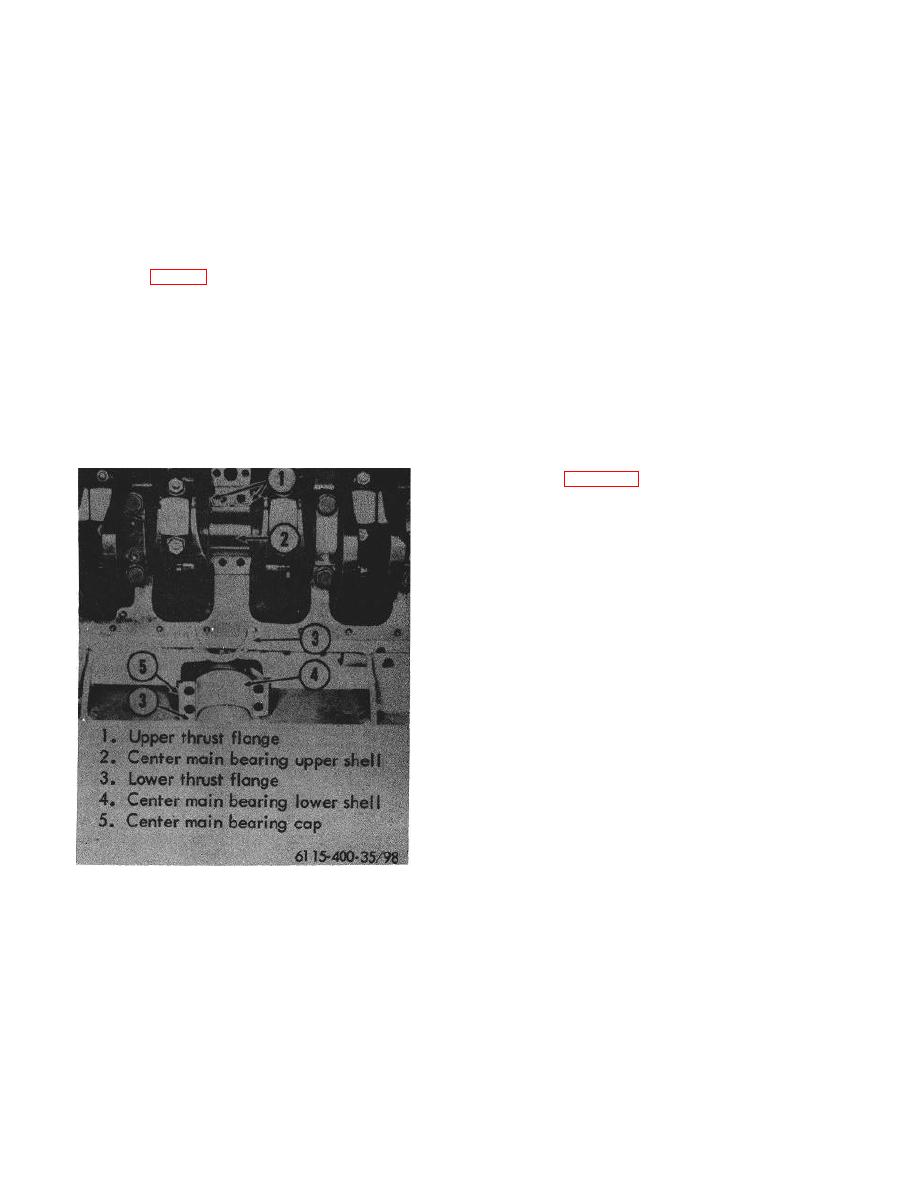

Figure 98. Center main bearing cap details.

various small parts.

135