TM 5-6115-400-35

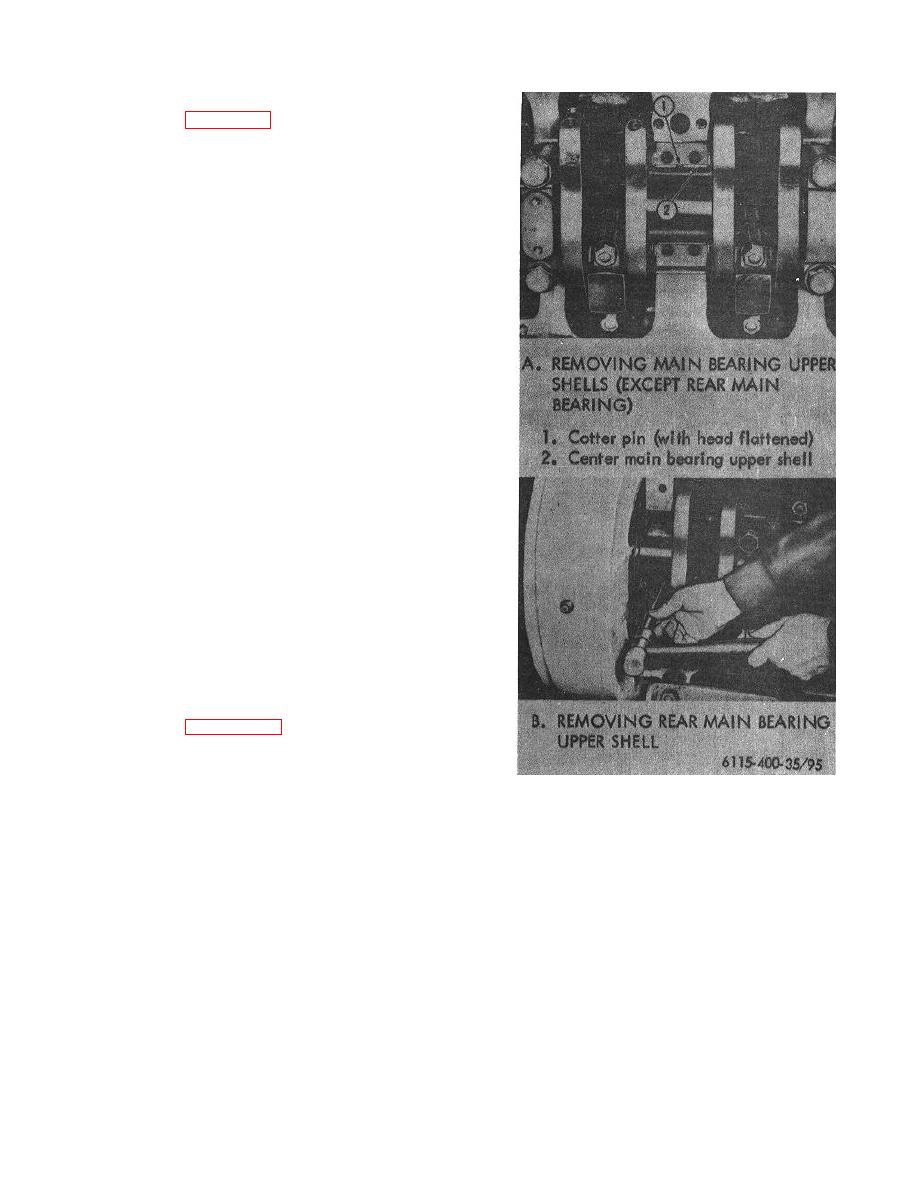

with a small curved rod as shown in

crankshaft.

(e) Inspect the crankshaft journals for

scoring, chipping, cracking, or signs

of overheating. If crankshaft has

been overheated (usually indicated

by discolored or blue bearing journal

surfaces) or is scored or excessively

worn, reconditioning or replacement

will be required.

Examine the

bearing journals for cracks if

overheating has occurred.

(f) Inspect each main bearing shell as

described in paragraph c above.

(2) Main bearing installation with engine

installed.

center main, as follows: Lubricate a

bearing shell with clean oil and roll it

around the crankshaft journal and

into position in the cylinder block.

Note.

The halves of the main bearing shells

are identical, therefore they may be

installed in either the upper or lower

positions.

(b) Install a bearing shell in position on

the dowel pin in the bearing cap.

Lubricate the bearing shell and

place the bearing cap in position on

the cylinder block. Install the cap

retaining capscrews and washers;

tighten the capscrews evenly to the

specified torque.

Refer to

Note.

The main bearing caps are numbered

1, 2, 3, etc.

indicating their

Figure 95. Removing main bearing upper shells.

respective positions.

flanges on the dowel pins in the

center main bearing cap, with the oil

(c) Lubricate and install the upper half

grooved side of flanges to the

of center main bearing shell. Install

outside of bearing cap. Lubricate

the upper halves of the thrust

and place bearing cap in position on

flanges (flanges without dowel pin

cylinder block with the number

holes) with oil grooved side of

facing the camshaft side. Install

flanges

toward

cheeks

of

cap retaining capscrews and

crankshaft. Install a bearing shell in

washers.

position on the dowel pin in the

center main bearing cap. Install the

lower halves of the thrust

131