TM 5-6115-400-35

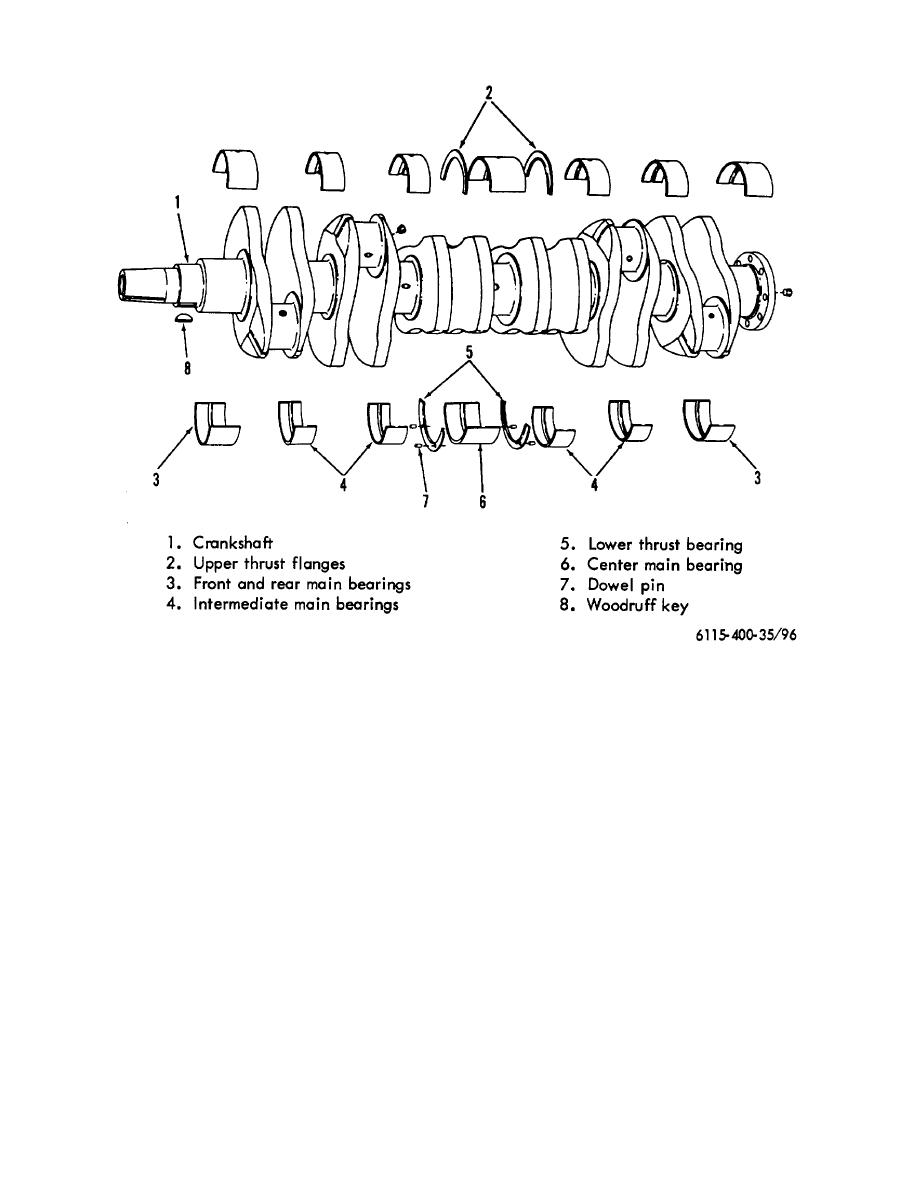

Figure 96. Crankshaft and main bearings.

area around plugs to prevent them from

If crankshaft is ground, the diameter of

loosening.

main bearing journals should be reduced

in steps of .010 inch, .020 inch, .030 inch,

d. Crankshaft Installation.

or .040 inch below 3.995 inches-3.996

(1) Install the upper halves of main bearing

inches to fit the undersize main bearing

shells in position in bearing seats of the

shells. If out-of-round or taper of journals

cylinder block.

exceeds .002 inch, crankshaft must be

Caution.

reground to a standard undersize or

Make certain the backs of bearing

replaced.

shells are free from dirt and grit

(4) Remove the hex-socket pipe plugs from

particles.

crankshaft and blow out all oil passages in

(2) Lubricate all crankshaft main bearing

crankshaft with compressed air. Reinstall

journals and lower crankshaft into position

plugs, tighten them securely until they are

in the cylinder block with flywheel flange

1/16 inch below crankshaft surface. Peen

end of crankshaft toward the rear.

133