TM 5-6115-400-12

3-38. Fuel Lines

a. Refer to figure 3-31 for removal of fuel supply lines.

b. Refer to figure 3-32 for removal of 'fuel injection

lines.

3-39. Electrical Governor Hydraulic Actuator

Refer to figure 3-33 for removal of the hydraulic

actuator.

3-40. Mechanical Governor - Fuel Injection Pump

a. The fuel injection pump governor assembly is

lubricated through the engine lubricating system. No

lubrication service on the injection pump and governor

assembly is required.

b. Calibrating and test stands, and special tools are

required to test, adjust, and repair the fuel injection

pump and governor assembly.

Removal, testing,

adjusting and installation are to be accomplished at

Field or Depot Level.

3-41. Checking Fuel System

"Missing" or uneven running of the engine, excessive

vibration, and loss of power are indications of

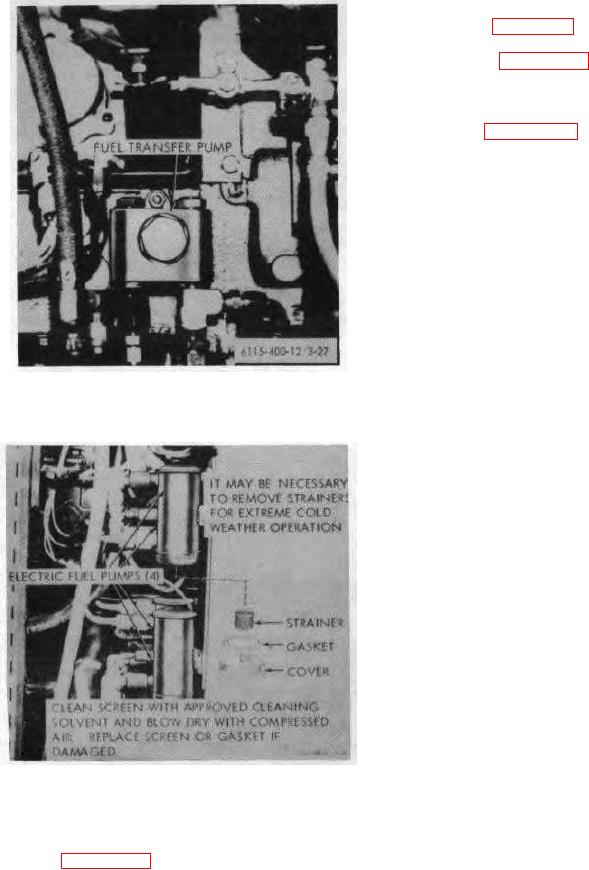

Figure 3-27. Fuel transfer pump, removal and

insufficient fuel supply to the engine. Before performing

installation.

any of the following checks, make certain there is an

ample supply of clean fuel in the fuel tank and the day

tank and that the fuel selector valve is open.

a. Check for Admission of Air Into System.

Loosen vent screw in top of fuel filter (F2, fig. 3-17)

retaining nut.

Crank engine with starter.

If fuel

containing bubbles flows from around the vent screw, air

being drawn into the system on the suction side of the

fuel transfer pump is indicated. Correct this condition by

tightening any loose low pressure fuel line connections

between day tank and fuel transfer pump.

b. Check for Clogged Fuel Filters and Clogged or

Collapsed Fuel Lines. Loosen the vent screw in top of

F2 fuel filter shell retaining nut. Crank engine with

starter. If a full flow of fuel is not obtained from around

Figure 3-28. Electric fuel pump service.

3-37. Day Tank Float Assembly

Refer to figure 3-30 for removal of day tank float

assembly.

3-36