TM 5-6115-400-35

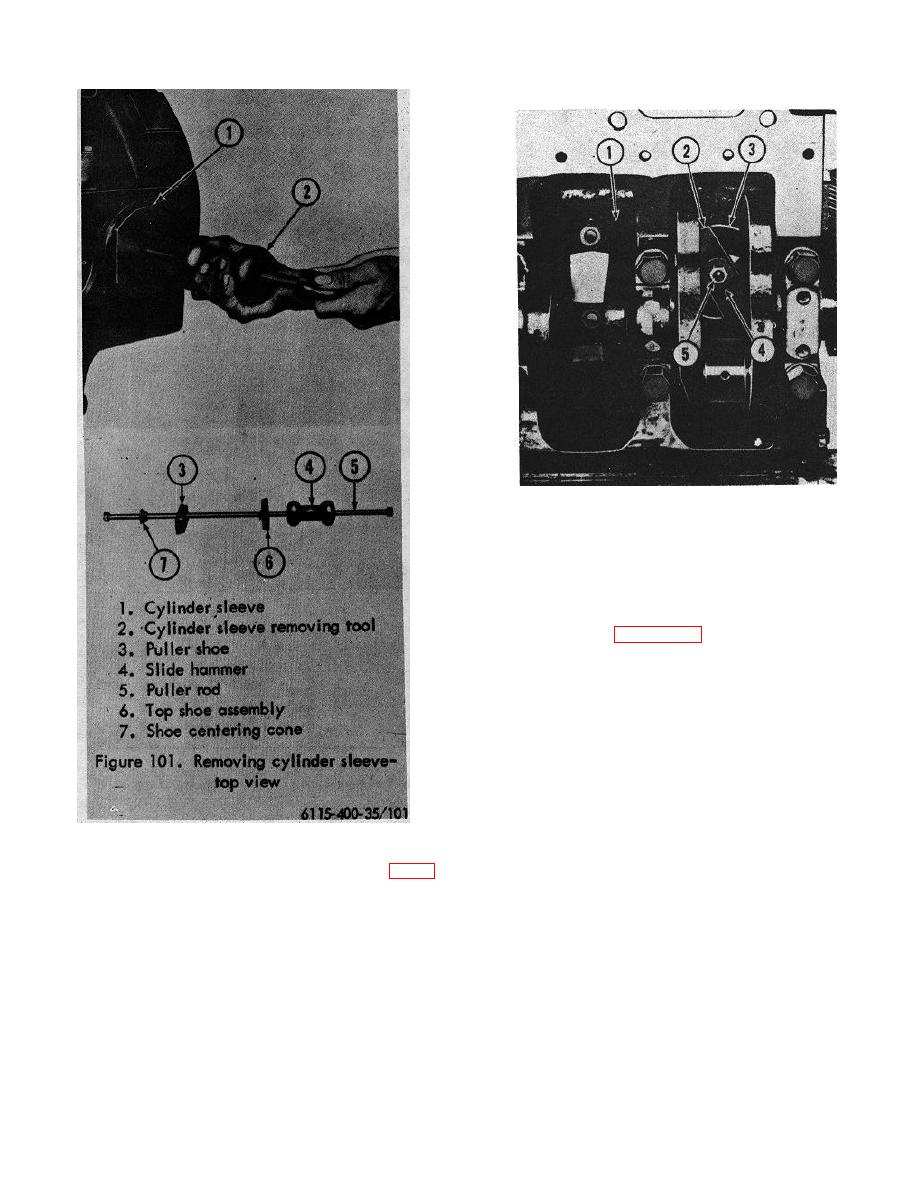

1.

Crankshaft

2.

Cylinder sleeve puller shoe

3.

Cylinder sleeve

4.

Shoe centering cone

5.

Puller rod

6115-400-35/102

Figure 108. Removing cylinder sleeve-bottom view.

(refer to following para d). The special sleeve tool,

shown in figure 103, is made from a new

cylinder sleeve. The sleeve is machined as

follows to assure proper relationship between

the lower surface of the sleeve flange and the

sleeve center line.

(a) Place the flange end of a new sleeve in

the chuck of a lathe.

(b) True the center line of the sleeve as

closely as possible to the lathe center by

using dial indicators at each end of the

sleeve.

Figure 101. Removing cylinder sleeve-top view.

the bottom of the counterbore as shown in figure

103. Total indicator reading should not exceed

.002 inch. If the total dial indicator reading

exceeds the specified limit, reworking the

counterbore is necessary

138