TM 5-6115-400-12

(5) Loosen the fuel injection tube nuts from

the fuel injection line connectors.

(6) Free the injection nozzle end of the tubes

and remove the tubes from the engine.

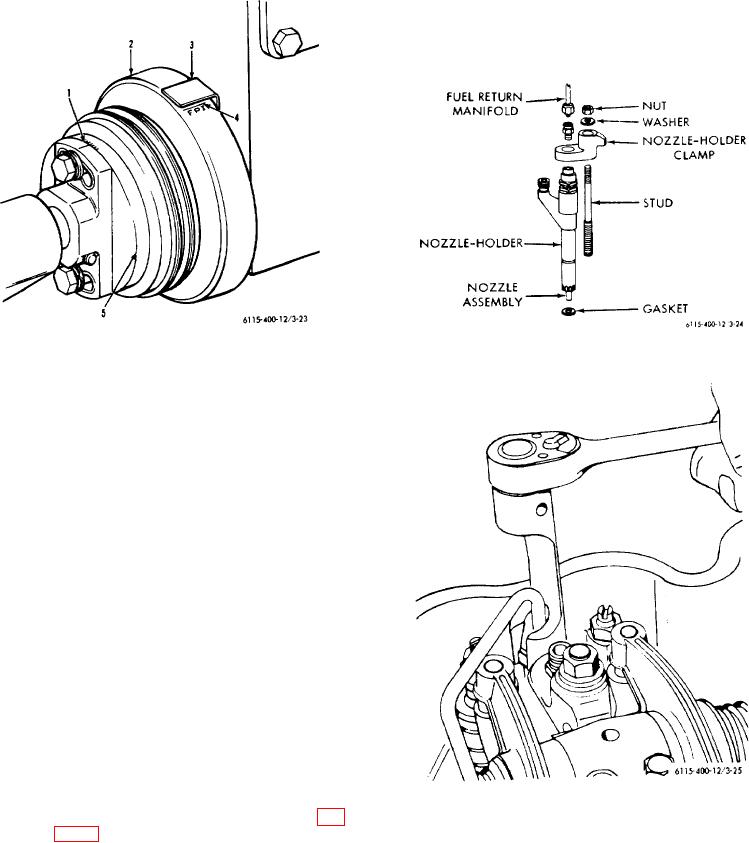

Figure 3-24. Nozzle-holder assembly.

1 Degree marks (1 marks-3 degrees) Use when

advancing or retarding pump timing to indicate

degrees changed.

2 Coupling hub

3 Timing pointer

4 FPI timing mark

5 Coupling flange

Figure 3-23. Fuel pump coupling timing marks.

holder assembly is used to hold the nozzle in its correct

position in the cylinder head and to provide a means of

conducting fuel to the nozzle. The holder assembly

consists of a holder body, spindle, spindle spring,

pressure adjusting screw, adjusting screw locknut,

protection cap, and a nozzle retaining nut. The nozzle

consists of a nozzle valve and a nozzle valve body, in

which are located four equally spaced spray orifices.

b. Removal and Installation.

(1) Thoroughly clean valve rocker covers and

surrounding area.

(2) Remove valve rocker covers.

(3) Disconnect and remove the fuel return

manifold.

Figure 3-25. Fuel injection tubes, removal and

(4) Using a fuel injection tube nut wrench (fig.

installation.

3-25), loosen the injection tube nuts from

the top of the fuel injection nozzles.

3-33